Research Article

Research Article

Investigation of the Effect of Steel Fibers on the Thermal Behavior of Fibrous Concrete under FEM Finite Element Analysis

Seyed Ali Mousavi Davoudi, Graduate of Master of Structures, Faculty of Civil Engineering, Tabari Higher Education Center, Iran.

Received Date: June 03, 2022; Published Date: June 22, 2022

Abstract

With the passage of time and the increase in world population, the need for progress in the field of construction, maintenance, and retrofitting of existing structures and the use of new technologies is felt more than ever. Fiber concrete is a type of composite that increases tensile strength by using reinforcing fibers inside the concrete mix. This composite composition has good integrity and cohesion and allows the use of concrete as a formable material to produce high-strength curved surfaces. Fiber concrete also has a high energy absorption capacity and does not disintegrate easily under impact loads. The historical evidence of this technology is the use of thatch in buildings to replace concrete fibers. Fiber concrete is an advanced type of this technology in which new natural and synthetic fibers have replaced straw, and cement has replaced mud used in straw. Fiber concrete has suitable properties such as high ductility, excellent strength, energy absorption, and cracking stability, which can be used for many applications. Therefore, in this study, to investigate the effect of steel fiber percentage on the thermal behavior of fibrous concrete under finite element analysis, four study samples with a fiber content of 0 to 1.5% were used. For numerical modeling, Abaqus finite element program was used. From modeling and numerical analysis, it was concluded that the effect of steel fibers in the concrete mixing design reduces the heat caused by the hydration of cement and improves the performance of concrete.

Keywords: Fiber concrete; Steel fibers; Numerical analysis; Finite elements

Introduction

In the manufacture of fiber concrete, composites are used as a new technology in the construction industry. Concrete additives and reinforcing fibers are among the new materials that have a special place in construction. These materials improve the desired properties of concrete, such as its strength, and in some cases, by reducing the weight of concrete, very light materials are offered to building engineers. [1] From 1960 onwards, a new type of concrete entered the industrial field. In this way, this type of concrete is used separately with random distribution as a new phase in addition to ordinary concrete phases. The tensile and shear strength of fibrous concrete is higher than ordinary concrete. [2] In addition to being sufficient against static and dynamic loads, the final thickness of fibrous concrete creates very high reliability in execution. It is more important in underground structures that are exposed to more water, moisture, and corrosion. In addition, fiberreinforced concrete performs much better against dynamic loads such as earthquakes and shocks due to its good energy absorption properties. [3]. This major defect of concrete is practically solved by reinforcing it with steel rebars or reinforcement. But since reinforcement is exclusively a small part of the section, it would not be correct to assume that the concrete section is anisotropic and homogeneous. To create isotropic conditions and also to reduce the fragility and brittleness of the concrete body as much as possible in recent decades, thin and relatively long strands are used that are homogeneously scattered throughout the concrete volume. The use of such filaments in concrete and in general in cement mortars that can be used can be fibers of glass, polyethylene, steel, asbestos, or nylon [4] (Figure 1).

In ancient times, fibers were used to strengthen brittle mortars. The most famous and popular one, which is available due to its cheapness, is straw, which is used to strengthen bricks and thatch mortars in coatings against cracking after drying. It is created, used, and is currently the cheapest type of mortar in rural areas of the country. The use of straw, especially ponytails or goat hair in ancient Iranian buildings, especially domes, has a long and historical history that shows the insight and knowledge of technicians about fibers. The use of steel fibers began in the middle of the last century and the exact date of use of this method is not available, but different people use different methods such as the use of wire pieces or metal cuts in concrete, the advantages of this method in their name Rasandehand [5]. Unlike ordinary concrete, these materials can withstand considerable tensile stresses and strains at tensile loads and can be used in the design. In these materials, cracking is out of the state of concentrated cracks and has appeared in the form of multiple cracks. This behavior has significant effects on increasing the ductility of members and more importantly on the reliability of concrete structures. Relying on the strain capacity of these materials under pressure, the amount of enclosing reinforcement in compressive areas can be reduced. Shear strength in these concretes and their behavior is such that shear reinforcement can be eliminated. Other advantages of using these materials include ductility in seismic members, increasing the number of inelastic deformations, not reducing the resistance, and maintaining integrity in these deformations, which leads to achieving damaging behavior. These materials have great potential for use in energy-absorbing elements as a passive control in building seismic improvement [6]. A clear advantage of fiber concrete is its high working capacity. Work capacity in this text means the capacity of an object to convert external work into:

1. Storage energy can be changed

2. Internal work is the formation of new cracks by the release and

deformation of fibers or the production of heat.

The flexibility of fibrous concrete, like the properties of plastic materials, ensures that fibrous concrete does not have a sudden rupture. Because steel fibers are dispersed three-dimensionally, or rather multidimensionally, in the concrete body, forming a crack that is usually expected to deform in various directions creates bonding fibers and prevents the crack from spreading; Therefore, fiber fibers actively play a role in limiting the width of cracks and thus increase the usability of concrete by forming many fine cracks [7,8].

Dehghani Conducted a study on steel fiber concretes. In this study, they stated that in recent years, advances in concrete technology have resulted in the production of high-strength, highstrength concrete. The two main characteristics of the cement body with a compressive strength of more than 150 MPa and having a ductile behavior due to the presence of fibers, make superstrong concrete stand out from other types. Concrete structures experience different temperature conditions during their lifetime and these cases have a direct effect on the mechanical properties and durability of concrete. These effects can include changes in the temperature of the natural atmosphere or abnormal conditions such as fire. Therefore, it is very important to study the effects of temperature on concrete, especially high-strength concrete, which is expected to have high strength. In this research, the thermal properties of a type of super-capable concrete reinforced with steel fibers have been investigated by calculating the coefficient of thermal expansion and high heat resistance. The coefficient of thermal expansion of high-strength concrete is higher than that of high-strength concrete and the values reported for ordinary concrete. In the heat test in non-dried samples, the resistance of the samples decreased with increasing temperature to 400 °C. In dried samples, the sensitivity of superconducting concrete to heat is higher than that of concrete [9]. Badra et al. [6] Conducted a study on steel fiber concretes to investigate the effect of steel fibers on the physical and mechanical properties of fiber concrete. Fiber concrete is a type of concrete that is made of fibers and uses cement, water, aggregates, and additives. Together with the fibers on the physical and mechanical properties of the fiber concrete are mixed, including strength. Percentage and ratio of length to the diameter of steel fibers and strength factor of fiber concrete, flexural strength, tensile strength, shear strength, compressive strength, dynamic strength, fatigue strength, torsional strength, crack resistance, creep, fiber rot and rust, thermal conductivity, Abrasion resistance and frictional and sliding resistance are effective. The flexibility of fibrous concrete, like the properties of plastic materials, ensures that fibrous concrete does not have a sudden rupture and can be used as an alternative to conventional reinforced concrete. This study introduces fiber concrete, the application of the study of the effect of steel fibers on the physical and mechanical properties of fiber concrete [6].

Research Methods

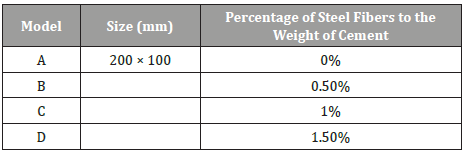

To investigate the effect of steel fiber percentage and the effect of fiber concrete heat hydration under FEM finite element analysis, in this study, 4 cubic samples with dimensions of 200mm × 100mm with zero to 1.5% fiber percentage are used. It should be noted that all samples by the program Abacus will be modeled and analyzed. Table 1 presents the specifications of the tested models and the effective parameters (Table 1).

Table 1:Details of study samples.

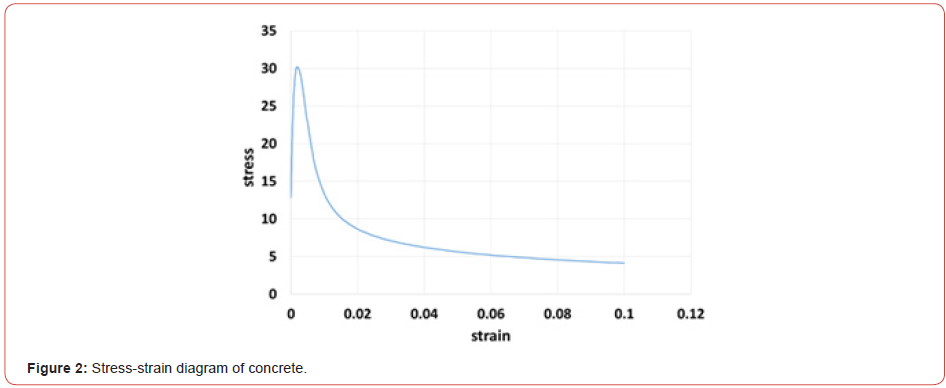

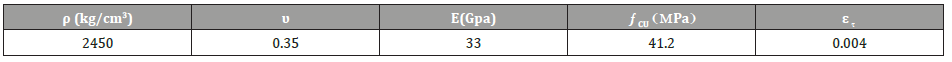

In this research, concrete with a compressive strength of 30 MPa has been used, whose behavior follows the properties of elastic and plastic. Figure 2 shows the stress-strain diagram of concrete (Figure 2, Table 2).

Table 2:Detail of concrete.

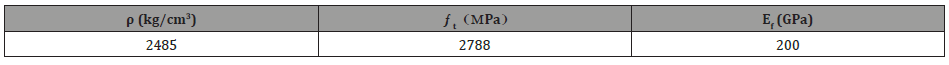

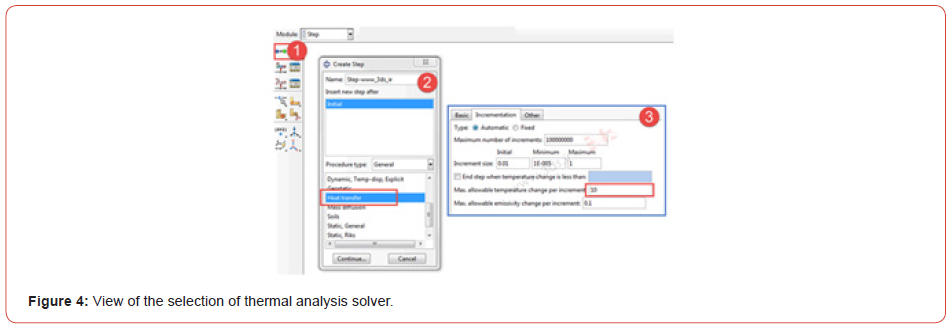

Tables 3 & 4 provide the mechanical and physical characteristics of the steel fibers used in concrete, including diameter and length (Tables 3 & 4).

Table 3:Detail of steel fibers.

Table 4:Detail of steel fibers.

Modeling Process

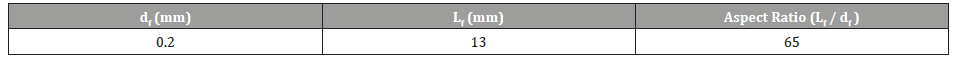

The solid element was used to model the concrete and the wire element was used to model the steel fibers. Also, the mechanical properties of steel fibers with a tensile strength of 2788 MPa have been used, and concrete with a compressive strength of 30 MPa has been used. Also, to define the connection and constraints of the surface status of all pages that are in contact with each other, the contact constraint was used as a level to level. For connection between concrete and steel fibers inside the concrete, the contact type of embedded region type is used (Figure 3).

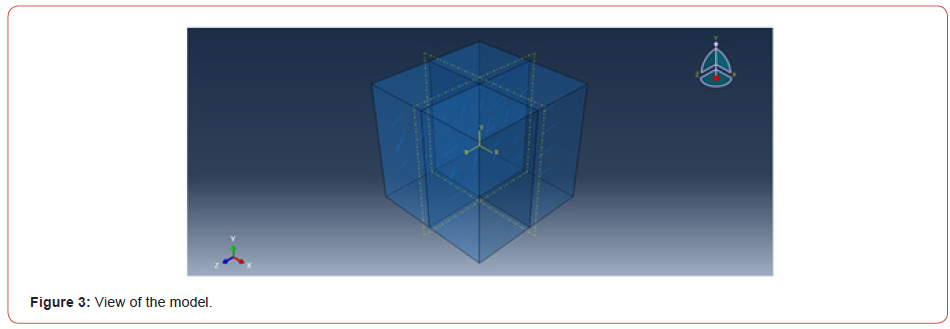

To perform thermal analysis by assembling the model in the Assembly environment, follow the work in the Abaqus Step module. Due to the nature of the problem, a heat transfer solvent is selected for the analysis of its finite components, and the maximum temperature change in each step is considered to be 10 units (Figure 4).

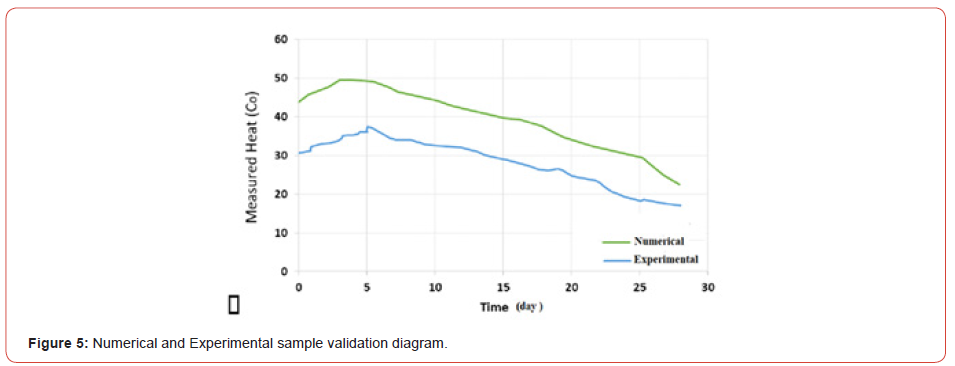

For the accuracy of the software sample of the Abaqus program, laboratory studies of Sarabi et al. [8] were used. It is about 12.5%, Figure 5 shows the time-temperature hydration validation diagram of laboratory and numerical samples (Figure 5).

Model networking According to the type of sensitivity analysis, the size of the allocated networks was considered to be 50 mm, Figure 6 shows the networking method (Figure 6).

Analysis Results

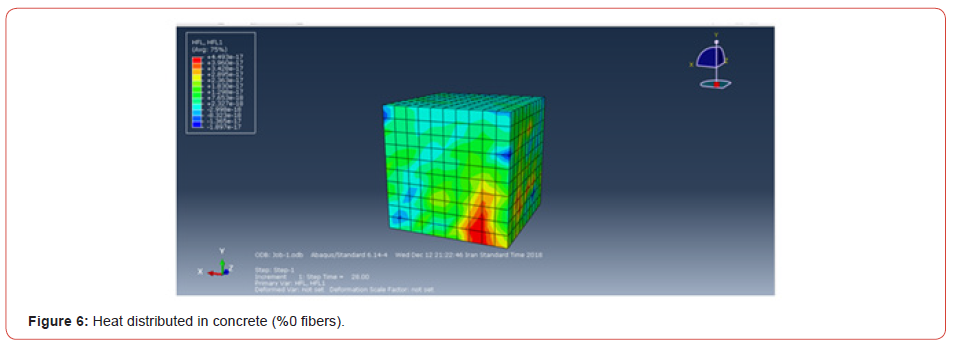

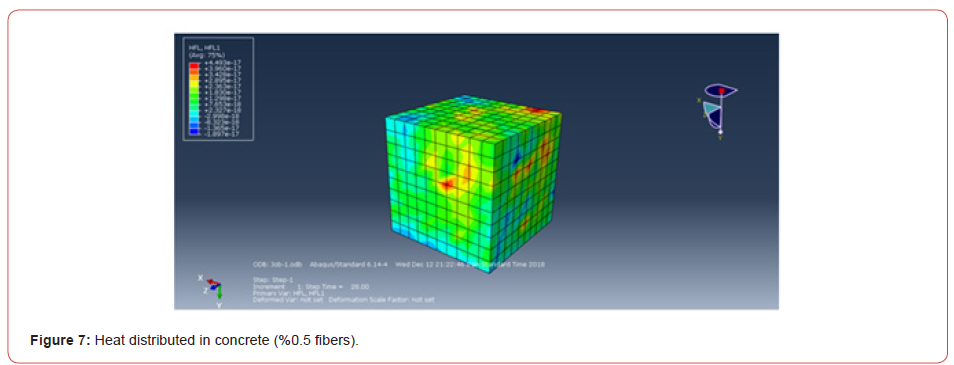

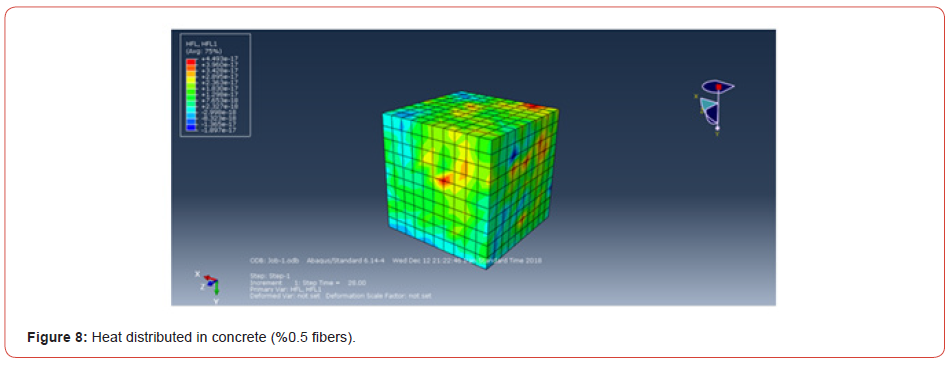

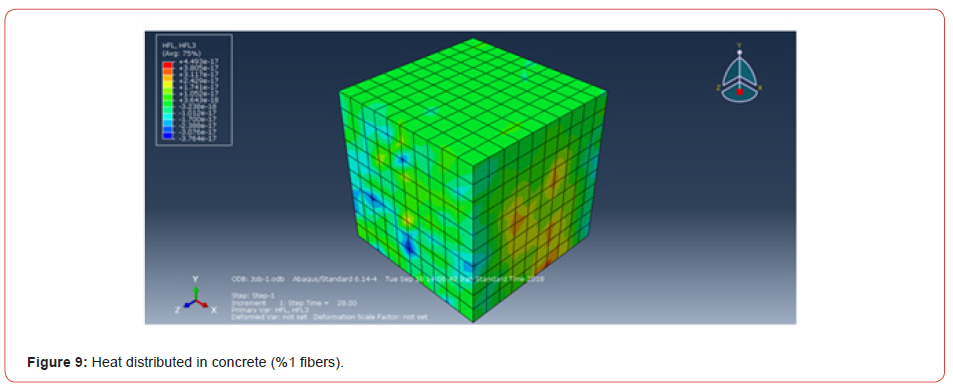

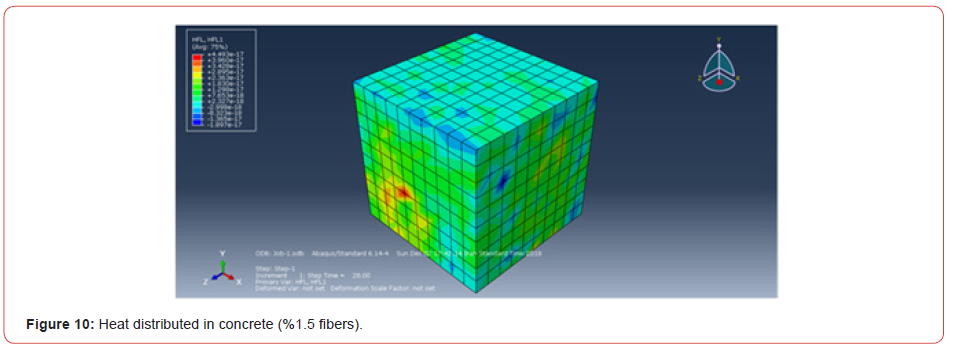

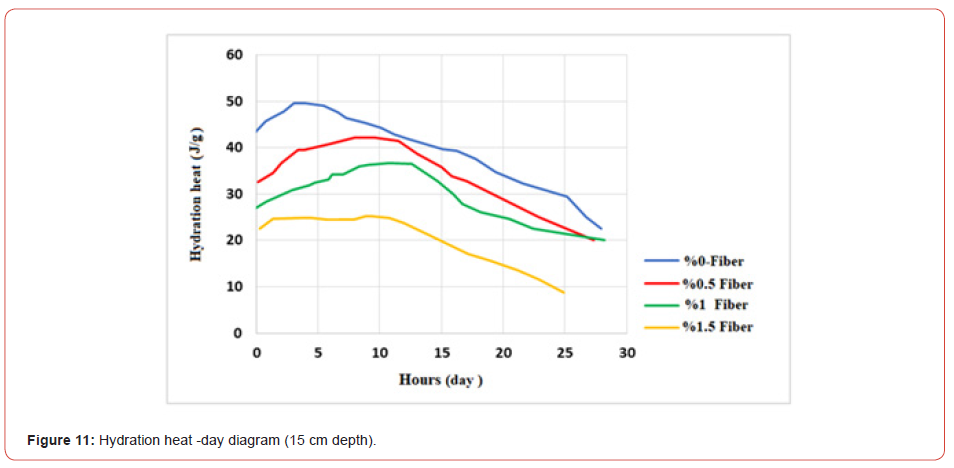

After performing thermal analysis of model, A without fibers, model B with 0.5% fiber percentage, model C with 1% fiber percentage, and model D with 1.5% fiber percentage was performed. In the isolation environment, diagrams of different analytical parameters can be seen. In the following, the results will be compared by examining the hydration-day temperature diagram of the samples. After performing finite element analysis, the amount of hydration heat generated in concrete for different percentages of fibers is presented (Figures 7-10).

Analysis results at a depth of 5 cm

By comparing this diagram of hydration temperature-study time A, B, C, and D is observed at a depth of 5 cm, in the sample without fibers, the hydration temperature is much higher than in the samples with fibers, also by comparing the sample B (fibers 0.5%) and sample C (1% fiber) was observed that with an increase of 0.5% in the number of fibers from sample B compared to sample C, it was observed that the heat of hydration decreased by 12.3% at a depth of 5 cm, also by comparing sample B And D was observed with an increase of 0.5% in the number of fibers witnessed a decrease in hydration temperature of 14.5% at a depth of 5 cm (Figure 11).

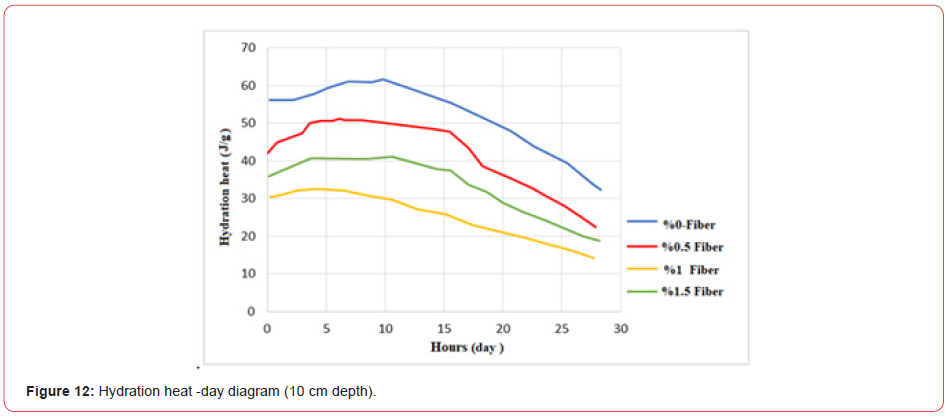

Analysis results at a depth of 10 cm

By comparing the hydration-temperature diagram of study samples A, B, C, and D at a depth of 10 cm, it is observed that in the sample without fibers, the percentage of hydration heat is much higher than in the samples with fibers, ie, on average, compared with sample B ( Fibers 0.5%) and sample C (1% fibers) are observed, which with a 0.5% increase in the number of fibers from sample B to sample C is observed that the heat of hydration is reduced by 9.5% at a depth of 10 cm, also with Comparison of samples B and D (1.5% fibers) was observed by increasing the number of fibers by 75%, causing a decrease in hydration temperature to 17.37% at a depth of 10 cm (Figure 12).

Analysis results at a depth of 20 cm

Anxiety has risen during the Covid10 pandemic [1]. When people enter the workplace, they do not leave their emotions behind, and emotions influence how people work. Anxiety is an emotion that underpins much behaviour in organisations and eemployees experiencing anxiety double the risk of poor work performance and productivity [2,3]. It is highly personalized, varying widely by individual and occurring as the result of a stimulus that triggers automatic responses, normally fear, panic, and worry. When fear, panic or worry is experienced, subconscious structures can trigger repeated automatic responses until neural patterns or behaviours are subconsciously modified [4]. Subconscious solutions exist, but they may not be known about or well understood. Hypnotherapy is a solution that has been clinically trailed to deal with anxiety but has not yet been widely adopted in workplaces where anxiety has a productivity impact [5]. Understanding what perceptions and barriers to this practice exist with workplace mental health providers was important as an aim for this research. Anxiety is a constant state – at

Conclusion

In this study, in order to investigate the effect of steel fiber percentage on the mechanical behavior of fiber concrete under finite element analysis, 4 cubic samples with dimensions of 200 mm × 200 mm with a fiber content of zero to 1.5% were used. After numerical analysis, the following results were obtained:

1. Adding steel fibers reduces the hydration temperature so that by increasing the number of fibers by 0.5% in each step, the hydration heat will decrease by an average of 13.45%.

2. With increasing depth, the amount of hydration heat generated in the samples increases. On average, with an increase of 5 cm in each stage, the amount of hydration temperature increased by about 12.34% on average.

3. The highest hydration temperature for the fiber-free sample

occurred at a depth of 5 cm on the third day at 50.87 °C, also the

lowest temperature at a depth of 5 cm for the fiber-free sample

on the 28th day with a temperature of / 45. 23 degrees Celsius

occurred. Comparing the above diagram, it was observed

that the percentage difference between the maximum and

minimum heat in the concrete sample was 46%.

4. The highest hydration temperature for the fiber-free sample at

a depth of 10 cm occurred on the tenth day at 62.43 °C, and also

the lowest temperature at a depth of 10 cm for the fiber-free

sample on the 28th day with a temperature of 32.74 °C. Celsius

occurred. Comparing the above diagram, it was observed

that the percentage difference between the maximum and

minimum heat in the concrete sample was 51%.

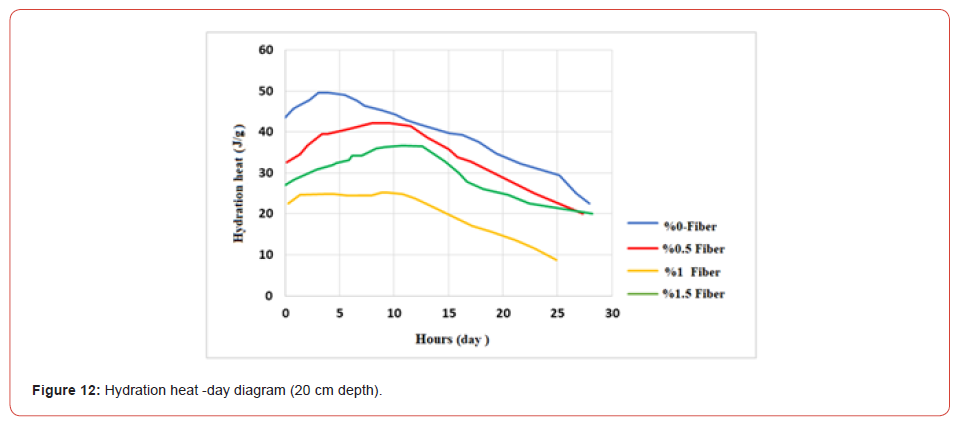

5. The highest hydration temperature for the fiber-free sample

occurred at a depth of 20 cm, such as on the eighth day with

76.96 °C, and also the lowest temperature at a depth of 20 cm

for the fiber-free sample on the 28th day with a temperature

of 35.96 °C. Celsius occurred. Comparing the above diagram,

it was observed that the percentage difference between the

maximum and minimum heat in the concrete sample was

46.36%.

6. The highest hydration temperature for the sample with (5%

fibers) at a depth of 5 cm occurred on the eighth day at 42.76

°C, also the lowest temperature at a depth of 5 cm with (5%

fibers) occurred on the 28th day Occurred with a temperature

of 20.63 °C. Comparing the above diagram, it was observed

that the percentage difference between the maximum and

minimum heat in the concrete sample was 47.85%.

7. The highest hydration temperature for the sample with (5%

fibers) at a depth of 10 cm occurred on the seventh day at

51.37 °C, also the lowest temperature at a depth of 10 cm with

(5% fibers) occurred on the 28th day with The temperature

occurred at 24.37 °C. Comparing the above diagram, it was

observed that the percentage difference between the maximum

and minimum heat in the concrete sample was 47.42%.

8. The highest hydration temperature for the sample with (5%

fibers) at a depth of 20 cm occurred on the ninth day at 59.37

°C, also the lowest temperature at a depth of 20 cm with

(5% fibers) occurred on the 28th day with The temperature

occurred at 29.54 °C. Comparing the above diagram, it was

observed that the percentage difference between the maximum

and minimum heat in the concrete sample was 49.75%.

9. The highest hydration temperature for the sample with (1%

fibers) at a depth of 5 cm occurred on the thirteenth day at

37.45 °C, also the lowest temperature at a depth of 5 cm

with (1% fibers) occurred on the 28th day. M occurred with

a temperature of 20 °C. Comparing the above diagram, it

was observed that the percentage difference between the

maximum and minimum heat in the concrete sample was 54%.

10. The highest hydration temperature for the sample with (1%

fibers) at a depth of 10 cm occurred on the eleventh day at

41.69 °C, also the lowest temperature at a depth of 10 cm with

(1% fibers) occurred on the 28th day with The temperature

occurred at 19.72 °C. Comparing the above diagram, it was

observed that the percentage difference between the maximum

and minimum heat in the concrete sample was 46.32%.

11. The highest hydration temperature for the sample with (1%

fibers) at a depth of 20 cm occurred on the eighth day at 50.37

°C, also the lowest temperature at a depth of 20 cm with (1%

fibers) occurred on the 28th day Occurred with a temperature

of 23.46 °C. Comparing the above diagram, it was observed

that the percentage difference between the maximum and

minimum heat in the concrete sample was 46.98%.

12. The highest hydration temperature for the sample with (1.5%

fibers) at a depth of 20 cm occurred on the eighth day at 25.91

°C, also the lowest temperature at a depth of 20 cm with (1.5%

fibers) occurred on the 25th day with a temperature of 8.67

°C. Comparing the above diagram, it was observed that the

percentage difference between the maximum and minimum

heat in the concrete sample was 32.57%.

13. The highest hydration temperature for the sample with (1.5%

fibers) at a depth of 10 cm occurred on the fifth day at 23.86

°C, as well as the lowest temperature at a depth of 10 cm with

(1.5% fibers) on the 28th day occurred with a temperature of

17.68 degrees Celsius. Comparing the above diagram, it was

observed that the percentage difference between the maximum

and minimum heat in the concrete sample was 53.89%.

14. The highest hydration temperature for the sample with (1.5%

fibers) at a depth of 20 cm occurred on the eighth day at 40.34

°C, also the lowest temperature at a depth of 20 cm with (1.5%

fibers) occurred on the 28th day with a temperature of 19.26

°C. Comparing the above diagram, it was observed that the

percentage difference between the maximum and minimum

heat in the concrete sample was 49.79%.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Sun W, Chen H, Luo X, Qian H (2015) the effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance

- Banthia N, Duby A (2015) Measurement of flexural Toughness of Fibre Reinforced Concrete Using Technique, Part 2, Performance of various Composites, ACI Material Journal, 97(1).

- Songa PS, Hawang S, Sheu BC (2015) Strength properties of nylon and polypropylene Fibre Reinforced Concrete, Cement &Reserch 35: 1546-1550.

- Yeol C, Robert Y (2015) experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC, Cement & Concrete Research 35: 1587-1591.

- Chunxiang Q, Piet S (2014) Fracture Properties of concrete reinforced with steel-polypropylene hybrid fibre, Cement & Concrete 22: 343-351.

- Atef B, Ashraf FA, Andrew KP (2015) Statistical variations in impact resistance of polypropylene Fibre Reinforced Concrete, International Journal of impact Engineering.

- Cheon-Goo H, Yin-Seongr H (2014) Performance of spalling resistance of high performance concrete with polypropylene fibre contents and lateral confinement, Cement & Concrete Research 35: 1747-1753.

- Sahar S, Hossein B, Hamed S, Hamed Safaye N (2017) Thermal stress control using waste steel fibers in massive concretes, Eur Phys J Plus 132: 491.

-

Seyed Ali Mousavi Davoudi. Investigation of the Effect of Steel Fibers on the Thermal Behavior of Fibrous Concrete under FEM Finite Element Analysis. Cur Trends Civil & Struct Eng. 8(5): 2022. CTCSE.MS.ID.000700. DOI: 10.33552/CTCSE.2022.08.000700.

-

Fiber concrete, Steel fibers, Numerical analysis, Finite elements, Finite element analysis, Construction industry, Tensile stresses

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.