Mini Review

Mini Review

Mechanical Properties and Fatigue Behaviour of Corroded High Strength Steel Strand

Ka Fai Yuen*

Department of Civil and Environmental Engineering, The Hong Kong Polytechnic University, Kowloon, Hong Kong

Ka Fai Yuen, Department of Civil and Environmental Engineering, The Hong Kong Polytechnic University, Kowloon, Hong Kong

Received Date:February 02, 2024; Published Date:February 21, 2024

Introduction

High strength steel strands are widely employed in posttensioning bridges due to their exceptional mechanical properties, particularly their ultra-high tensile strength of approximately 1860 MPa. This characteristic enables them to effectively bear the load of the bridge and ensures the overall structural integrity. However, the occurrence of corrosion fatigue poses a significant challenge in the utilization of steel strands in bridges.

Corrosion fatigue is a complex phenomenon resulting from the combined effects of cyclic loading and corrosion. During the operational lifespan of bridges, steel strands are subjected to repeated cyclic loads due to temperature variations and wind effects. Each cycle of loading and unloading can initiate and propagate microscopic cracks within the material. These cracks progressively grow with each loading cycle, and cause material failure. In the presence of incomplete grouting and chloride deposition, pit may form on the surface of the strands, and act as stress concentration point which amplifies local stress [1,2]. Under cyclic loading, the stresses around these pits become more significant. Consequently, these pits significantly influence the fatigue life of steel strands, leading to the phenomenon of corrosion fatigue. Since corrosion fatigue poses a substantial risk to the performance and service life of high strength steel strands used in bridge applications, it is crucial to comprehensively understand the effects of corrosion fatigue on the service life of these strands to ensure the safety of bridges and develop appropriate maintenance strategies. The aim of this article is to review experimental studies on the effects of corrosion on both mechanical properties and fatigue life of steel strands. By critically examining existing research studies and experimental investigations, the article explores and discusses the effects of various testing parameters on fatigue life.

Mechanical Properties of Corroded Strand

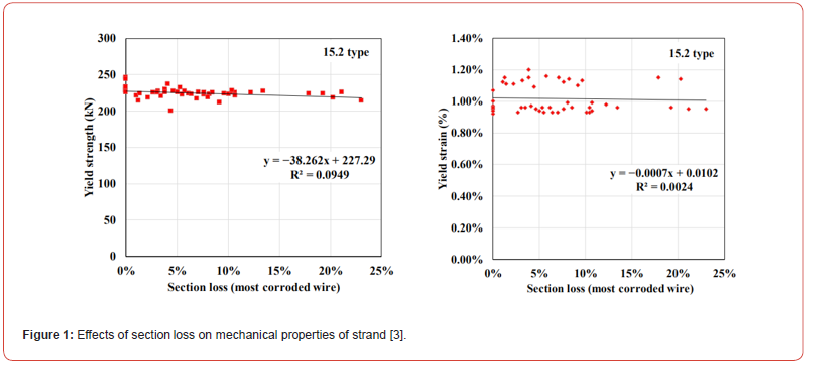

Experimental studies have been extensively conducted to investigate the effects of corrosion on the mechanical properties of steel strand. One effective way is to measure the section loss of the strand before and after corrosion, and correlate with their mechanical properties. In research conducted by Jeon et al. [3], 19 seven-wired strands with a nominal diameter of 15.2mm was collected from a post-tensioned bridge. Figure 1a & 1b shows the reduction of both yield strength and yield strain at different level of section loss. It was found that the section loss did not have a significant impact on both yield strength and yield strain. The correlation coefficient for section loss and yield strength was only 0.0949, and 0.0024 for section loss and yield strain.

Residual Fatigue Life of Corroded Strand

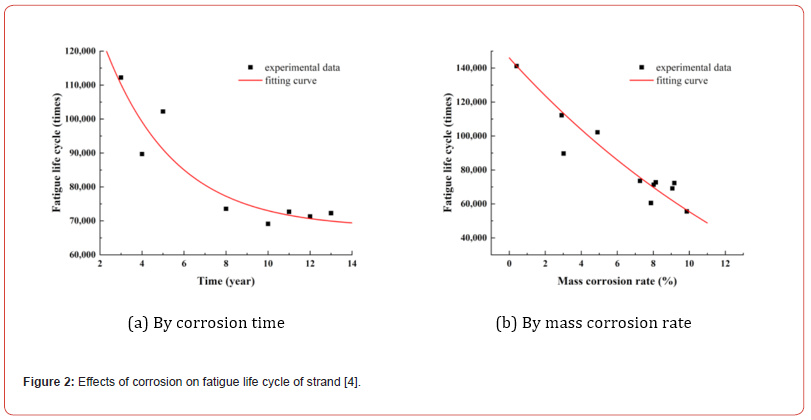

Although the effects of corrosion on yield strength of strand is insignificant, Fan et al. showed that both exposure time and mass corrosion rate have significant influence on its fatigue life cycle [4]. Figure 2a & 2b shows relationship between exposure time and fatigue life where an exponential decay of fatigue life along with exposure time was observed. As exposure period extends from 2 years to 13 years, fatigue life may drop by 36%. Similar to mass corrosion rate, while the strand may withstand 140,000 cycles at 0% corrosion rate, it dropped by 50% as corrosion rate increased to 8 %.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Carsana M, L Bertolini (2015) Corrosion failure of post-tensioning tendons in alkaline and chloride-free segregated grout: a case study. Structure and Infrastructure Engineering 11(3): 402-411.

- Lau K, I Lasa, M Paredes (2013) Corrosion failure of post-Tensioned tendons in presence of deficient grout. NACE - International Corrosion Conference Series.

- Jeon CN Cuong, C Shim (2020) Assessment of Mechanical Properties of Corroded Prestressing Strands. Applied Sciences 10: 4055.

- Hartt WH, SK Lee (2018) Corrosion Forecasting and Failure Projection of Post-Tensioned Tendons in Deficient Cementitious Grout.

-

Ka Fai Yuen*. Mechanical Properties and Fatigue Behaviour of Corroded High Strength Steel Strand. Cur Trends Civil & Struct Eng. 10(3): 2024. CTCSE.MS.ID.000740.

-

High Strength Steel Strand; Fatigue Behaviour; bridges; Corroded Strand; Iris Publishers, Iris Indexing Sites

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.