Short Communication

Short Communication

Guidelines for Structural Health Monitoring

Suresh Bhalla1, Naveet Kaur2* and Rohit Gogna3

1Professor, Department of Civil Engineering, Indian Institute of Technology (IIT), President of ISHMS, Delhi, India

2Vice President ISHMS, New Delhi, India

3Founder and Chairman, Sanrachna Prahri Private Limited, General Secretary of ISHMS, India

Naveet Kaur, Vice President ISHMS, New Delhi, India

Received Date:January 20, 2025; Published Date:February 07, 2025

Abstract

The Indian Structural Health Monitoring Society (ISHMS) has introduced the Guidelines for Structural Health Monitoring (SHM) to address the urgent need for systematic monitoring and maintenance of India’s rapidly growing infrastructure. Approved in the 4th General Body Meeting on 10 June 2024, this document provides a foundational framework for implementing SHM across critical structures, ensuring informed decisionmaking through data-driven approaches. The guidelines recommend SHM implementation from the construction phase or at the earliest for existing structures, targeting high-rise buildings, specific types of bridges, nuclear power plants, vibration-sensitive structures, and large-span domes or spaces. Key parameters to be monitored include static and dynamic metrics such as deflection, strain, temperature, and natural frequencies, with a focus on deploying advanced sensor technologies like vibrating wire strain gauges, fiber-optic sensors, and piezoelectric sensors. Instrumentation modes range from manual to IoT-enabled systems, with a preference for automated, real-time data acquisition and analysis. The guidelines emphasize regular reporting, threshold-based alert generation, and feature extraction to assess structural conditions effectively. Specific structural components such as foundations, bridge decks, and building joints are prioritized for instrumentation to ensure compliance with national codes like IRC 112 and IS 1893. This document serves as a comprehensive guide for stakeholders to adopt modern SHM practices, reducing downtime, optimizing maintenance, and enhancing the longevity and safety of infrastructure.

Keywords: SHM; Guidelines; bridges; Concrete structures

Abbreviations:SHM: Structural Health Monitoring; RTF: Run to Failure; GC: Governing Council; GCM: Governing Council Meeting; ISHMS: Indian Structural Health Monitoring Society; PZT: Lead zirconate titanate; CVS: Concrete vibration sensors; MFC: Macro-Fiber composite; IoT: internet of things

Introduction

India is witnessing a high surge in construction activities as part of the infrastructure boost accompanying its strong economic growth. Numerous bridges, tall buildings, airports, railway stations and similar structures are currently under various stages of construction all over the country. Unfortunately, not enough seems to be done with regard to the monitoring and maintenance of the ever-growing infrastructure repository. There is no code of practice at the present related to structural health monitoring (SHM) in India. The Indian infrastructure industry typically follows the “run to failure (RTF)” model as far maintenance in concerned. This means ignoring any monitoring or maintenance needs till some problem creeps in. No sensor-based data driven scientific approach is often followed. SHM is defined as a continuous sensor-based data driven approach aimed to facilitate informed decision about current health condition of the structure. This is the right time Indian infrastructure industry adopts modern SHM sensors and related technologies so that decisions backed by scientific data are arrived at any future instant of time rather than relying on the RTF approach leading to greater downtime as well as higher recovery cost for infrastructure. This document is prepared by the Governing Council (GC) of the Indian Structural Health Monitoring Society (ISHMS) based on its body of expert members and also after receiving feedback from industry experts as well as relevant government agencies. The second General Body Meeting (GBM) held on 11 Dec 2023 decided to prepare a document serving as basic guideline to various stakeholders. The Governing Council Meeting (GCM) held on 12 January 2024 decided to receive suggestions from industry also. Accordingly, online surveys were conducted from 06 March 2024 to receive inputs from industry and other stakeholders. The document was approved in the Fourth GBM held on 10 June 2024. The document attempts to provide basic guidelines to stakeholders to implement SHM in their structures.

Structures on which should SHM be implemented?

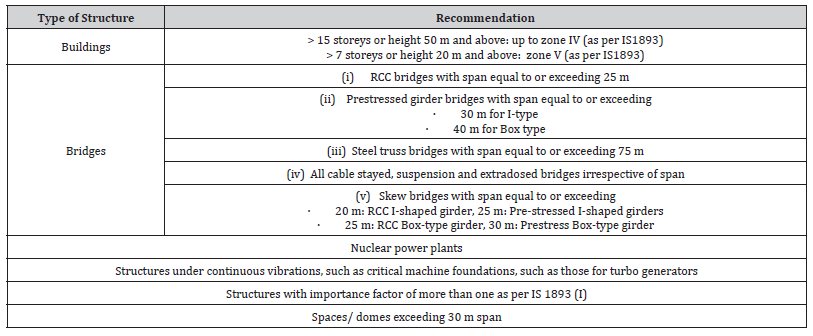

It is recommended that SHM be implemented on category of structures mentioned in Table 1 right from the construction stage. In case of existing structures, it is recommended to implement SHM at the earliest possible:

Table 1:Structures where it is recommended to implement SHM.

Parameters To Be Monitored as Part of SHM

Generally, SHM involves monitoring static and dynamic

parameters. Concerned agencies may decide to instrument sensors

for measuring following parameters:

a. Static: Deflection, strain, temperature

b. Dynamic: Deflection, strain, at least first natural frequency

and mode shape

Sensors

Sensors play crucial role in the process of SHM. Table 2 provides the list of commercially available sensors, which the concerned agencies might consider while instrumenting a structure

Table 2:List of commercially available sensors for SHM.

Instrumentation Cum Measurement Mode

Depending upon the expertise and budget available, concerned agencies may decide to adopt either manual or internet of things (IoT) based automatic mode (preferred) for data acquisition from the instrumented sensors. If IoT based instrumentation is adopted, the data should preferably be available to users in online real-time graphical user interface. Suitable sampling interval be adopted for static and dynamic measurement such that it is able to enable appropriate feature extraction, whether static strain/ deflection or dynamic parameters such as natural frequencies, mode shapes or any structural signature representative of the condition of the structure. Sampling should be accompanied by a report generation, which should be at least monthly for IoT based monitoring and at least six monthly for manual SHM. The measured data should be analysed to enable suitable feature extraction based on the particular measurement and utilizing the currently available SHM literature. In case of IoT mode, the system should be capable of generating alert/ warning in case of threshold exceedance.

Structural Components to be Instrumented

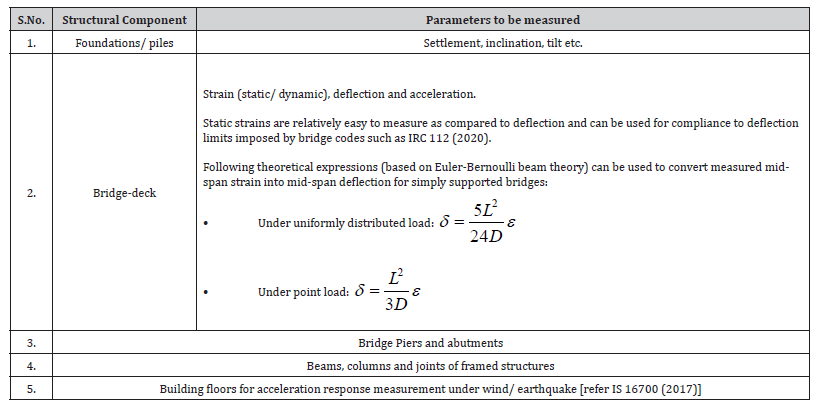

It is recommended to instrument the components of structures mentioned in Table 3 [1-3].

Table 3:List of commercially available sensors for SHM.

Acknowledgements

The authors gratefully acknowledge all the GC members of ISHMS for the year 2024-25 including Mr Sayed Sameer Hasan (Financial Secretary), Shipra Prakash (GC Member), Dattar Singh Aulakh (GC Member), Dr. S K Dhawan (GC Member), Dr. Visalakshi Talakokula (GC Member) and Dr. Sumedha Moharana for their support in bringing out these SHM guidelines.

-

Suresh Bhalla, Naveet Kaur* and Rohit Gogna. Guidelines for Structural Health Monitoring. Cur Trends Civil & Struct Eng. 11(4): 2025. CTCSE.MS.ID.000767.

-

: SHM; Guidelines; bridges; Concrete structures; Iris Publishers; Iris Publishers Group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.