Research Article

Research Article

Prediction of Self-Healing Efficiency of Cementitious Composites Using Artificial Neural Network

Vesna Grujoska1*, Todorka Samardzioska2 and Silvana Petrusheva2*

1PhD student, Faculty of Civil Engineering, Ss. Cyril and Methodius University in Skopje, Macedonia

2Full Professor, Faculty of Civil Engineering, Ss. Cyril and Methodius University in Skopje, Macedonia

Vesna Grujoska, PhD Student, Ss. Cyril and Methodius University in Skopje, Faculty of Civil Engineering, 24 Partizanski odredi blvd, 1000 Skopje, Macedonia

Received Date:August 26, 2024; Published Date:September 09, 2024

Abstract

Concrete structures are subjected to appearance of micro-sized cracks, which can provide route to penetration of harmful substances in the concrete structure, although they do not cause significant structural damage. As a result, concrete structure degradation and corrosion of the reinforcement can occur. Self- healing concrete is a material created in response to the high requirements for maintenance and repair of structures. Although there are several mechanisms used for self-healing, autonomous self-healing is attracting special attention due to the efficiency that has been demonstrated in laboratory tests over the years. However, self-healing concrete brings a certain complication to the process of obtaining the material and, of course, a higher cost. With software modeling application in the area of self-healing concrete, time and money will be saved, but also standardization procedure will be accelerated and the concrete will start with mass production as soon as possible.Data collection of previously published papers in the area of bacteria-based self-healing concrete is conducted for the purpose of this paper. Data modeling with DTREG software using GRNN (General regression neural network) model is a pivot of the current work. The most influential factors for self-healing cementitious composites through 24 variables are entered to evaluate self-healing. Mean absolute percentage error MAPE=7.29 and coefficient of determination R2=92.62% were taken as estimators for the accuracy of the model.

Keywords:Self-healing; cementitious composite; software modeling; neural network

Abbreviations:GRNN: General Regression Neural Network; MAPE: Mean Absolute Percentage Error, RWT: Regained Water Tightness; GM: Growth Media; ANN: Artificial Neural Networks; RBF: Radial Basis Function

Introduction

Concrete is the most used building material worldwide, which implies production of huge quantities. In the last decade, the number of concrete structures is rapidly growing, but the concept of urban planning is collapsing. According to Justo - Reinoso et al. [1], this period may be remembered as the “concrete era” for future generations. The superiority of concrete over other materials is due to its properties and the low cost of the components that are part of its composition. Concrete is susceptible of cracking due to its low tensile strength and thereby appearance of cracks is reason for creating paths in the concrete structure for dangerous substances, as chlorides and sulfates, and eventually appearance of reinforcement corrosion. In addition, the low degree of sustainability places this material in the environmentally “non-friendly” category. For example, according to the research of Bagga et al. [2], around 8% of the main anthropogenic CO2 emission is due to the production of cement (Portland cement clinker).

Small cracks that are in the order of size of 0.2-0.3 mm are the reason for the penetration of harmful substances into the concrete structure, Jonkers [3]. Maintenance and rehabilitation are necessary to prolong the life span of the concrete structures. Construction and maintenance costs are serious financial moment. In developed countries such as Great Britain, in the last decade the costs of maintenance and rehabilitation reached almost half (46.4%) of the total budget allocated to infrastructure, Tan et al. [4]. Self-healing concrete is a material that has been proposed as a technology that can response to the challenging maintains and repairing costs by automatically repairing cracks. Self-healing process can happen autogenously or autonomously, depending on the used mechanism. Autogenous healing is more natural process that cannot be fully controlled and the crack width that can be healed is limited to 0.2-0.3mm compared to the autonomous healing. A crack width up to 0.97 mm can heal with use of appropriate chemical and biological healing agent added to the cement composite, Wang et al. [5]. Bacteria based self-healing concrete it’s a promising and effective way of achieving self-healing according to the conducted experiments so far. Experimental work can be really expensive and time-consuming process. On the other hand, implementation of selfhealing cementitious composite materials in massive production is becoming a huge necessity so the compromise in between is of urgent meter.

Artificial intelligence (predictive modeling) is a promising method for getting fast and accurate results of self-healing cementitious composites that cost significantly less in comparison to the laboratory work. Creating a database for a specific segment of self-healing cementitious composites is a need for future research as well as for standardizing the process itself. Software modeling would speed up the research process for the material, especially when it comes to the specific bacterial concrete, and direct it more quickly to everyday use. By including a sufficient number of parameters, self-healing concrete modeling with the addition of bacteria would be a reliable way of obtaining results and a major step in this field. In this paper, the main attention is focused on autonomous selfhealing, by adding bacteria to the cement composite mixture, as one of the most current self-healing approaches. For the purposes of this research a database of published papers from 2011 to 2023 has been created. Selecting contemporary literature is considered advantageous regarding the amplification of amount of work lately. Systematization of data is a key factor in creating a model that will be consistent and model that include the most influential factors of self-healing. The software modeling of the data was done using the DTREG software package, with the GRNN (General regression neural network) model. 24 variables are used as input data which are crucial in the process. Evaluation of the accuracy of the model was done using MAPE and R2 parameters.

State-of-the-art

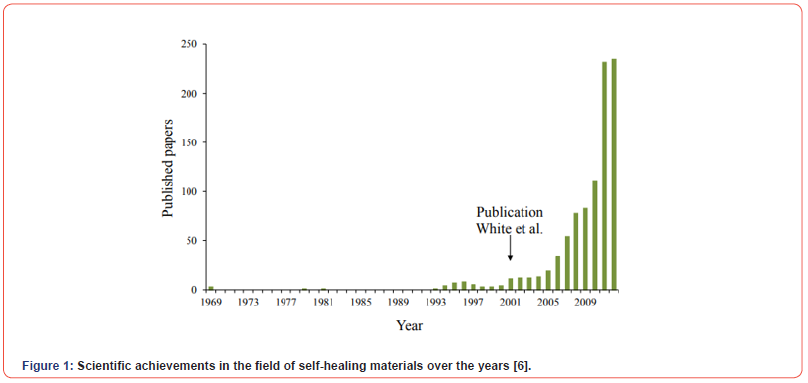

The evolution of “smart” materials over the last decade is truly remarkable. Even though the concept of self- healing cementitious composites is known for a longer period, the last two decades mark the era of self- healing concrete. A large number of experimental studies have contributed to the development of a material that mimic the healing nature of human body. Van Tittelboom, De Belie [6] reviewed the development of research on self-healing materials, diagrammatically showing the increase in the publication of scientific papers on this type of materials, Figure 1. According to them, research by White et al. in 2001 on self-healing in polymerbased materials is considered an impulse that intensified research in the field of self-healing materials. There are several teams across Europe and the world working seriously on self-healing cementitious composites.

Initial research that is more intensive begins with the research of Jonkers, Thijssen et al. [7] on bacterial concrete, who investigated self-healing concrete with metabolic mineral production by directly adding the bacteria Bacillus cohnii and calcium lactate to the concrete mix. Results showed that on the control samples at the age of 7 and 28 days, particles with a size of 1-5 μm appeared on the surface of the crack. In contrast to the control samples, in the samples that contained bacteria and calcium lactate, the size of the mineral particles that appeared were 20-80 μm, but only in the 7 days old samples. While in the samples at the age of 28 days, this influence was unnoticeable. This is a consequence of the fact that survival rate of the bacteria when added unprotected in the concrete mixture is poor.

As a solution to the short lifespan of the bacteria, protection is required by encapsulating the self-healing agent in protective material. Different types of protection have been used: microcapsules [5,8], light aggregate [9-11], silica gel [12] (Table 1). Wiktor et al. [9] performed a self-healing test on concrete with a two-component self-healing agent. In order to prolong the bacteria life, bacteria spores and calcium lactate were encapsulated in lightweight aggregate - particles of expanded clay. Bacteria viability is a crucial factor so self-healing can be achieved for extended period during serviceability of the concrete structure. The results of this research showed that indeed encapsulating the two-component biochemical self-healing agent in expanded clay significantly extended the time for successful survival of the bacteria. Over a period of 100 days, the O2 oxygen consumption test as well as microscopic observation showed that the bacteria was still viable, thus demonstrating the effectiveness of the encapsulation. Tziviloglou et al. [13] added water permeability test as another indication to evaluate self-healing. Expanded clay as an encapsulation material was used to protect the bacteria. Two different healing regimes, wet-dry cycles and water submersion, were used that turns out to be an important parameter in the final result. Microscopic analysis and water permeability test results followed the same trend. When fully immersed in water, tested after 28 and 56 days, the reference, control and bacteria-containing samples showed visible crack closure, partial or full, as well as increase of the recovery of water tightness. Referent (REF) samples showed regained water tightness (RWT) 71% and 80% and Control (CTRL) samples showed RWT of 31% and 82% for 28 and 56 days, respectively, in underwater healing regime. For bacteria samples in same regime RWT was 69% and 91% for 28 and 56 days respectively. While, on the other hand, for the samples that were exposed to wet-dry cycles, the reference and control samples showed a very low value of RWT. In contrast to this, bacterial samples that were cured in the same regime showed 98% recovery of properties in terms of water permeability after 56 days of curing.

Table:Different type of encapsulation material, bacteria and growth media.

Replacing a percentage of the aggregate with expanded perlite in which the bacteria and nutrients were encapsulated was investigated by Alazharie et al. [10]. For the first time in this research, the optimal number of bacteria, needed for the selfhealing process to take place, was analyzed. It has been shown that a certain minimum number of spores of the bacteria is required for the self-healing process itself to occur. In their work, when replacing 20% of the stone aggregate with expanded clay, the optimal most effective ratio of spores to calcium precursor (calcium acetate) is 8x109 spores/g. Microencapsulation as a way to protect bacteria was considered by Wang et al. [5], and Paine et al. [8]. Maximum width of the healed crack in the bacterial samples was 970 μm, which is 4 times larger than the non-bacterial samples, [5]. Five incubation regimes were investigated for selfhealing evaluation: 20°, RH>95%, complete immersion in water, immersion in deposition medium, wet-dry cycles in water, and wetdry cycles in deposition medium. This paper also confirms results of Tziviloglou et al. [13] that bacterial samples are stimulated to fill cracks when exposed to wet-dry cycles healing regime. The microcapsules they used were resistant to high pH and sensitive to moisture. In addition to the bacteria that were incorporated into the microcapsules, yeast extract, calcium nitrate and urea were also added, which were incorporated together with the microcapsules during the mixing process. The added microcapsules significantly affected the compressive and flexural strength. Compressive strength decreased significantly around 33% to 47% in samples containing 5% replacement of microcapsules impregnated with bacteria and nutrients. Since it is a question of unacceptable values of compressive strength, the tests led to the conclusion that it is necessary to reduce and limit the number of microcapsules to a maximum of 3%.

Paine, Alazhari et al. [14] separately encapsulated the nutrients (calcium acetate and yeast extract) in perlite to minimize the potential for bacterial activation and growth prior to crack formation. To prevent leakage of the encapsulated substances in the perlite, the perlite was protected with a double layer of protection: a layer of sodium silicate and a layer of Portland cement with the addition of fly ash. In many structures under exploitation, the carbonation process can occur before crack formation occurs, Tan et al. [11]. In such conditions, the only source of calcium ions Ca2+ that are needed for the formation of the final product, calcium carbonate, is only available by the added calcium directly or by encapsulation in the concrete mix. Light concrete granules (aerated concrete granules) were used to encapsulate the spores and growth medium (GM) and were protected by a layer of polyvinyl acetate. 85% curing in the case of non-carbonized concrete and 1g of yeast extract (when bacteria and GM are encapsulated) versus 53% curing of carbonized concrete. 100% curing versus 94% curing under the same conditions only by increasing the amount of yeast extract per 4 g.

Ceramsite as a carrier of bacteria was investigated by Chen et al. [17]. Nutrients (yeast extract and sucrose) and calcium nitrate were also separately encapsulated in ceramsite, and in a certain mixture only glucose was added to produce CO₂. The samples that contained nutrients and bacteria protected in expanded clay showed the best results in terms of water permeability, but also in terms of strength, specifically flexural strength, the results showed that the degree of surface healing was 87.5%.

Rauf et al. [19] investigated using different types of natural fibers as bacterial carriers with different type of bacteria. The selfhealing evaluation method was done, as in the above-mentioned example, by evaluating the difference in crack width before and after healing. The mechanical properties were also examined. Three different types of bacteria Bacillus subtilis, Bacillus cohnii and Bacillus sphaericus were tested along with calcium lactate and urea. Three types of fibers (flax, jute and coir) were used to protect the bacteria. Flax fibers provided better protection of the bacteria, resulting in better self-healing and regain of compressive strength. Greatest precipitation of calcium carbonate was obtained by the use of Bacillus sphearicus, evenly distributed along the entire length of the crack. 75-85% and 60-65% surface healing was obtained using fiber-reinforced concrete at 7 and 28 days pre-cracked specimens, respectively.

Wang, Tittellboom et al., [15] conducted tests on bacteria immobilized in silica gel and polyurethane. Due to the higher activity, immobilized bacteria in silica gel allows the creation of a larger amount of CaCO3 (25% by mass) compared to immobilized bacteria in polyurethane (11% by mass). On the other hand, mortar samples with bacteria immobilized in polyurethane showed a higher regained strength (60%) and a lower coefficient of water permeability (10-10-10-11 m/s) compared to the samples cured with bacteria immobilized in silica gel in which the recovered strength was only 5%, and the coefficient of water permeability (10-7-10-9 m/s).

Addition of fly ash in concrete in three different amounts (10, 20 and 30% of cement weight) was investigated in combination with three different concentrations of the bacterium Sporoscarcina pasteurii 10^3, 10^5 and 10^7) cells/ml), Chahal et al. [20]. The water absorption test showed four times reduced water absorption at a bacterial concentration of 10^5 cells/ml. Experimental testing of self-healing materials is time consuming and expensive process. As a response to this, software modeling (machine learning) is a rational solution to provide faster and economically more convenient way of achieving big scale implementation of self-healing concrete. Number of publications in the field of using machine learning for data modeling of self-healing concrete is not remarkably high due to the complexity and inconsistency of the data. Also, a lot of factors affecting self-healing process so the systematization of data is slow.

Suleiman and Nehdi, 2017 [21] are among the first to investigate modeling the self-healing process with neural networks. In their papers only autogenous self-healing was observed, which is said to be more compatible for modeling than autonomous self-healing due to the simpler mixture composition. The database included 1462 datasets with 11 input parameters for training the network, and the self-healing response was evaluated as one output parameter. With a similar amount of database was the examination of 1417 data by Huang et al. [22], which predicted autogenous self-healing, but with a comparison of six different algorithms. Zhuang and Zhou [23], made a prediction of self-healing concrete with addition of bacteria with 1223 data, but they only considered a few basic parameters, amount of bacteria, initial crack and healing time.

Methodology

Model preparation

For the purpose of this research, autonomous self-healing with bacteria was considered, as a challenging matter due to many factors affecting the process. Data are extracted from recently published papers (selected literature from 2011-2023). Process of selection of compatible and comparable data is long and not very simple due to the variation that self-healing cementitious composites undergo in the testing process and components included in the mixture. Bacterial cementitious composites are undergoing chemical and physical reactions; therefore, variety of factors are involved. As a drawback in data collection from published papers is the frequent incomplete report of the laboratory work and the incompatible units that are very difficult to convert.

In order to get as close as possible to an “ideal model”, a larger number of parameters that affect self-healing have been taken into account in this modeling (Table 2). The amount of the basic components included in the composition of a traditional concrete mixture (cement, water, fine and coarse aggregate and additives to improve the properties of the mortar/concrete mixture) as well as additives to the concrete to help the self- healing process (bacteria, calcium precursor, etc.) were included as input data. Storage conditions of the samples and the duration of the process are also taken in consideration. An output parameter (target value) is the percentage of healing, which is evaluated by visual measurement of the crack closure. In order to avoid large oscillations in the values, the data were normalized with the function y=ln (x+1).

Table:Variables included in the data modeling.

DTREG (model GRNN)

Technology development is bringing novelties and opportunities to make our lives easier. Data modeling is becoming popular in many scientific areas considered for very challenging. Predictive modeling (part of the field of artificial intelligence) works on the principle of recognizing pattern based on the gained “experience”.

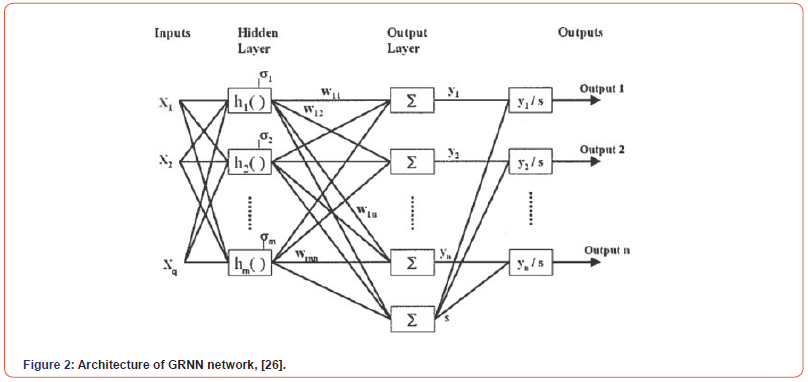

Artificial neural networks (ANN) are computational models with wide range of application in many scientific areas. They consist of numerous interconnected processing elements (neurons) that are inspired by the functionality of the human brain. The neurons receive the input data from outside or from the neighboring neuron and pass it on to another connected neuron. The data is entered into the network through the so-called input layer and is gradually processed until it reaches the output layer. Input data are variables chosen to be the most significant factors affecting the target variable, in order to more accurately predict the target variable. In this paper, the model of GRNN (General regression neural network) is considered. GRNN was proposed by Specht, [24]. This model processes data quickly, does not use backpropagation, and is highly accurate because it uses a Gaussian function as a kernel function. Radial basis function (also called a kernel function) is applied to the distance to compute the influence of each point. Sigma (σ) values of the function define the spread of the radial basis function, [25], and defines the region of influence of the neighborhood around each center in the RBF layer. The architecture of GRNN network is presented in Figure 2.

Results and Discussion

The amount of data that will guide the calculation is certainly important for improvement of the model results. In addition, the compatibility and similarity of data is another key factor in order to get more real scenario. By simply adding variables that do not affect the entire data set, the balance of the created model is sure to be disturbed. DTREG software, model GRNN (General Regression Neural Network) was implemented for the purpose of this study. This model was selected as the most favorable for this amount of data. Nine papers were carefully selected to be the most compatible and mutually similar. 24 predictor variables (categorical and continuous) and one target variable (continuous) were used for the network training. The type of analysis was regression and leaveone- out validation was used, and N models were tested. (N-1) rows are used for creation of every model and the N-th row is used for testing of the model.

Sigma values control the radius of influence of each point in the model, [25]. In this data, modeling sigma values is chosen for each variable individually. Sigma values are optimized to establish good generalization performance during the training. Standard parameters were used to evaluate the accuracy of the model: MAPE (mean absolute percentage error) and R2 (coefficient of determination). The MAPE parameter shows the percentage of error that occurs between the data used for training and the test data. A lower value of this coefficient indicates a higher accuracy of the model. The R2 parameter shows how well the data fit into the approximation function obtained from the model and it is a measure of the global fit of the model. A higher value of this coefficient gives a higher accuracy of the model. The value for MAPE = 7.29, and the coefficient R2= 92.62% were obtained in the conducted analysis, which confirms that the model is favorable in terms of selected data. The coefficient of correlation between actual and predicted values is Q=0.963. Results obtained from the software analysis are given in Table 3.

Table:Analysis of variance.

The percent of importance can be calculated for each of the input variables, based on the influence of every variable on the model. This tool helps the model improvement by eliminating the less significant variables. Initial crack size stands out from all other input parameters with 100% importance, indicating model reliability knowing that the width of crack is certainly prominent factor for the process of self- healing. Curing time as well as incubation conditions were also contributing with significant percent in the overall importance of variables [26].

Conclusion

Self-healing cementitious composites show potential for future widespread use when it comes to improving material durability. The results of numerous tests show that micro-cracks, which are the main source of harmful substances in the concrete structure, can be prevented in a timely manner, which will prevent corrosion of the reinforcement and damage to the concrete structure, which can cause fatal consequences. Since we are talking about a material that is still in laboratory conditions (although there are several practical applications in constructions around the world), applying this material in practice as soon as possible would mean saving and reducing the maintenance and repair budget. The prominent factor, per se, is the amount of data to get a more accurate model. In the area of self-healing cementitious composites, the urge is even higher to get as much as possible data, because many components are included/excluded in order to get the standardized material and to gain maximum efficiency. Variety of factors dominate and create scattered data base which is very difficult to control.

Artificial intelligence methods are popular in many areas, including civil engineering. Application of software modeling that simulates the human way of functioning of the brain is made possible using neural networks. It is very important to create a database with selected important parameters and systematize the data in order to obtain accurate model. The DTREG software, GRNN model for predicting self-healing was used for this research. The input parameters are chosen to include as many variables as possible and thus to describe the process in detail to obtain maximum accuracy. The percentage of self-healing is the output parameter used in this software. Generated parameters that determine the accuracy of the model are MAPE=7.29 and R2= 92.62%. This means that the percentage error is 7.29, which is reasonable level regarding the fact that the used data values are from laboratory experiments. According to the obtained values, the model shows good matching of validation data.

References

- Justo Reonoso I, Heath A, Gebhard S, Paine K (2021) Aerobic non-ureolytic bacteria-based self-healing cementitious composites: A comprehensive review. Journal of Building Engineering 42(7): 102834.

- Bagga M, Hamley-Bennett C, Alex A, Freeman B L, Justo Reinos I, et al. (2022). Advancements in bacteria based self-healing concrete and the promise of modelling. Construction and Building Materials 358(3): 129412.

- Jonkers HM (2011) Bacteria-based self-healing concrete. Heron 56: 5–16.

- Tan L, Reeksting B, Justo-Reinoso I, Ferrandiz-Mas V, Heath A, et al. (2023) The effect of oxygen and water on the provision of crack closure in bacteria-based self-healing cementitious composites. Cement and Concrete Composites 142: 105201.

- Wang J Y, Soens H, Verstraete W, De Belie N (2014) Self-healing concrete by use of microencapsulated bacterial spores. Cem Concr Res 56: 139–152.

- Van Tittelboom K, De Belie N, (2013) Self-healing in cementitious materials-A review. Materials 6: 2182–2217.

- Jonkers H M, Thijssen A, Muyzer G, Copuroglu O, Schlangen E (2010) Application of bacteria as self- healing agent for the development of sustainable concrete. Ecol Eng 36: 230–235.

- Paine K, Horne I, Tan L, Sharma T, Heath A, et al. (2018) Microencapsulated spores and growth media for self-healing mortars. Life-Cycle Anal Assess Civ Eng Towar an Integr Vis - Proc 6th Int Symp Life-Cycle Civ Eng IALCCE 2019: 2247–2253.

- Wiktor V, Jonkers HM (2011) Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem Concr Compos 33: 763–770.

- Alazhari M, Sharma T, Heath A, Cooper R, Paine K, (2018) Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr Build Mater 160: 610–619.

- Tan L, Reeksting B, Ferrandiz-Mas V, Heath A, Gebhard S, et al. (2020) Effect of carbonation on bacteria- based self-healing of cementitious composites. Constr Build Mater 257: 119501.

- Van Tittelboom K, De Belie N, De Muynck W, Verstraete W (2010) Use of bacteria to repair cracks in concrete. Cem Concr Res 40: 157–166.

- Tziviloglou E, Wiktor V, Jonkers H M, Schlangen E (2016) Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr Build Mater 122: 118–125.

- Paine K, Alazhari M, Sharma T, Cooper R Heath (2016) Design and performance of bacteria-based self- healing concrete. 9th International Concrete Conference, Environment, Efficiency and Economic Challenges for, Concrete (2016): 545–554.

- Wang J, Van Tittelboom K, De Belie N, Verstraete W (2012) Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. January 2012, Construction and Building Materials 26(1): 532–540.

- Wang JY, De Belie N, Verstraete W (2012) Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J Ind Microbiol Biotechnol 39: 567–577.

- Chen H, Qian C, Huang H (2016) Self-healing cementitious materials based on bacteria and nutrients immobilized respectively. Constr Build Mater 126: 297–303.

- Khaliq W, Ehsan MB (2016) Crack healing in concrete using various bio influenced self-healing techniques. Constr Build Mater 102: 349–357.

- Rauf M, Khaliq W, Khushnood R A, Ahmed I (2020) Comparative performance of different bacteria immobilized in natural fibers for self-healing in concrete. Construction and Building Materials 258: 119578.

- Chahal N, Siddique R, Rajor A (2012) Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr Build Mater 28: 351–356.

- Suleiman RA, Nehdi ML (2017) Modeling Self-Healing of Concrete Using Hybrid Genetic Algorithm– Artificial Neural Network. Materials (Basel) 10: 135.

- Huang X, Wasouf M, Sresakoolchai J, Kaewunruen S (2021) Prediction of healing performance of autogenous healing concrete using machine learning. Materials (Basel) 14: 1–16.

- Zhuang X, Zhou S, (2019) The prediction of self-healing capacity of bacteria-based concrete using machine learning approaches. Comput Mater Contin 59: 57–77.

- Specht DF (1991) A General Regression Neural Network. IEEE Transactions on neural networks 2(6): 568-576.

- Sherrod P (2013) Predictive modelig software DTREG.

- Samardzioska T, Pancovska ZV, Petruseva S, (2021) Predicting energy consumption of buildings based on their geometrical properties using artifical neural network. South Florida Journal of Development, Miami 2(1).

-

Vesna Grujoska*, Todorka Samardzioska and Silvana Petrusheva. Prediction of Self-Healing Efficiency of Cementitious Composites Using Artificial Neural Network. Cur Trends Civil & Struct Eng. 11(3): 2024. CTCSE.MS.ID.000762.

-

Self-healing; cementitious composite; software modeling; neural network; Iris Publishers; Iris Publishers Group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.