Research Article

Research Article

An Experimental Investigation of Carbon Fiber Plates Used for High Strength Reinforced Concrete Beams

Osama K Adwan*, Brahim M Bousalem and Abbas M Al Shahary

Department of Civil Engineering, Al -Baha University, Saudi Arabia

Osama K Adwan, Department of Civil Engineering, Al -Baha University, Saudi Arabia.

Received Date: January 27, 2020; Published Date: February 11, 2020

Abstract

Carbon fiber plates (CFPs) have been used sufficiently to strengthen reinforced concrete structures and is becoming an increasing familiar approach amongst structural engineers. In this research investigation, four-point bending flexural tests were carried out to four full-size High Strength Reinforced Concrete (HSRC) beams without CFPs and four full-size HSRC beams strengthened with CFPs. All beams were subjected to short term static loads. The experimental test results presented herein showed that the use of CFPs had remarkable effects on the ultimate carrying capacity and the structural behaviour of all beams tested. In addition, the stiffness of RC beams strengthened with CFPs have increased significantly.

Keywords: Composite structure; High strength concrete beams; Ultimate load capacity; Load-deflection relationship; Stiffness and carbon fiber plates

Introduction

The use of Carbon Fibre Polymer (CFPs) laminates is one of repair and/or strengthening methods with clear and many advantages over other techniques such as light weight, corrosion resistance, good durability and physical performance stability [1- 3]. In addition, in terms of its use in the construction industry; it has many advantages such as quick operation, wide applications, and other advantages [4]. Therefore, the use of CFRP in concrete structures can be widely applied in the field of bridge engineering reinforcement [5,6]. Concrete structures strengthened by CFPs are not only convenient, but also low cost which one of the effective methods of strengthening technology [7]. Indeed, it can be effectively extended to practical engineering. Currently, according to the authors best knowledge no or limited research investigations relating to the structural behaviour and performance of high strength reinforced (HSR) concrete structures made with CFPs are available. Therefore, the main objectives of this investigation are to provide and highlights some information and behaviour of such beams specifically the ultimate load capacity and load-deflection behaviour of HSR concrete beams strengthened by CFPs.

Test Methodology

Beam test specimens

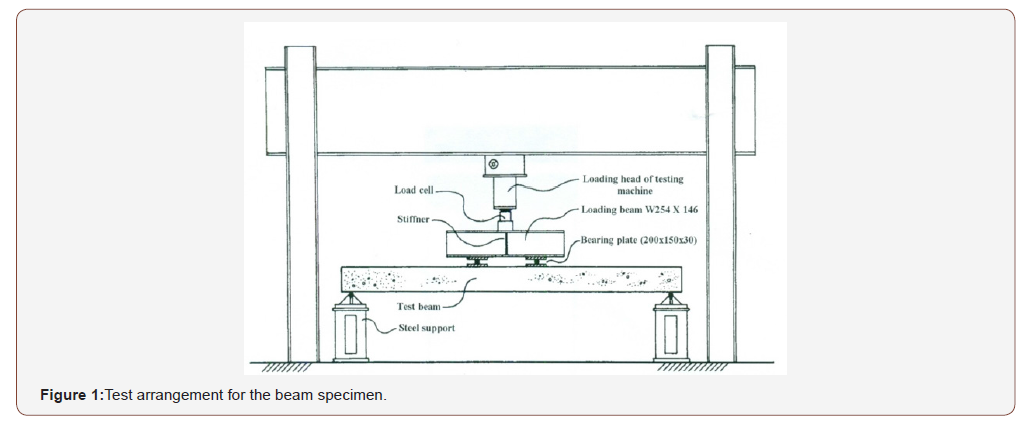

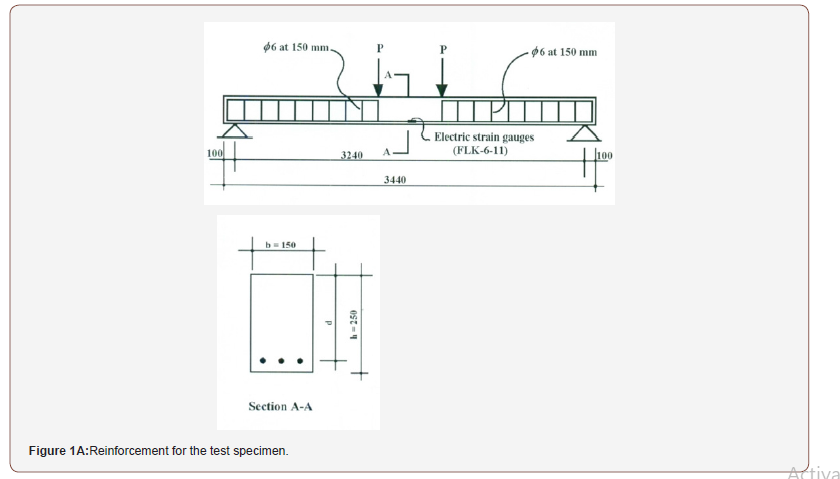

The concrete compressive strength was in the range of 100 MPa. The choice of the size and the length of test specimens was made in order to make the beam fail in flexure (a/d= 6), and to ensure that the specimen be sufficiently large to simulate a real structural element. With these considerations in mind, a specimen with a cross-section of 150 x 250 mm and span length of 3240 mm was chosen. Figures 1 and 1A illustrate testing arrangement and reinforcement details for beam specimens. High yield deformed steel bars of 12 mm and 20 mm diameters were used.

Loading procedures and instrumentation

A total of eight RC beams were cast; four full-size HSRC beams without CFPs and four full-size HSRC beams strengthened with CFPs. The design and construction of the beams were in accordance with BS 8110 and BS 5328. All the tests in this investigation were performed using the static screw-head jack as shown in Figure 1, through a single point, transferred to the concrete member through a universal steel spreader beam, i.e., W 254 x 146 with a total length of 1200 mm, designed and fabricated for the test purpose. The steel spreader beam was supported on two bearing plates 200 x 150 x 30 mm resting on steel rollers, covering the entire width of the beam, and placed symmetrically with respect to the mid-span section at a distance of 600 mm. The applied load was measured by a load cell of a maximum capacity of 1000 kN connected to a data logger. LVDT was also used to measure the vertical deflection of the beams at different load intervals. All CFPs beams were prepared by grit blasting the beam soffit and then blowing to ensure clean surfaces. The plate was then cleaned thoroughly with solvent. Sikadur 30 two-part epoxy adhesive was applied to both the plate and the beam soffit to a thickness of 1 mm. The plate was then carefully placed on the beam soffit to ensure to be in central of the beam edges. Pressure applied with a hand roller to ensure an even distribution of the adhesive and a sufficient bond (Figure 1, Figure 1A).

Experimental Results, Analysis and Discussion

Ultimate carrying load capacity

For all R.C beams tested, the ultimate carrying loads are recorded for HSR beams without CFPs and R.C beams strengthened by CPPs respectively – See Table 1. It has been noticed that the ultimate loads of all beams which were strengthened by CFPs increased significantly i.e., the ultimate load of HSRC1-1 increased by 32%, the ultimate load of beam HSRC2-1 improved by about 33%, 39% for HSRC3-1 beam and 32% for HSR4-1 beam respectively. Therefore, it can be stated that applying CFPs at the bottom surface of the reinforced concrete beams has remarkable effect on improving the ultimate capacity of all beams tested.

Load-deflection analysis

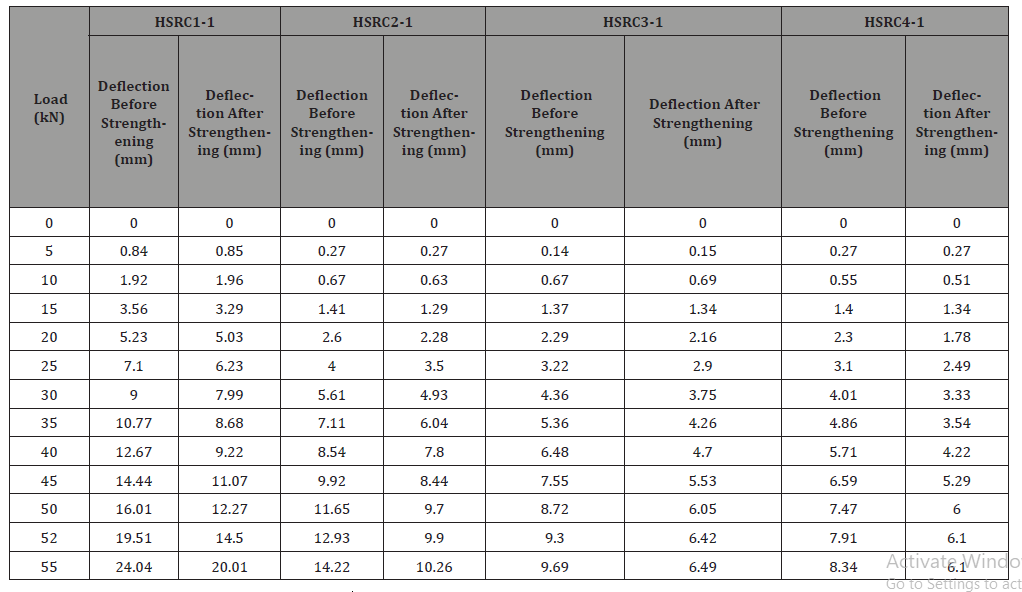

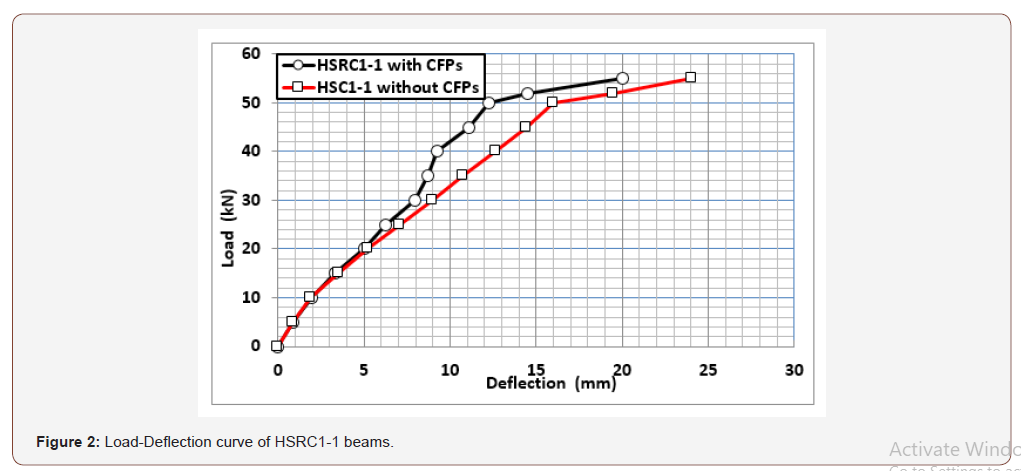

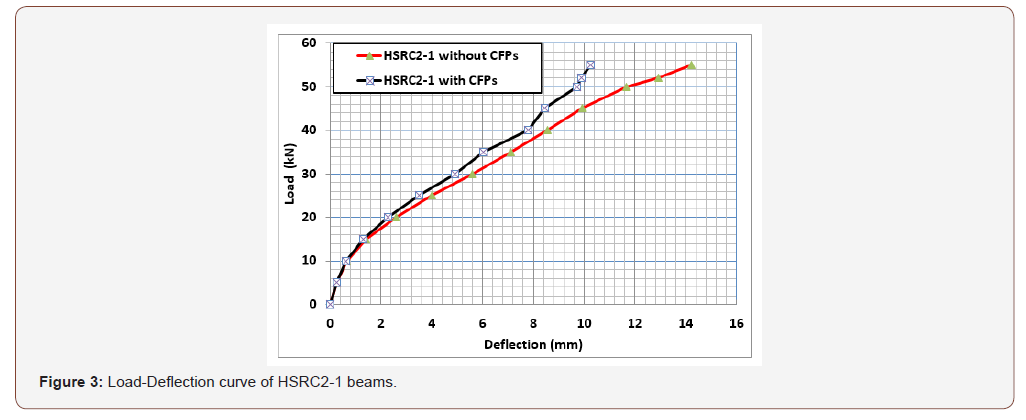

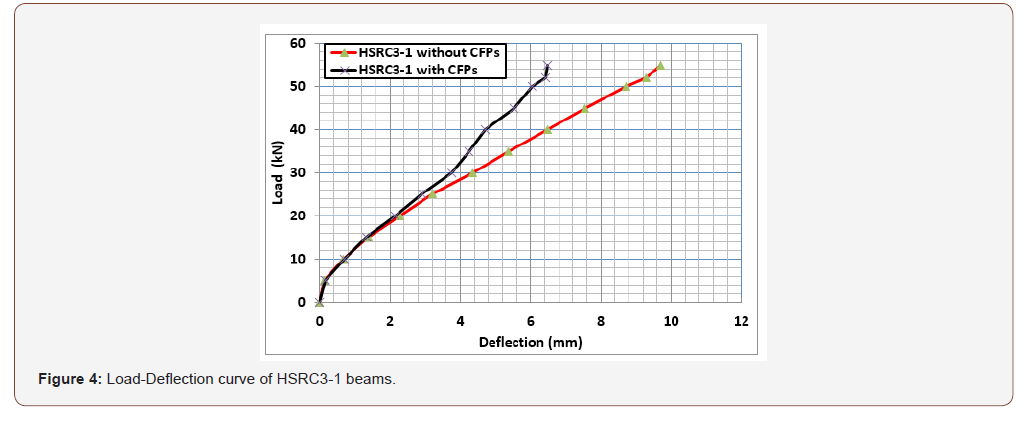

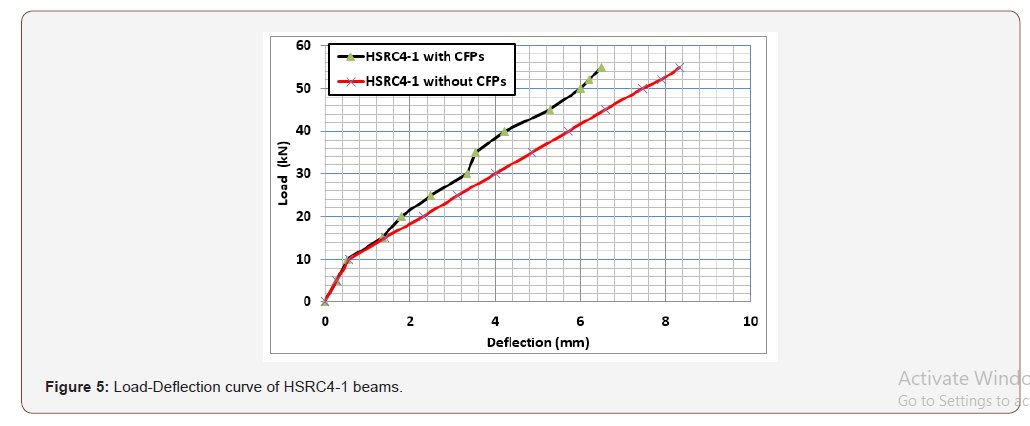

For all R.C beams tested the mid-span deflection was measured at each load increment. All test load-deflection data are shown in Table 3. These data were analysed and represented in Figure 2 to Figure 5. It can be stated, that at the initial loading the deflections for reinforced beams without CFPs and reinforced beams strengthened by CFPs are more or less the same. Furthermore, when the load increases the mid-span deflection of R.C beams without CFPs increased significantly whereas for R.C beams with CFPs increased slowly. The deflection of HSRC1-1 beam without CFPs was 20% much higher when compared with HSCR1-1 beam with CFPs. This phenomenon was also observed for all R.C beams tested- See Figures 2 to 5. Overall, it can be concluded that, employing CFPs in R.C beams can effectively increase the stiffness (Table 1).

Table: 1Carrying ultimate load capacity test results.

Table: 2Displacement ductility index.

Table: 3Load-Deflection experimental results at mid-span for all reinforced concrete beams.

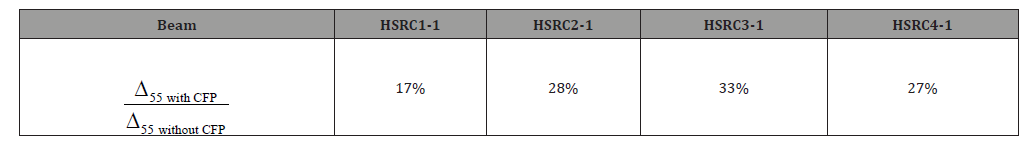

Displacement Ductility Index μ_Δ55

Table 1 reflects that from the experimental study there is a significant effect of CFP on the flexural capacity of the beams. Table 2 represents the displacement ductility index for all beams tested. It can be stated that beams strengthened with CFP produces lower deflection and hence lower ductility. The decrease in ductility varies from 17 % for beam HSRC1-1 to 33% for beam HSRC3-1 (Tables 2,3)(Figures 2-5).

Conclusion

In this research study, eight concrete beams were constructed and tested. Four full-size High Strength Reinforced Concrete (HSRC) beams without CFPs and four full-size HSRC beams strengthened with CFPs. The structural behaviors of the beams were evaluated by four-point bending tests. The ultimate carrying loads capacity and load-defections were measured. Based on the results of this investigation presented herein and in view of the experimental evaluations and analytical considerations the following conclusions can be drawn:

1. CFPs can significantly improve the ultimate flexural capacity of structures and can also improve the bending stiffness of the structure. Thus, enhance the integrity of the structure.

2. The mid-span deflections for reinforced concrete breams strengthened with CFPs were effectively suppressed when compared with normal reinforced concrete beams.

3. Beams strengthened with CFP produces lower deflection and hence lower ductility.

4. It is worth to note that, as an exploratory study, only a limited number of test specimens were investigated in this study. Further study is recommended to draw more solid conclusions.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Kim I, Jirsa JO, Bayrak O (2013) Anchorage of carbon fiber-reinforced polymer on side faces of reinforced concrete beams to provide continuity. ACI Structural Journal 110(6): 1089.

- Kim C, Ghannoum WM, Jirsa JO (2016) Behavior of reinforced concrete panels strengthened with carbon fiber-reinforced polymers. ACI Structural Journal 113(5): 1077.

- Ganga Rao HV , Vijay P (1998) Bending behavior of concrete beams wrapped with carbon fabric. Journal of structural engineering 124(1): 3-10.

- Rafi MM, Ali N, Faris A, Didier T (2008) Aspects of behaviour of CFRP reinforced concrete beams in bending. Construction and Building Materials 22(3): 277-285.

- Parrott L (1988) A literature review of high strength concrete properties. British Cement Association Camberley.

- Xu L, Yu X, Di ZY (2014) Experimental study of CFRP reinforced concrete beams. in Applied Mechanics and Materials. Trans Tech Publ pp.1271-1275.

- Adwan O, Maraqa F (2001) Failure Mechanism of Carbon Fibre Reinforced Plastic used for Reinforced Concrete Structures, in 7th International Conference on Inspection, Appraisal, Repairs and Maintenance of Buildings and structures. 2001: Nottingham, United Kingdom p. 163-170.

-

Osama K A, Brahim M B, Abbas M A S. An Experimental Investigation of Carbon Fiber Plates Used for High Strength Reinforced Page 5 of 5 Concrete Beams. Cur Trends Civil & Struct Eng. 5(1): 2020. CTCSE.MS.ID.000603.

-

Composite structure, High strength concrete beams, Ultimate load capacity, Load-deflection relationship, Stiffness and carbon fiber plates

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.