Mini Review Article

Mini Review Article

The Use of Electric Discharge Technology in Strengthening the Base of the Reconstructed Object

Sokolov NS, Chuvash State University, Russia.

Received Date:July 25, 2023; Published Date:July 31, 2023

Abstract

Reconstruction of buildings and structures in cramped conditions is a complex technological task associated with ensuring the safe operation of buildings of the surrounding development in areas of geotechnical influence and reliable operation of foundation bases using buried reinforced concrete structures, such as drilling piles performed using electric discharge technologies. The article considers the case of reconstruction of a public facility using electric discharge technology when strengthening the body of the foundations with the help of drilling piles EDT.

Keywords:Reconstruction; Loads; Zone of influence; Electric discharge technology; EDT Piles; Bearing capacity

Introduction

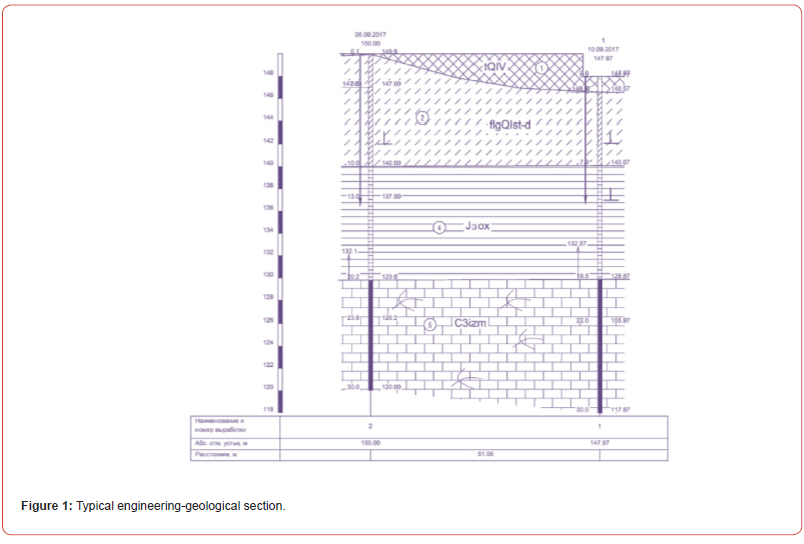

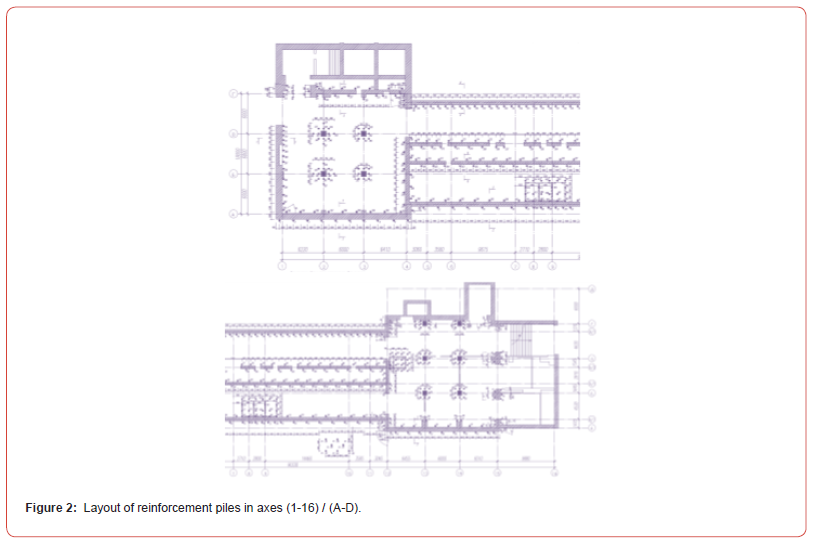

The reconstructed building consists of five blocks: Block No. 1 in the axes “1-4 + A-G”, dimensions in the axes 18.63x18.0 m, three-story, with a basement, a basement, and a technical attic. The structural system is an incomplete frame with reinforced concrete columns and crossbars with hinged support nodes for the crossbars, and external masonry walls. Ceilings - prefabricated reinforced concrete slabs. The foundation is a reinforced concrete slab. Block No. 2 in the axes “4-12÷A/1-B/1”, dimensions in the axes 42.855x15.16m, four-story, with a basement, a basement, and a technical attic. The structural system is a wall system with longitudinal load-bearing walls made of masonry. The ceilings are prefabricated reinforced concrete slabs. The foundation is a reinforced concrete slab. The covering of the attic and the ceiling of the fourth floor have been completely dismantled at the moment. Block No. 3 (Figure 2) in the axes “12-15÷A-K”, dimensions in the axes 18.965x48.46m. three-story, with a basement, a basement (partially, in the axes “A-E”) and a technical attic. Structural system - an incomplete frame with reinforced concrete columns and crossbars in the axes “A-E” and steel columns and beams in the axes “E-K” with hinged support nodes of the crossbars and beams, and external walls made of masonry. Ceilings - prefabricated reinforced concrete slabs. The foundation is a reinforced concrete slab in the axes “A-G” and a reinforced concrete tape in the axes “G-K”. Block No. 4 (Figure 2) in the axes “13/1-15÷K-L”, dimensions in the axes 11.32x15.62 m, four-story, with a basement and a technical attic. Structural system - wall with longitudinal load-bearing walls made of masonry, with steel floor beams, beam support nodes are hinged. Ceilings - above the basement - cylindrical vaults of solid ceramic bricks on metal beams, above the rest of the floors - prefabricated reinforced concrete slabs. The foundation is a strip of limestone masonry. Block No. 5 (Figure 2) in the axes “15-16÷A-K”, dimensions in the axes 9.88x48.46m; one-story, with a basement in the axes A-G, a basement floor in the axes A-K, an overground floor in the axes A-E. The structural system is an incomplete frame with stone columns and crossbars with hinged support nodes for the crossbars, and external masonry walls. Ceiling above the basement floor - prefabricated reinforced concrete slabs, covering - from asbestos-cement hollow slabs filled with mineral wool on metal beams. Foundation - reinforced concrete strip under the walls and free-standing columnar under the columns. During the reconstruction of the building in accordance with the architectural space-planning solutions, it was supposed to change the planning and structural scheme of the building and a significant increase in the loads on the foundations (Figures 1,2).

Geomorphologically, the site is located within the ancient alluvial terrace of the Klyazma-Yauza channel. The surface of the area for the period of surveys (1947-1990) was characterized by absolute marks of 149.80-151.35 m. According to the materials of the State Budgetary Institution “Mosgorgeotrest” for the period of surveying, the geological and lithological structure of the site to the depth of the drilled wells is presented as follows: from the surface to a depth of 1.3-4.5 m, the site is covered with technogenic soils (t-QIV), represented by sands, with the inclusion of building rubble, brick fragments, wood chips and slag, caked, wet. Under technogenic soils lie Upper Quaternary alluvial deposits (a-QIIIIK-J) are represented mainly by sands, less often by loams, peat interlayers are encountered in places. Sands are yellow and yellowish-gray, fine, medium-density, moist and water-saturated Loams are gray, silty, soft-plastic. Peat found in SLE. No. 14-3608 g/s directly under the embankment, heavily decomposed, water saturated. The thickness of alluvial deposits is 1.5-2.7m. In well No. 2, moraine loams (g-QIId) were found. Loams are brown, sandy, with thin layers of water-saturated sand, with inclusions of gravel and pebbles, soft-plastic, 1.0 m thick. In some places, moraine loams are eroded, and alluvial deposits are underlain by the fluvioglacial strata of the Oka-Dnieper horizon (f-QIIo-d), represented by sandy loams and sands: Sandy loams are dark brown and black, dusty, micaceous, plastic, fluid in places; Sands - yellow and brown, medium size, heterogeneous, with gravel and crushed stone of siliceous rocks, medium density, water-saturated. The total thickness of fluvioglacial deposits is 5.8-7.0m, the stripped thickness is 4.7-5.8m. Under the stratum of Quaternary deposits at a depth of 10.3-10.5 m (absolute elevation 140.85-139.98), deposits of the Upper Jurassic were found, represented by the Volgian (J3v) and Oxfordian (J3ox) stages. The deposits of the Volgian stage are represented by black, silty, micaceous sandy loams with interlayers of glauconite sand, semi-solid, 3.2 m thick. The deposits of the Oxfordian stage are represented by black, silty, micaceous clays with large phosphorites and inclusions of fauna fragments, 6.8-10.1 m thick. C3mse), Perkhurovskaya (C3pr), Neverovskaya (C3nvr), Ratmirovskaya (C3rt). The Carboniferous stratum is represented by fractured limestones, marls and marl clays, and dolomites. The exposed thickness of the Carboniferous deposits is 10.6-35.0 m. The hydrogeological conditions of the territory are characterized by the distribution of the over-Jurassic aquifer. As of the time of the given engineering and geological surveys in 1947-1990. underground waters of the Nadjursky aquifer were opened at a depth of 1.3-5.4 m, abs. elev. 144.88-148.50 m. Water-bearing rocks are alluvial and fluvioglacial sandy deposits. Upper clays serve as a water seal. Opened at a depth of 10.3-10.5 m (abs. Elev. 139.98- 140.85). Groundwater in the Carboniferous deposits is drained by the permanent pumping of the Metropolitan.

Engineering and geological processes and phenomena have

been identified on the territory of the reconstruction of the object:

1. Karst-suffusion hazard of the site: In accordance

with the “Map of danger of ancient karst forms and jointsuffusion

processes” at a scale of 1:10000, sheet G-5 (GUP

“Mosgorgeotrest”, IGE RAS, Moscow. 2012, 2nd edition), the

site is located in a potentially dangerous area in relation to

the possibility of manifestation of modern karst-suffusion

processes.

2. Flooding of the territory and landslide processes: In

accordance with the “Map of landslide phenomena and flooding

by groundwater in Moscow” Scale 1: 10000, sheet G-5 (GUP

“Mosgorgeotrest”, NPP “Georesurs”, 2011, 2nd edition), the

site is located on the border of a flooded area with a depth of

groundwater of 1-3 m and periodically flooded territory, from

the depths oh occurrence of groundwater 3-5 m. Landslide

processes and their manifestations are not marked.

3. Frost heaving and depth of seasonal freezing. In

accordance with clause 5.5.3. SP 22.13330.2011 Updated

version of SNiP 2.02.03-85 Pile foundations and taking into

account SP 131.13330.2017 “Construction climatology”, the

normative load of seasonal freezing of soils dfn in open areas is:

- for dusty and fine sands: dfn=1.3 m; - for medium, coarse and

gravelly sands: dfn=1.4 m; - for coarse sands: dfn=1.6 m. The

physical and mechanical characteristics of the soils are given

below in Table 1.

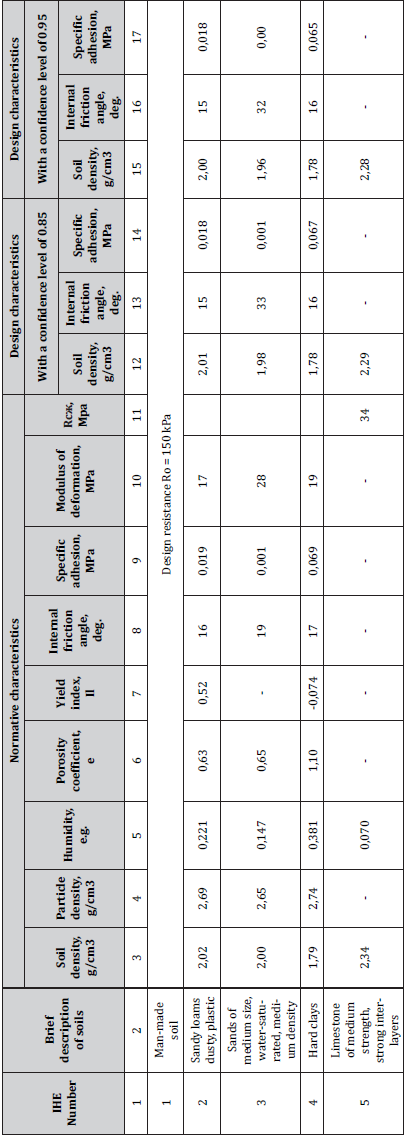

Table:Normative and design values of physical and mechanical properties of soils.

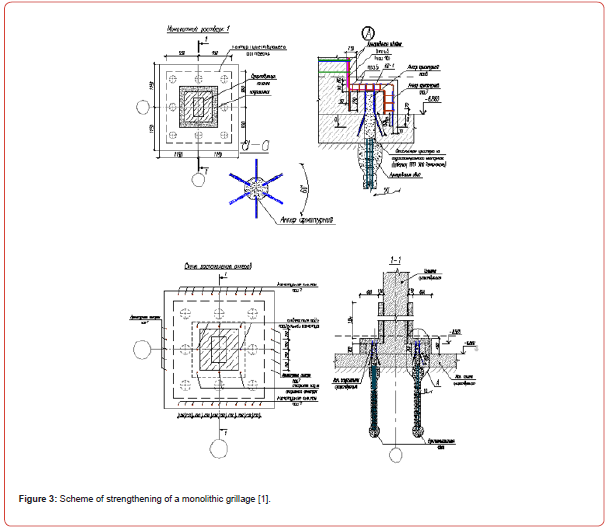

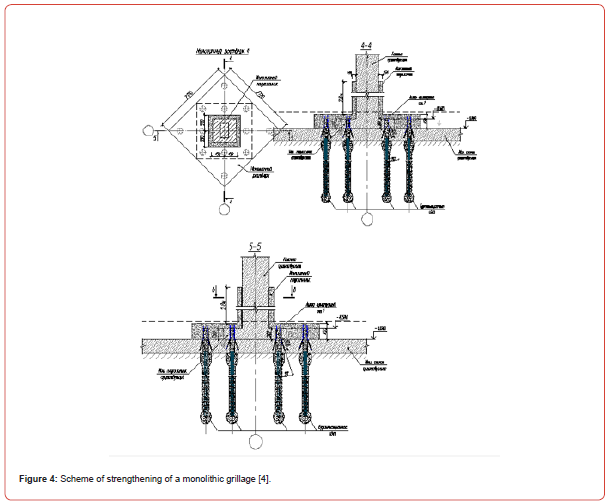

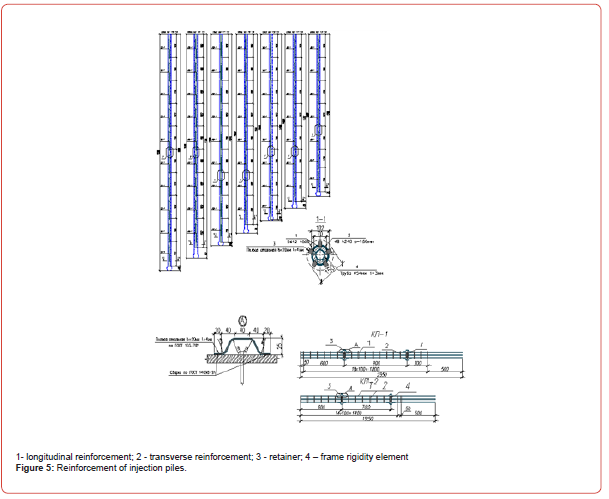

According to the reconstruction project, the structural scheme of the object was completely changed. If before the reconstruction the building was built in a frame, then after the reconstruction all external loads were perceived by the pile-slab foundation (see Figures 2, 3, 4). At the same time, in the supporting parts under the columns, additional steps were designed and arranged (Figures 3, 4) in order to avoid punching through the concrete of the foundation. In addition, anti-karst bored injection piles were designed and installed (Figures 3, 4).

Analyzing the experience of arranging bored piles at the object under consideration, bored injection piles were used, performed using electric discharge technologies - EDT piles. These piles have the maximum bearing capacity per 1 cubic meter of pile and are most in demand for work in cramped conditions [1-12].

Figures 2,3,4 show the EDT pile plan and characteristic sections. Depending on the loads and engineering-geological sections, EDT piles of different lengths were used in the plan - from 13.0 m to 17.0 m. Their reinforcement is shown in figure 5.

The entire technological chain for the production of EDT piles at a specific site is described below in the form of a technological regulation - an algorithm for the installation of EDT bored piles [11, 12].

Conclusion

The technology of arranging bored piles using electric discharge technologies is universal. It is widely used in both new construction and major repairs, as well as reconstruction of facilities. Technologically, all stages of the production of ERT piles are quite seriously developed. The whole complex of works is combined into a single technological regulation, which allows ensuring the high quality of the finished ERT pile at each cycle.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Ilyichev VA, Mangushev RA, Nikiforova NS (1985) Experience in the development of the underground space of Russian megacities pp. 17–20.

- Rodionov VN, Sizov IA, Tsvetkov VM (1986) Fundamentals of geomechanics. M Nedra, p.301.

- Ulitsky VM, Shashkin AG, Shashkin KG (2010) Geotechnical support of urban development. St. Petersburg: Georeconstruction p.551.

- Ter-Martirosyan ZG (2009) Soil mechanics M ASV p.550.

- Ukhov SB (2007) Mechanics of soils, foundations and foundations. M Higher school. P.561.

- Hassiotis S, Chamcau JL, Gunaratne M (1997) Design method for stabilization of slopes with piles. Journal of Geotechnical and Geoenvironmental Engineering 123 (4): 314-323.

- Lee JH, Salgado R (1999) Determination of pile base resistance in sands. Journal of Geotechnical and Geoenvironmental Engineering 125 (8): 673-683.

- Mandolini A, Russo G, Veggiani C (2005) Pile foundations: experimental investigations, analysis and design. Ground Engineering 38 (9): 34-38.

- Petrukhin VP (2003) Effect of geotechnical work on settlement of surrounding buildings at underground construction. In: VP Petrukhin, OA Shuljatjev, OA Mozgacheva (2003) Proceedings of the 13th European Conference on Soil Mechanics and Geotechnical Engineering. - Prague.

- Triantafyllidis Th (2007) Impact of diaphragm wall construction on the stress state in soft ground and serviceability of adjacent foundations. Th Triantafyllidis, R Schafer (2007) Proceedings of the 14th European Conference on Soil Mechanics and Geotechnical Engineering, Madrid, Spain, pp.683-688.

- Sokolov NS, Sokolov SN, Sokolov AN (2023) Inconsistencies in the reliable operation of the cultural heritage object - the Chuvash Drama Theater named after KV Ivanova. Housing construction. 4: 70-75.

- NS Sokolov, SN Sokolov, AN Sokolov, P Yu (2017) The use of ERT bored injection piles as bases for foundations of increased bearing capacity. Industrial and civil construction. 9(66).

-

Sokolov NS*. The Use of Electric Discharge Technology in Strengthening the Base of the Reconstructed Object. Cur Trends Civil & Struct Eng. 10(1): 2023. CTCSE.MS.ID.000730.

-

Reconstruction, Loads, Zone of influence, Electric discharge technology, EDT Piles, Bearing capacity

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

- Abstract

- Introduction

- Natural Geological Structure

- Evolution History of Landslide

- Development Characteristics of Jiangdingya Landslide

- Analysis of Catastrophe Mechanism of Landslides

- Stability Analysis of Landslide

- Safety Treatment of Landslide

- Conclusion

- Acknowledgement

- Conflicts of Interest

- References