Mini Review

Mini Review

Drilled Piles Ert as Reinforcement of Bases of Increased Bearing Capacity

Sokolov NS, Chuvash State University, Russia.

Received Date: May 06, 2022; Published Date: May 23, 2022

Abstract

The construction of foundations with increased bearing capacity values is an urgent task of modern geotechnical construction. As a rule, deep drill piles with large diameters are used as a basis for such foundations. There are many technologies for their manufacture. Increasing their bearing capacity is possible only by changing their length and diameter. The use of drill-injection piles manufactured by electric discharge technology (piles- ERT) with multi-seat widenings solves the problem of creating foundations of increased bearing capacity.

Keywords: Brown-injection piles; ERT piles; Multi-seat widening; Bored piles; Bearing capacity; Engineering and geological conditions

Introduction

Drill piles in modern geotechnical construction are the main buried structures. They are in demand both in pile fields and in strengthening the foundations of foundations and are also used as sheet walls of pit fences. The problem of increasing the bearing capacity of these piles remains very urgent. For this, two approaches are possible. In the first way, increased values are increased Fd can only be achieved by increasing the diameter and length of the drill piles. Particular attention should be paid to the fact that an excessive increase in drilling diameters will lead to the restructuring and compaction of the soil of the walls of wells, which will attract a change in the stress-strain state (VAT) of the base that has developed over a long geological period. At the same time, the return of the decompacted state to the original only due to the own weight of the concrete laid in the well is not possible. The second way to increase the Fd drill piles is by extending under the heel and along the shaft of the piles. According to this method, there are large reserves in terms of a significant increase in their bearing capacity. When creating widenings of the trunk and heel of the pile, there is a multiple increase in its bearing capacity on the ground. The practice of designing, manufacturing, and operating such piles has shown their high efficiency. Including very serious laboratory and field research in this regard were carried out by specialists of the laboratory of foundations and foundations of the Ural Institute “Promstroyinvestrproekt” under the leadership of A.N. Tetiora [6]. According to the results of field tests with static loads, the bearing capacity of a pile with one and with two widenings was greater than the bearing capacity of the same pile without widenings by 1.5-2.0 and 3.0-4.0 times, respectively. At the same time, there are disadvantages of mechanical widening. This is, firstly, as in bored piles, the decompaction of the soil, both the walls and in the area of the widening device. Secondly, in sandy soils it is almost impossible to arrange widenings due to their crumbling on the bearing layer of the sole. In particular, it is not possible to accurately determine the marks of the widening device due to the complexity of the engineering and geological conditions (ISU) of the construction site. The most acceptable geotechnical technology for increasing Fd by the second method is the device of widening by electric discharge technology.

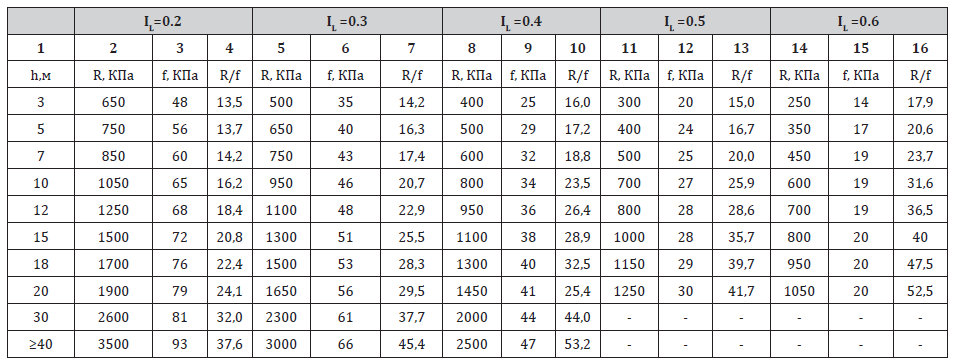

The author of this article (LLC NPF “FORST”)) for a long time is engaged in the design and installation of ERT piles. They showed that ERT piles with multi-seat widenings (SMEs) have an increased bearing capacity compared to piles without widenings. Pressure testing of the walls of the well using ERT technology is carried out using camouflage extensions [5-10, 13]. These are drill injection piles arranged using discharge-pulse technology (piles-ERT). These piles have increased values YCR YCF , namely YCR = 1.3, and YCF = 1.1÷1.3 due to the restoration of the soil structure of the walls of the wells, and in most cases - its compaction beyond natural values. Thus, the increase in bearing capacity under the lower end of the pile-ERT is 1.3 times, and on the lateral surface – B 1.1/0.5 ÷ 1.3/0.5 = 2.2÷2.6 times. When determining the bearing capacity of Fd according to the formula (7.11) [11], the values of the calculated resistances R and f are determined from Tables 7.3 and 7.8. [11]. In Table. 7.3 [11] shows the values f for different values of IL and f, and in Table 7.8 [11] - the same for R. For clarity of the value R/ f = f (h) for different values of IL is listed below in Table 1 and figure 1 (Table 1, Figure 1).

Table 1:Resource requirements by component Dependencies R/f =f(h) for different values of IL.

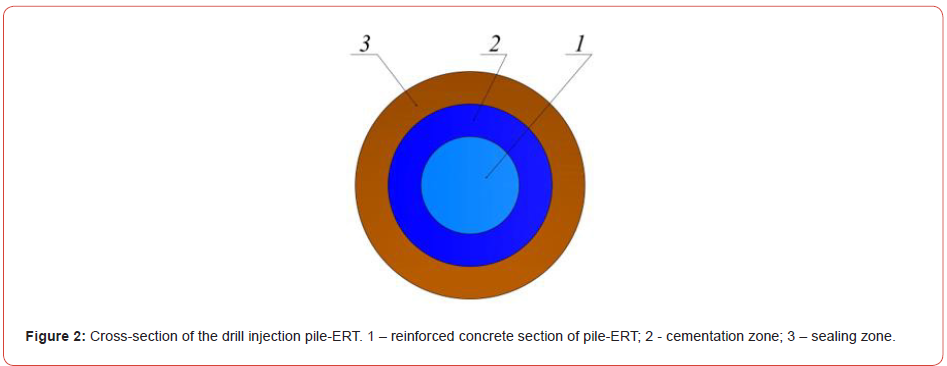

Unlike bored piles, unlike bored piles, have the main advantage. This is the ability to seal the compacted walls of boreholes by means of electrohydraulic treatment in an environment of fine-grained concrete in excess of natural. As a result of this process, in the cross section of piles-ERT, in addition to the reinforced concrete section of piles (Figure 1), the following are created: 1) cementation zone; 2) sealing zone (see Figure 2). In this case, the cementation zone tends to increase over time (Figure 2).

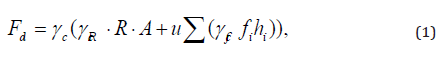

Determination of bearing capacity Fd is made according to the formula (7.11) [11]

where γc is the coefficient of the working conditions of the pile in the ground, taken to be equal to 1; R is the calculated resistance of the soil under the lower end of the pile, kPa (Tc/m2), taken according to Table. 7.2 [11]; A - area of support of the pile on the ground, m; u - the outer perimeter of the cross-section of the pile, m; fi is the calculated resistance of the i-th layer of the base soil on the side surface of the pile, kPa (tf/m2), taken according to Table. 7.3 [11]; hi is the thickness of the i-th layer of soil in contact with the side surface of the pile, m; γcf is the coefficient of working conditions of the soil, respectively, by the lower end and on the side surface of the pile, taking into account the influence of the method of immersion of the pile on the values of the calculated resistance of the soil and taken according to Table. 7.6 [11]; γcR is the coefficient of working conditions under the lower end of the pile according to clause 7.26 [11].

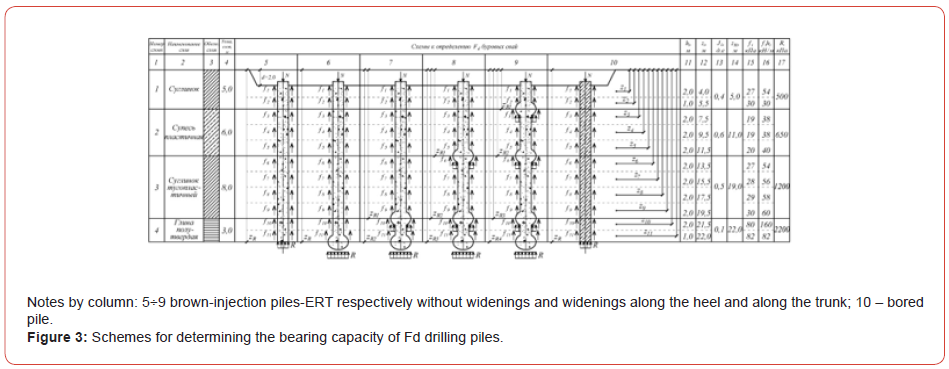

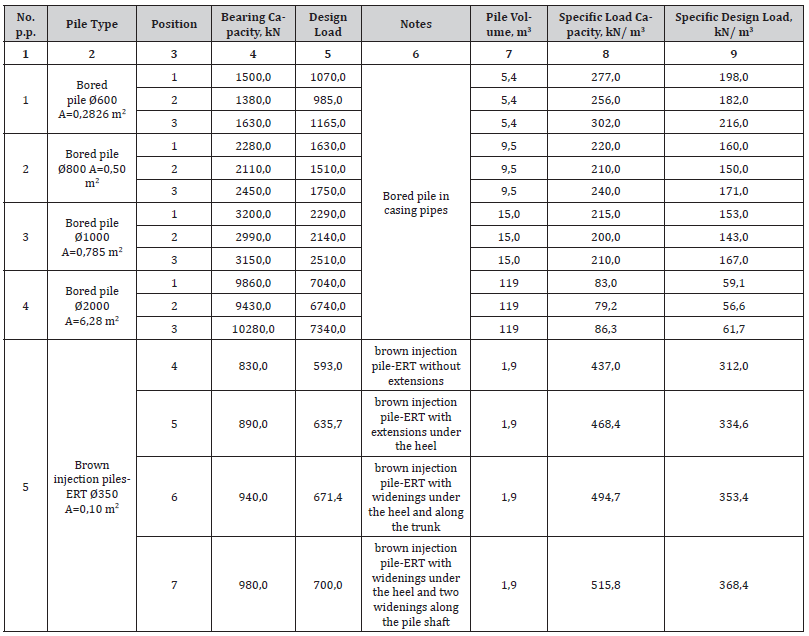

According to the formula (1), calculations of the bearing capacity of Fd on the soil of various types of drill piles cutting through tightplastic loam with IL = 0 are made. 4, plastic loam with IL = 0.6, tight loam with IL = 0. 5, and semi-solid clay with IL = 0. 1. The heel of the piles is sealed in semi-hard clay. As types of drill piles, the following are used: 1) brown injection piles-ERT without widenings and with widenings under the heel and along the shaft; 2) bored piles Ø 600, 800, 1000 mm, recyclable in casing pipes, under the protection of thixotron clay, as well as laid by deep vibration. Schemes for the calculation of Fd are given in Figure 3, and the results of calculations are summarized in Table 2 (Table 2, Figure 3).

Table 2:

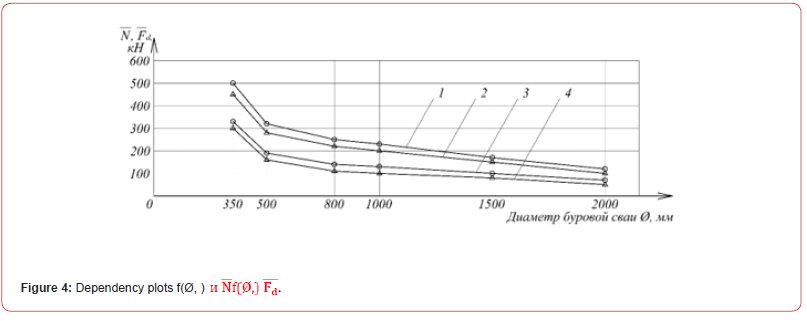

For a comparative assessment of the values of the bearing capacity of piles and the design loads on them in Table 1 there are values of their specific values, this is the specific bearing capacity of the corresponding and specific design load corresponding to, where is the volume of the pile under consideration.

Here is the specific load capacity [kN], is the specific design load [kN]; 1 and 2 – graphs f(Ø,); 3 and 4 – graphs f(Ø, ), Ø – pile diameter.

The most characteristic graphs of dependence on the diameter and type of piles are shown in Figure 4. The predominance of piles- ERT reaching up to 5 times these values for bored piles is clearly traced. At the same time, with an increase in the diameter of the piles, the graphs acquire a linear falling character.

Acknowledgment

None.

Conflict of Interest

None.

Conflict of Interest

No conflict of interest.

References

- Ilyichev VA, Mangushev RA, Nikiforova NS (2012) Experience in the development of the underground space of Russian megacities. Foundations, foundations and mechanics of soils, 2: 17-20.

- Ulitskiy VM, Shashkin AG, Shashkin KG (2010) Geotechnical support of urban development. SPb.: Geo re-construction, p.551.

- Ter-Martirosyan ZG (2009) Mechanics of soils. M.: ASV. P.550.

- Ukhov SB (2007) Mechanics of soils, foundations, and foundations. M.: Vysshaya shkola, P.561.

- Ulitskiy VM, Shashkin AG, Shashkin KG (2012) Geotechnics Guide (a guide to foundations, foundations, and underground structures). Second edition, additional. Saint Petersburg. P.284.

- Sokolov NS, Sokolov SN (2005) The use of brown injection piles in the fixation of slopes. Materials of the Fifth All-Russian Conference "New in Architecture, Design of Building Structures and Reconstruction" (NASKR-2005), Cheboksary: Chuvash University Publishing House. pp.292-293.

- Sokolov NS (2014) Method of calculating the bearing capacity of drill injection piles-RIT taking into account "podpyatnikov". Materials of the 8th All-Russian (2nd International) conference "New in architecture, design of building structures and reconstruction" (NASKR-2014). Cheboksary: Chuvash State University Publishing House. pp.407-411.

- Sokolov NS, Ryabinov VM (2015) On one method of calculating the bearing capacity of brown injection piles-ERT. "OFiMG". 1: 10-13.

- Sokolov NS, Ryabinov VM (2016) On the efficiency of the device of drill injection piles with multi-seat widenings using electric discharge technology. Geotechnics, 2: 28-34.

- Sokolov NS, Ryabinov VM (2016) Features of the device and calculation of drilling piles with many-seated widening. Geotechnica, 3: 60-66.

- Sokolov NS, Ryabinov VM (2016) Technology for the production of bored injection piles in an elevated quarry. Residential construction. 9: 11-14.

- SP 24.13330. (2011) 2011 Updated edition of SNiP 2.02.03-85 Pile foundations. P.85.

- TR 50-180-06 (2006) Technical recommendations for the design and installation of pile foundations performed using discharge-pulse technology for high-rise buildings (piles-RIT). Department of Urban Planning Policy, Development and Reconstruction of the City of Moscow. P.68.

- Gorbushin AV, Ryabinov VM (2016) Possibility of using electro-discharge technology in construction in non-weak soils. OFiMG, p.10-13.

-

Sokolov NS. Drilled Piles Ert as Reinforcement of Bases of Increased Bearing Capacity. Cur Trends Civil & Struct Eng. 8(5): 2022. CTCSE.MS.ID.000696. DOI: 10.33552/CTCSE.2022.08.000696.

-

Brown-injection piles, ERT piles, Multi-seat widening, Bored piles, Bearing capacity, Engineering and geological conditions

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.