Research Article

Research Article

Proportional Examination of Pf Mechanical Composition of Concrete Produced with Washed and Unwashed Gravel

Salvador KA, Department of Building Technology, Lagos State Polytechnic, Ikorodu, Lagos, Nigeria.

Received Date: March 08, 2021; Published Date: April 6, 2021

Abstract

Concrete is a very important material in the Nigerian construction industry as over 90% of her storey buildings are made from reinforced concrete. Local gravel is being increasingly used as coarse aggregate in place of the more expensive crushed granite in the production of concrete in parts of the country where it is found. Hence, this study aims at comparing the mechanical properties of concrete produced with washed and unwashed gravel to identify the most suitable aggregate for concrete. The use of two types of course aggregates for different works is examined in this study. Typical strength concrete is being made from various aggregates and their impact on various characteristics to the subsequent concrete. Compressive strength is the most vital property of concrete. In this paper, two forms of coarse aggregates washed gravel and unwashed gravel were utilized. Sharp sand is the fine aggregate. Initial laboratory examination was carried out to establish the appropriateness of utilizing the aggregates for construction purpose. Particle size distribution (sieve analysis) and slump test were investigated. Mix ratio (1:2:4 & 1:1.5:3) was used for this work and mix structures were analyzed by absolute weight technique. A total of 25 cubes (150×150×150mm) were cast to permit the compressive strength to be observed at 7, 14 and 21 days. Test results revealed that concrete produced from unwashed gravel has better workability than washed gravel. Higher compressive strength at all periods was observed with concrete produced from washed gravel aggregate. Compressive strength patterns were suggested as a result of age at curing.

Keywords:Proportional; Pf; Mechanical composition; Concrete; Examination; Mechanical; Washed; Unwashed gravel

Introduction

Concrete is a vital material in the Nigerian construction industry as over 90% of her storey buildings are made from reinforced concrete [1]. Building structures with the right materials and proper strength characteristics would eliminate the incidences of collapsed buildings and structures in Nigeria [2]. In the same vein, in an attempt to reduce the high cost of providing housing in Nigeria, researchers are searching for less expensive alternatives to the traditional materials employed in the construction industry. Thus, local gravel is being increasingly used as coarse aggregate in place of the more expensive crushed granite in the production of concrete in parts of the country where it is found [3]. Hence, this study will focus on comparative studies on the mechanical properties of concrete produced with washed and unwashed gravel. Concrete is a stone-like material obtained by designing a carefully proportioned mixture of cement, sand, and gravel or other aggregates and water to harden in forms of the shape and dimensions of the desired structure [4]. They further stressed that aggregate is one of the important constituents in concrete, which affects strength development. Although strength depends upon many parameters such as water/concrete (w/c) ratio, aggregate gradation, aggregate size and shape, cement quality, mixing time, mix ratio, curing etc., but this study has concentrated only on the comparative performance on mechanical properties of concrete produced with washed and unwashed gravel. The study of Sharmin, Ahmed, Ahmed, & Lubna [4] recognizes that the physical characteristics of Natural (uncrushed aggregates) and artificial (crushed aggregates) as two types of coarse aggregates normally found. They however stressed that 40mm-downgraded natural stones are designated as uncrushed aggregates and that above 63 mm is termed as boulders or gravels. Boulders or gravels are broken down below 40mm size to prepare crushed aggregates. Uncrushed aggregates are semi angular or rounded, but crushed aggregates are angular. Strength being the most important property of concrete determines the quality of concrete [2]. This strength is ultimately dependent on the choice and type of aggregate. Gravels are formed from natural weathering of parent rocks and eventual transportation of the weathered products by wind and erosion. They are obtained by dredging from pit, lake, river and seabed. Their classification is usually as those having an upper (D) sieve size larger than 4mm wherein the combination of d and D indicates whether the gravel is single sized or graded (BS EN 12620). Bigger sizes can be described as pebbles, cobbles or boulders [1]. Gravels are commonly round in shape which gives rise to a lower quantity of cement paste to about 4-5% in concrete production.

Salau & Busari [5] agree with Naoum SG [6] on their study on the size of aggregate that will improve the properties of concrete and concluded that the use of quarry dust and 20mm granite improved the concrete strength by 34% over the strength produced by concrete with sand and gravel of 28mm maximum size. Srinivas K [7] undertook particle size distribution analysis, slump test and compressive strength on hardened concrete in exploiting the economics of gravel as a substitute to granite in concrete production. They found out that a higher composition of gravel significantly improves concretes’ consistency property while greater proportions of granite do significantly enhance compressive strength. Also reported that sources of gravel greatly influence the compressive, flexural, and split-tensile strength of concrete. The high cost of conventional building materials is a major factor affecting housing delivery in Nigeria. This has necessitated research into alternative materials of construction. This aspect has been the major focus of many researchers [1,3,4,8-10]. Some of the earlier studies returned a positive relationship between the composition of concrete materials and their strength while others showed a negative relationship. For instance, Olanipekun, Olusola, & Ata [9] compare concrete properties using coconut shell and palm kernel shell as coarse aggregates. This paper presents the results of an investigation carried out on the comparative cost analysis and strength characteristics of concrete produced using crushed, granular coconut and palm kernel shells as substitutes for conventional coarse aggregate in gradation of 0%, 25%, 50%, 75% and 100%. The results of the tests showed that the compressive strength of the concrete decreased as the percentage of the shells increased in the two mix ratios. However, concrete obtained from coconut shells exhibited higher compressive strength than palm kernel shell concrete in the two mix proportions. Likewise, Chen, Yen, & Chen [8] investigates the use of building rubbles as recycled aggregates using rubble collected from damaged and demolished structures. The study shows that building rubble could be transformed into useful recycled aggregate through proper processing. Using unwashed recycled aggregate in concrete will affect its strength. The effect will be more obvious at lower water/cement ratios. When the recycled aggregate was washed, these negative effects were greatly improved. This study will use the combination of literature review and practical testing in the laboratory to ascertain the effects of washed and unwashed gravel on concrete strength.

Salau & Busari [5] investigated the effect of different coarse aggregate sizes on the strength characteristics of lateralized concrete. The results of the tests showed that workability, density and compressive strength at constant water-cement ratio increase with the increase in the coarse aggregate particle size and also with curing age. As the percentage of laterite increases, there was a reduction in all these characteristics even with the particle size of coarse aggregate reduction due to loss from the aggregate-paste interface zone. This study will also determine the workability, density and compressive strength at a constant water-cement ratio in the laboratory. The work of Echeta, Ikponmwosa, & Fadipe, [3] compared the effect of partial replacement of granite with washed gravel on the characteristic strength and workability of concrete. The result shows that the workability of the concrete decreased with an increase in gravel content. Also, it was observed that for all curing ages, as the percentage replacement level increased, the compressive strength of the concrete increased to a maximum at 20 per cent replacement level. Thereafter, it decreased as the replacement level increased to 100%. Rahmani, Dehestani, Beygi, Allahyari, & Nikbin [11] also investigated the mechanical properties of concrete containing waste PET particles. The study found that fresh concretes containing PET particles presented lower workability and density. Concrete with PET particles demonstrated a lower modulus of elasticity and splitting tensile strength concerning conventional concrete. Also, the compressive and flexural strength show an ascending trend at the initial stages, however, they tend to decrease after a while. This study is however aimed at comparing the mechanical properties of concrete produced with washed and unwashed gravel in other to encourage the use of locally sourced gravel in construction works without reducing its quality and to minimize the cost of concrete within the study area.

Methods and Materials

A total of 32 number of 150mm cubes will be cast and observed for 7, 14, 21, and 28 curing days. The cubes will be weighed and crushed using the Techno test KB 1500kN capacity crushing machine in the Building Technology laboratory of Bells University of Technology, Ota. Compressive strength of concrete (7 days, 14 days, 21 days and 28 days) was determined using cube specimens as per British standard (BS-1881). Specimens with uncrushed and crushed aggregates were made. Weight batching of normal strength concrete 1:2:4 complying to a standardized prescribed concrete mix ST4 with an expected target strength of 20kN (BS 8500-1:2002 and BS 8500-2: 2002) and S2 slump will be attained with a predetermined water-cement ratio. Slump tests for concrete separately with unwashed and washed gravel with the same slump (38 mm or 1.5 inches) was performed to determine the w/c ratio. A Standard test method ASTM C127 was used for the determination of specific gravity and absorption of coarse aggregates. Standard test method ASTM C128 was used for the determination of specific gravity and absorption of fine aggregates. Standard test method ASTM C136 will be used for sieve analysis of fine and coarse aggregates (washed and unwashed).

Findings and Discussion

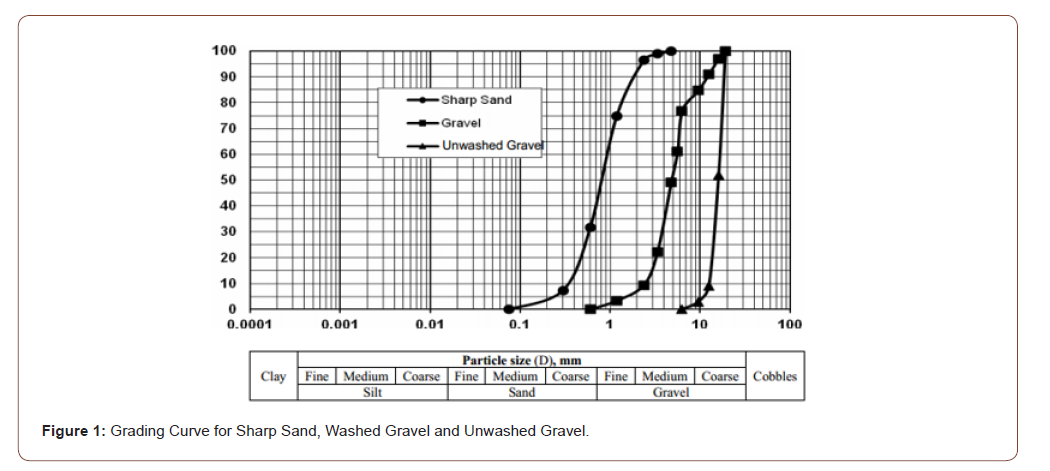

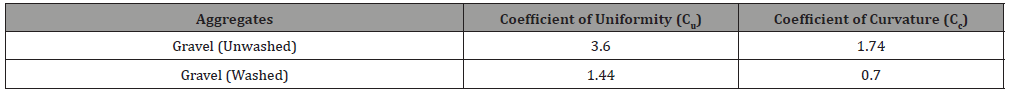

The result of the finding in Table 1, shows the grading curves obtained for the sand, washed gravel and unwashed gravel respectively. The results of preliminary tests on the concrete constituent materials showed that the washed coarse aggregate ranged in particle sizes from 4.3 to 19.0 mm. The gradation of the coarse aggregates and coefficient of uniformity (Cu) and Coefficient of curvature (Cc) following BS EN 933-1:2012 (Table 1, Figure 1).

Table 1:Physical Properties of the Aggregates.

The washed gravel is poorly graded but more uniformly graded because the coefficient of uniformity (Cu) is close to one and unwashed gravel is uniformly graded with a coefficient of uniformity (Cu) and Coefficient of curvature (Cc) approximately four and two respectively (see figure 1). However, the aggregates are suitable for construction project works. This study is similar to results obtained in Salau & Busari [5] (Tables 2,3).

Table 2:Slump Test.

Table 3:Slump Test.

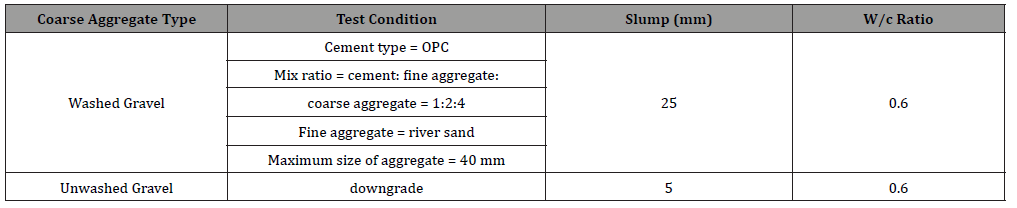

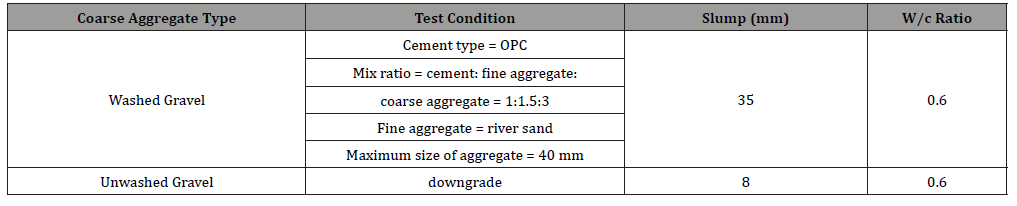

The results of the slump test undertaken in Table 2 showed that all the mixes indicated true slump, irrespective of the type of gravel (Washed or Unwashed gravel). Using washed gravel, the concrete mix gave a slump value of 25 mm. The slump decreased to 5mm as the aggregate was changed to unwashed gravel. This could be adduced to the fact that the unwashed gravel contains more fines than the washed gravel hence the increased surface area that requires higher water demand to be more workable. Also, a comparison of the grading curves for unwashed gravel and washed gravel (see Figure 1) shows that the unwashed gravel particles are generally finer and contains some kind of impurities than those of washed gravels. For the same weight, therefore, the unwashed gravel possesses a greater surface area than the washed gravel. Hence more water is required to saturate the aggregate, and the result is that the workability of the concrete is reduced. Table 4 depicts the results of cube crushing at 7, 14, and 21 days respectively for four (4) different cubes of the same mix ratio and water-cement ratio (Table 4).

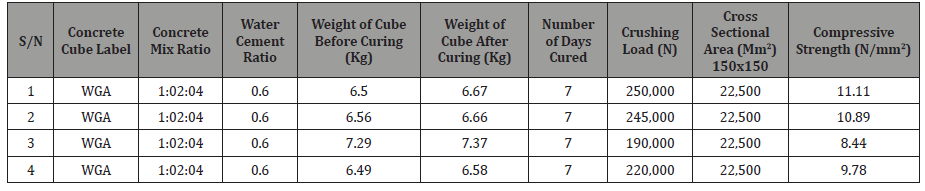

Table 4:Compressive Strength Test-Result Sheet (Washed Gravel-7days).

The table indicates that there is a slight increase in the weight of cubes after and before curing. This may be due to the presence of water in the cube specimen after curing. However, the crushing loads differ with the same cross-sectional area with minimum compressive stress of 8.44 N/mm2 – 11.11 N/mm2 indicating an average mean of 10.06 N/mm2. The difference in the compressive strength results may be due to inadequate tamping (rodding) and compaction of the specimen [12-25].

Conclusion

Based on the result of these findings. The following conclusion was drawn:

1. Gravels will require more water to be workable hence could be adduced for reduced compressive strength. However, unwashed gravel is not suitable for the construction of structural members in a multi-storey building.

2. From the sieve analysis, decomposable materials and other specks of dirt were observed in the gravel that could potentially affect the strength development of the concrete. Also, very fine particles were observed which could be silt, clay and humus.

3. Concrete prepared with washed gravel achieved better compressive strength than those made with unwashed gravels. This study validates the existing studies [1,5]. This reason may be as a result of the removal of decomposable materials and other specks of dirt were observed in the gravel during washing. Also, the findings will serve as practical importance to stakeholders in the construction industry (i.e., contractors, clients, government, policymakers, and so on) that could adequately adjust their implementation and development plans based on the results of the study.

Acknowledgement

None.

Conflicts of Interest

No conflict of interest.

References

- Nduka DO, Fabgenle OI, Joshua O, Ogunde AO, Omuh IO (2018) Comparative Analysis of Concrete Strength Utilizing Quarry-Crushed and Locally Sourced Coarse Aggregates. International Journal of Mechanical Engineering and Technology 9(1): 609–617.

- Umeonyiagu IE, Nwobi-Okoye CC (2015) Predicting Flexural Strength of Concretes Incorporating River Gravel Using Multi-Layer Perceptron Networks: A Case Study of Eastern Nigeria. Nigerian Journal of Technology (NIJOTECH) 34(1): 12-20.

- Echeta CB, Ikponmwosa EE, Fadipe AO (2013) Effect of Partial Replacement of Granite with Washed Gravel on the Characteristic Strength and Workability of Concrete. ARPN Journal of Engineering and Applied Sciences 8(11): 954-959.

- Sharmin R, Ahmed DM, Ahmed M, Lubna FA (2006) Comparison of Strength Performance of Concrete with Uncrushed or Crushed Coarse Aggregates. ARPN Journal of Engineering and Applied Sciences 1(2): 1-4.

- Salau MA, Busari AO (2015) Effect of Different Coarse Aggregate Sizes on the Strength Characteristics of Laterized Concrete. 2nd International Conference on Innovative Materials, Structures and Technologies IOP Conf. Series: Materials Science and Engineering 96(012079): 1-8.

- Naoum SG (2007) Dissertation Research and Writing for Construction Students. Butterworth-Heinemann.

- Srinivas K (2016) What is the workability of concrete? Quora.

- Chen HJ, Yen T, Chen KH (2003) Use of building rubbles as recycled aggregates. Cement and Concrete Research. pp.125–132.

- Olanipekun E, Olusola K, Ata O (2006) A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Building and Environment 297–301.

- Nwobi-Okoyea C, Umeonyiagub I, Nwankwo C (2013) Predicting the Compressive Strength of Concretes Made with Granite from Eastern Nigeria using Artificial Neural Networks. Nigerian Journal of Technology (NIJOTECH) 32(1): 13-21.

- Rahmani E, Dehestani M, Beygi M, Allahyari H, Nikbin I (2013) On the mechanical properties of concrete containing waste PET particles. Construction and Building Materials 47: 1302-1308.

- Brady GS, Clauser HR, Vaccari JA (2018) Materials Handbook (Fifteenth Edition ed.) McGraw-Hill Handbooks.

- Designing Buildings Ltd. (2018) Gravel in construction. Designing Buildings Wiki.

- ECO serve Network (2004) Cluster 3: Aggregates and Concrete Production. Baseline Report for the Aggregate and Concrete Industries in Europe, The Icelandic Building Research Institute.

- Kochyil S, Little DN (2018) Physical, Mechanical and Chemical Evaluation of Manufactured Aggregate. Texas: Texas Transportation Institute, Texas A&M University, College Station.

- Kourd A, Hammad A (2010) Cement and Concrete Technology. Gaza: Islamic University of Gaza, Faculty of Engineering, Civil Engineering Department, Materials & Soil Labs.

- Kozul R, Darwin D (1997) Effects of Aggregate Type, Size, and Content on Concrete Strength and Fracture Energy; Kansas: A Report on Research Sponsored by the National Science Foundation the US Department of Transportation Federal Highway Administration the Reinforced Concrete Research Council.

- Meyer C (2003) Guide to the Selection and Use of Hydraulic Cement: American Concrete Institute. Encyclopedia of Science & Technology, 10th Edition. Copyright, The McGraw-Hill Companies, Inc.

- Nemati KM (2015) Properties of Fresh Concrete. Washington: University of Washington. Retrieved September 27, 2018

- Pereiraa D, Aguiar Bd, Castro F, Almeida M, JL (2000) Mechanical behaviour of Portland cement mortars with incorporation of Al-containing salt slags. Cement and Concrete Research, 30: 1131–1138.

- Quora (2019) what is flexural strength of concrete, and how is it calculated? Quora Online Dictionary.

- The Concrete Countertop Institute (2018) The Importance of Water/Cement. The Concrete Countertop Institute.

- The Working Group on Review of CS1 (2010) Testing Concrete. The Government of the Hong Kong Special Administrative Region. Hong Kong: Standing Committee on Concrete Technology (SCCT).

- Unknown author (2018) October 1 construction equipment’s and practice.

- Unknown Author (2018) Building Materials 10-Testing Methods, Aggregates.

-

Salvador KA, Amusu OR. Proportional Examination of Pf Mechanical Composition of Concrete Produced with Washed and Unwashed Gravel. Cur Trends Civil & Struct Eng. 7(1): 2021. CTCSE.MS.ID.000652.

-

Proportional, Pf, Mechanical composition, Concrete, Examination, Mechanical, Washed, Unwashed gravel, Aggregates, Building rubbles

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.