Mini Review

Mini Review

Compaction and Strength Behaviour of an Expansive Clay Modified by Lime and Quarry Dust

BR Phanikumar*, M Jagapathi Raju and E Ramanjaneya Raju

Department of Civil Engineering, SRKR Engineering College, India

BR Phanikumar, Department of Civil Engineering, SRKR Engineering College, Bhimavaram, India.

Received Date: October 14, 2019; Published Date: October 29, 2019

Abstract

Expansive soils have a tendency to undergo volumetric changes corresponding to changes in water content. As a result, civil engineering structures founded in these soils are severely distressed. This has caused a huge financial loss, it is, therefore, necessary to reduce volumetric changes of these soils by physical and chemical alteration. This paper presents experimental results on a remolded expansive clay blended with varied amounts of quarry dust and lime. Compaction characteristics, stress-strain characteristics, unconfined compressive strength (UCS) were studied.

Keywords: Expansive soils; Physical alteration; Chemical alteration; Quarry dust and lime

Introduction

Introduction

Expansive soils are highly problematic because of their tendency to undergo risky volumetric changes consequent upon changes in water content [1]. These volumetric changes happen in alternate seasons of winters and summers. These alternate swelling or volume increase and shrinkage or volume reduction cause damage to lightly loaded structures founded in them such as foundations, retaining walls, pavements, airports, sidewalks, canal beds and linings [1,2]. To address the problems posed by expansive soils, various innovative foundation practices have been devised which can be broadly classified as (i) avoiding expansive material, (ii) mechanical, physical or chemical alteration and (iii) adopting special foundation techniques. In physical alteration technique, granular material is mixed with expansive clay to minimize heave [3-5]. In chemical alteration, addition of chemicals to expansive clay alters the nature of clay minerals thereby reducing heave. Of all chemicals tried, lime has been found to be most effective and economical additive. This paper presents an experimental work on a remolded expansive clay blended with quarry dust (QD) and lime in varied amounts. The effect of quarry dust and lime on the compaction characteristics and stress-strain behavior was studied. The values of unconfined compressive strength (UCS) were reported.

Experimental Investigation

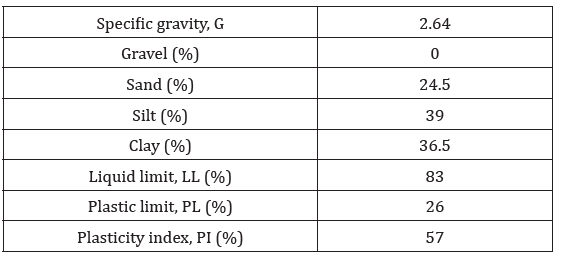

A remoulded expansive clay of free swell index (FSI) 120% was used in testing. Table 1 shows the index properties of the clay. Further, quarry dust and lime were also used as blend materials. Quarry dust was varied as 0%, 5%, 10%, 15%, 20%, 25% and 30% by dry weight of the soil; and lime was varied as 0%, 1%, 2%, 4% and 6%, it may be mentioned here that lime was added in different quantities to the blend of expansive soil and 30% quarry dust gave the highest MDD. The tests conducted were standard Proctor compaction tests and the unconfined compression tests. The standard proctor compaction tests on the unblended expansive clay and the clay blended with quarry dust and lime were performed accordingly to ASTM 2000 D698 a. The unconfined compressive strength tests were performed on the unblended clay and the clay blended with quarry dust and lime were performed accordingly to ASTM 2000, D2166 on cylindrical samples of length 76mm and Diameter 38mm. The effect of curing period on UCS were also studied (Table 1).

Table 1: Index Properties and Compaction characteristics of the expansive clay.

Results and Discussion

Effect of quarry dust and lime on compaction characteristics

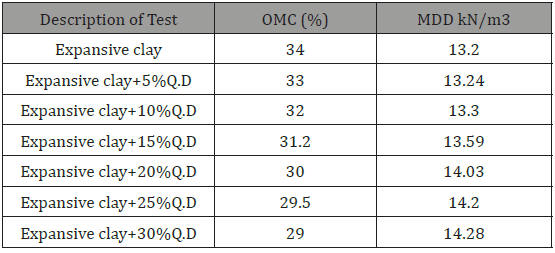

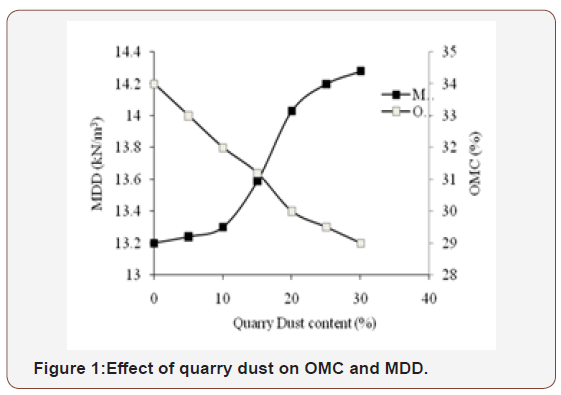

Table 2 shows the effect of quarry dust on the compaction characteristics of the expansive clay. The OMC and MDD of the unblended expansive clay were 34% and 13.2 kN/m3 respectively. However, when quarry dust was added to the expansive clay in increased amounts, the MDD increased and OMC decreased. MDD increased from 13.2 kN/m3 to 14.28 kN/m3 when QD increased from 0% to 30%; and OMC decreased from 34% to 29%, when quarry dust content increased from 0% to 30%. This clearly showed that quarry dust is a good stabilizer of expansive clays. Figure 1 shows the variation of OMC and MDD with quarry dust content (Table 2) (Figure 1).

Table 2: Effect of quarry dust on compaction characteristics of expansive soil.

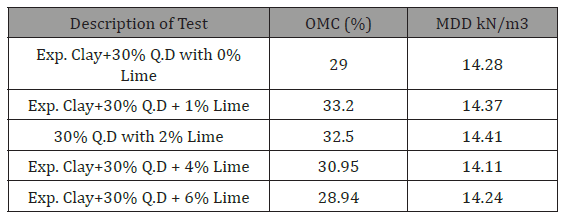

Table 3 sows the effect of lime on OMC and MDD of the expansive clay blended with 30% quarry dust. The data show that MDD slightly increased up to 2% lime and thereafter slightly decreased (Table 3).

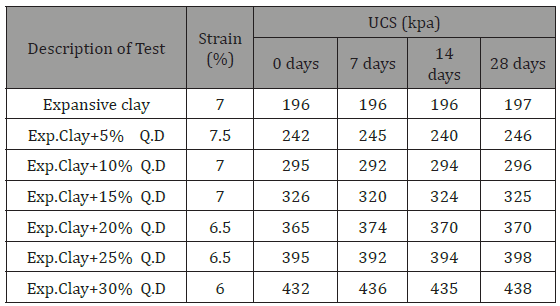

Table 4 shows the effect of quarry dust on unconfined compressive strength of the expansive clay. As quarry dust content increased, the UCS increased. For example, the UCS increased from 196 kPa to 432 kPa, when the quarry dust content increased from 0% to 30%. However, it should be mentioned that there was no effect of curing period on the UCS of clay-blended with quarry dust alone (Table 4).

Table 3: Effect of Quarry dust and lime on compaction characteristics of expansive soil.

Table 4: Effect of quarry dust on unconfined compressive strength of expansive soil.

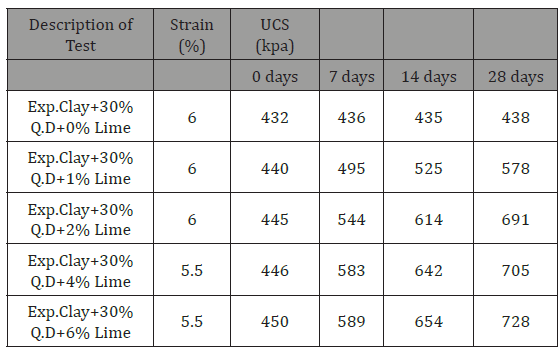

Table 5: Effect of quarry dust and lime on unconfined compressive strength of expansive soil.

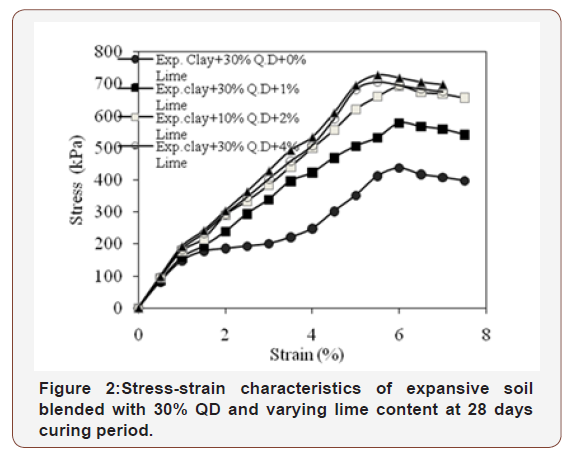

Table 5 shows the UCS of the expansive clay blended with 30% quarry dust and varied amounts of lime. When lime was added to the blend of clay and 30% quarry dust, the UCS increased significantly. For example, the 28-day UCS increased from 438 kPa to 728 kPa when the lime content is increased from 0% to 6%. Figure 2 shows the stress-strain characteristics of 28-day specimens blended with 30% quarry dust and varied amounts of lime (Table 5) (Figure 2).

Conclusion

MDD increased and OMC decreased when quarry dust was added to the expansive clay in increased amounts. When lime was added to clay-quarry dust blend, MDD further increased but only up to 2% lime. In the samples of clay blended with quarry dust alone, UCS increased with increasing quarry dust content. But, there was no effect of curing period on UCS. However, in the clay-quarry blends to which lime was added, there was a significant effect of curing period apart from that of lime.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Chen FH (1988) Foundations on expansive soils. Elsevier Scientific Publishing Co, Amsterdam, USA.

- Nelson DJ, Miller JD (1992) Expansive Soils: Problems and Practice in Foundation and Pavement Engineering. Wiley, New York.

- Phanikumar BR, Sharma RS, Rao AS, Madhav MR (2004) Granular Pile-Anchor Foundation System for Improving the Engineering Behaviour of Expansive Clay Beds. Geotechnical Testing Journal, ASTM 27(3): 279-287.

- Ranganatham BV, Sathyanarayana B (1965) A rational method of predicting swelling potential for compacted expansive clays. Proc 6th Int Conf SM & FE, Canada, 1: 92-96.

- Satyanarayana B (1966) Swelling pressure and related mechanical properties of black cotton soils. PhD thesis submitted to Indian Institute of Science, Bangalore, India.

-

BR Phanikumar, M Jagapathi Raju, E Ramanjaneya Raju . Compaction and Strength Behaviour of an Expansive Clay Modified by Lime and Quarry Dust. Cur Trends Civil & Struct Eng. 4(1): 2019. CTCSE.MS.ID.000582.

-

Expansive soils, Physical alteration, Chemical alteration, Quarry dust and lime, water content, Free swell index, Compressive strength

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.