Opinion

Opinion

Electroimpulse Device for Manufacture of Continuous Flight Augering Piles

Nikolay Sokolov1,2*

1FSBOU “Chuvash State University, Russia

2FORST LLC, Kalinina Street, Cheboksary, Chuvash Republic, Russia

Nikolay Sokolov, FSBOU “Chuvash State University, IN Ulyanov 428015, Moscow Ave, Russia.

Received Date: July 13, 2020; Published Date: August 7, 2020

Abstract

The developed electric pulse installation (EPU) is unique and novel in the technical solution for use in the installation of flight augering piles (piles-EDT). The installation of the EPU makes it possible to produce pile-EDT of increased bearing capacity. Due to the presence of a high-energy capacitive accumulator with a switch that is connected to the discharger of the radiator of accumulated energy, the EPU is an original electrotechnical structure. It is a unique high-performance aggregate for the construction of piles of increased load-bearing capacity, as well as cementation of bases. The device has no analogues abroad. It is found wide application in geotechnical construction when erecting piles-EDT in pile fields, fencing of pits, cementation of bases, etc.

Keywords: Energy capacity; Pace voltage; Unit of synchronization; Continuous flight augering pile; Electro-hydraulic shock; Electro - discharge technology; Piles-EDT; Thrust bearing

Introduction

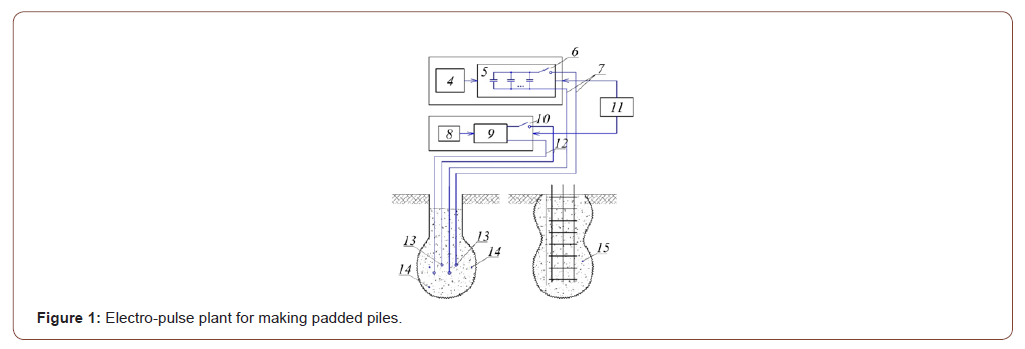

Ensuring the reliable operation of the underground part of buildings and structures, erected in difficult engineering and geological conditions, is a very urgent task of modern geotechnical construction. In such non-standard construction conditions, the most acceptable deep structures are drilling piles, which are currently arranged by geotechnical technologies. The technology developed by the authors of the article on the construction of drills is widely introduced into the practice of erecting underground structures and artificial bases for industrial and civil facilities. The technical solution under consideration, being unique to deep-duty structures, ensures the task of creating conditions for safe and reliable operation of drill-injecting piles-ERT when using an electric pulse plant. The main achievement of the developed device is to improve the reliability of the device and electrical safety during the work on the device of drills in pile fields, fencing pits, ground anchors, as well as cementing bases. When it works, the drive’s working voltage is reduced to activate the emitter. The possibility to achieve such a result is the presence of a bit of electrical impulse in the device. It has a high-energy cap-drive with a switch. It’s connected to the discharger. The additional initiating electrode is deployed in the discharger and connected via another switch to a low-power high voltage source. Both devices are connected sequentially through the synchronization unit. The device is made with the possibility of simultaneous switches. The capacitive electric pulse storage is made in low voltage and is attached with a low-voltage cable to the emitter. The algorithm for the operation of an electrical propulsion system is the following technological sequence. In a pre-made drill well 1 is filled with fine-grained concrete 2 and mounted armoarkas is immersed emitter 3 with feeding low-voltage cable 7. It is connected to the 5-unit power plant (RIA) energy storage. The elec-tric power storage 5 is charged to a low voltage of about 1000 B power capacity of about 20-50 kJ. At the same time, the low-power high-voltage source 9 to the voltage of 5-15 kV from the charging and straightening device 8 is charged. Next, a series of synchronized drives pulses 5 and 9 through cables 7 and 12 switches 6 and 10 on discharge 3 and an additional initiating electrode 13 are delivered. The synchronicity of switches 6 and 10 is provided by the 11 synchronization unit. A series of low-voltage discharges of the main capacitive energy storage 5 is produced by using the breakdown of the initiating discharge of the capacitive drive 9 through electrode 13 in the formation of the electrical discharge of 14 discharge 3. At the same time, only the simultaneous supply of a series of pulses from drives 5 and 9 in discharge 3 leads to a breakdown of a bit interval. This contributes to the appearance of electrohydraulic shocks, which affect the fine-grained concrete 2 and the ground walls of the drilling well 1, increasing its diameter, compacting the hardening material 2 and forming part of the piles 15. When a low voltage is considered to be in the range of up to 1000 B1,8,, 9,there will be no electrical breakdown on the discharger, as the voltage is not sufficient to overlap the gap, even if there is a quasi-conductive environment between the discharger electrodes in the form of “pollution” in the form of “pollution”-1, 2.

It is known that in terms of energy release in the electrical hydraulic effect, the distance between the electrodes should be about 10-20 mm on the surface of the dielectric. The high voltage of the burning pulse is also safe, as the energy of its about 200-2000 J is small, and the pulse is short-lived. The device provides an opportunity at relatively low cost to get positive results, significantly improve the safety conditions and reliability of work, as the declared device allows you to work sustainably on safe modes and as a result arranged drill-injecting piles of increased carrier capacity. The developed electric pulse plant (EIU) is widely used in the device of drills. It is especially effective for the case of geotechnical construction in cramped conditions [1-9] (Figure 1).

With the help of eiu, it is possible to create a drilling-injecting joint-ERT of increased carrier capacity Fd.

“F” (F.d 1- 2).

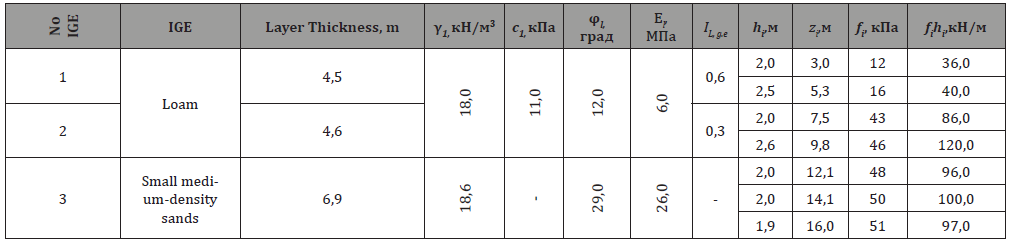

The definition of the carrying capacity of piles with multi-local debris differs from existing ones (regardless of pile types). СП 24.13330-2011Fd

According to the proposed method, the carrying capacity of piles with several “pullers” is implemented sequentially.

First, the side surface of the piles above the first “under-theback” is turned on, then the supporting ability of the base of the “push” is realized. Then the side surface on the next “backfill” which is immediately included in the work, etc. up to the very last “backfill.”

Here is an algorithm for determining the carrying ability of the piles-ERT with multi-local ears.

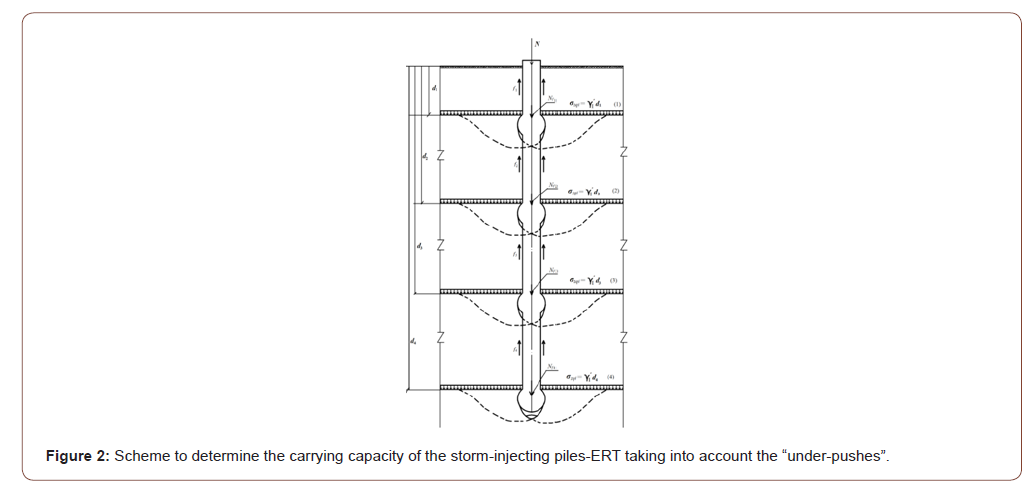

The engineering and geological section determines the length of the piles, marks for the device of “under-jackets” and the diameters of the expansions ku Ä (Figure 2, Table 1).

Table:Length of piles.

2. The carrying capacity of the piles-ERT on the side surface is calculated:

Conclusion

For the first time, the developed electric pulse plant is widely introduced into geotechnical practice in the construction of drills in pile fields, pit fences, ground anchors, as well as when cementing ground bases. Its use significantly facilitates work in geotechnical construction, as well as expands the development opportunities previously considered unsuitable for construction.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Invention patent #N2250958. The device for manufacture of a stuffed pile. Authors: Sokolov NS, Tavrin VYu, Abramushkin VA (2005) Federal Service for Intellectual Property and to trademarks. Bulletin of inventions 12: 3.

- Invention patent #N2282936. The generator of impulse currents. Authors: Sokolov НС, Pichugin YP (2006) Federal Service for Intellectual Property and Trademarks. Bulletin of Inventions 24: 6.

- Sokolov NS, Ryabinov VМ (2015) About one method of calculating the load-bearing capacity of flight augering pile –EDT. "Bases of foundations and soil mechanics" 1: 10-13.

- Sokolov NS, Ryabinov VМ (2016) About the effectiveness of the device flight augering piles with multi-site broadenings using electric discharge technology. Geotechnics 2: 28-34.

- Sokolov NS (2014) Method of calculating the load-bearing capacity of flight augering pile -IDT, taking into account "thrust bearing". New in architecture, design of building structures and reconstruction: materials of VIII All-Russian (II International) conference NASKR-2014 Cheboksary: Publishing house Chuvash State University pp. 407-411.

- Sokolov NS, Sokolov SN, Sokolov AN (2017) Fine-grained concrete, as a structural construction material for flight augering piles –EDT. Building Materials pp. 16-20.

- Sokolov NS, Viktorova SS, Smirnova GM, Fedoseeva IP(2017) Flight augering piles -EDT as a buried reinforced concrete structure. Building materials.

- Razievich DV (1976) Technique of high stresses. 2nd ed: Energia p.69.

- F Fryungel (1965) Impulse technique. Generation and application of discharges condensers M – L Energy p.488.

-

Nikolay Sokolov. Electroimpulse Device for Manufacture of Continuous Flight Augering Piles. Cur Trends Civil & Struct Eng. 6(1): 2020. CTCSE.MS.ID.000630.

-

Concrete, Cylindrical specimens, Splitting test, Schmid rebound hammer, Elastic modulus, Compressive strength

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.