Review Article

Review Article

Geotechnical Practice of Strengthening the Foundation Base of a Three-Storey Administrative Building

Sokolov Sergey Nikolaevich*

Head of the Department of Construction Technologies, Geotechnics and Economics of Construction, I.N. Ulyanov Chuv SU, Director of LLC NPF FORST, Ph.D.,Associate Professor, Member of ROMMGiF and ISSMGE, Cheboksary, Russia

Sokolov Sergey Nikolaevich, Head of the Department of Construction Technologies, Geotechnics and Economics of Construction, I.N. Ulyanov Chuv SU, Director of LLC NPF FORST, Ph.D., Associate Professor, Member of ROMMGiF and ISSMGE, Cheboksary, Russia

Received Date:May 01, 2024; Published Date:May 21, 2024

Abstract

Reconstruction of facilities often involves a change in the structural scheme of the building, in connection with which a significant increase in external loads under the existing load-bearing elements is possible. In addition, it is possible to create additional load-bearing structures with correspondingly new foundations. There is an urgent need to increase the load-bearing capacity of the foundation foundations. The arrangement of bored injection piles of reinforcement, arranged according to geotechnical electric discharge technology (ERT piles), is the most acceptable for conditions of especially cramped conditions.

Keywords:geotechnical construction, electrohydraulics, monolithic reinforced concrete grillage, bored injection piles ERT, especially cramped geotechnical conditions.

Introduction

Reconstruction of facilities always faces technical and

technological problems [1-7] associated with the choice of a

technically expedient and economically effective method of

strengthening building structures. This is of particular relevance

for the purpose of strengthening the foundations [8-18]. The

article under consideration discusses the case of strengthening

the foundation base of a three-storey public building under

reconstruction. As a rule, the initial documents for the development

of project documentation are [1-7, 8-18].

a) Conclusion on the results of the engineering and technical

inspection of the building

b) Technical report on the results of engineering and

geological surveys for the preparation of project documentation.

In the engineering-geological structure of the investigated area, in the process of drilling, experimental and laboratory studies of these surveys up to the explored depth of 15.0 m, the following were identified (from top to bottom): Upper Quaternary formations of problematic genesis (prQIII) and Middle Quaternary eluvialdeluvial formations (edQII), overlain from above by technogenic soils. From the surface to a depth of 3.20 m, man-made deposits were exposed throughout the site, represented by brown loam, with the inclusion of small construction debris and soil with a road structure in the roof. At a depth of 2.0-3.2 m (79.11 – 80.62 m) there are Upper Quaternary formations of problematic genesis (prQIII), represented by loess-like, light-brown, grayish-brown, ferruginous sandy loams, with humus points in the roof, with calcareous ties, with gray inclusions, with a thickness of 8.7 m to 10.6 m. Middle Quaternary eluvial-deluvial formations (edQII) exposed under the Upper Quaternary formations of problematic genesis from a depth of 11.70 – 12.60 m (abs. elevation 68.51 – 71.95 m) are represented by brownish-brown, ferruginous, sandy loams, with the inclusion of bedrock (red clay, marl, sand, limestone, etc.).

Based on the analysis of drilling, pilot and laboratory materials in accordance with the standards of the Russian Federation GOST 25100-2020 and GOST 20522-2012 in the section of the studied area, three engineering and geological elements were identified (see Fig. 1): 1. Light sandy loam, hard-plastic loam (tQIV); 2. Sandy loams are sandy, plastic, non-subsidizing (prQIII); 3. Loams are light, sandy, semi-hard (edQII). For the period of engineering and geological surveys (August, 2023), the hydrogeological conditions of the work site are characterized by the absence of groundwater within the drilling depth of up to 15.0 m. During spring floods, heavy rainfall, as well as in case of accidental leaks from waterbearing utilities and runoff of surface water from asphalt surfaces, it is possible to form a local surface water horizon of the “verkhovodka” type at a depth of water-bearing communications - 2.0 m. In accordance with the requirements of Appendix “E” of the Code of Rules SP 22.13330.2016 Updated Edition of SNiP 2.02.01-83* “Foundations of Buildings and Structures”, the value of the maximum additional deformation of the foundation base for single-storey and multi-storey frameless buildings with walls made of brick or large blocks without reinforcement should not exceed 2 cm in a limited operable technical condition of the structure.

Inclined piles of solid cross-section with a drilling diameter of 150 mm, reinforced to the full height with spatial reinforcement cages; Accepted pile markings: SR-17-15 (length 17 m, drill diameter 150mm), SR-16-15 (length 16 m, drill diameter 150 mm), SR-15-15 (length 15 m, drill diameter 150 mm), SR-14-15 (length 14 m, drill diameter 150 mm); Embedding the pile top into a prefabricated reinforced concrete foundation of at least 1000 mm. In the detailed design, special requirements have been developed and adopted to improve the requirements for the installation of ERT bored injection piles: 1. For ERT bored injection piles, use self-compacting fine-grained concrete mixtures of strength class B25, waterproof grades not lower than W8 in accordance with GOST 26633-91, prepared at the construction site or at specialized concrete plants. 2. The concrete mixture must meet the requirements of GOST 7473- 94; 3. Workability of concrete mixture P4... P5, tested by AZNII cone; 4. Water separation of fine-grained concrete mixture should not exceed 2%; 5. The concrete mixture should not have inclusions of crushed stone and gravel with a size of more than 10 mm; 6. For concrete mixtures, use Portland cement without mineral additives with a strength grade of at least M500; 7. Quartz sand serves as an aggregate for concrete. It is allowed to use clean fine sands with a fineness modulus of at least 1.7; 8. The following additives may be used in the manufacture of piles: superplasticizers, hardening accelerators, setting retardants, corrosion inhibitors and antifreeze additives; 9. Tap and technical water for concrete mix, free of sugars and phenols of more than 10 mg/l, petroleum products and fats. Hydrogen index (pH) from 4 to 12.5; 10. It is forbidden to add water to the fine-grained concrete mixture to increase its mobility; 11. Selection of the composition of the concrete mixture with the determination of the composition and amount of additives is carried out by the construction laboratory; 12. Reinforcement of piles is provided for the entire length and is carried out in separate sections of spatial welded frames. Connect these frames to each other by overlapping with the use of binding wire with a diameter of 1.5-2.0 mm; 13. Reinforcement with a diameter of 12 mm of A500C class was adopted as longitudinal bars of the spatial frame. Transverse reinforcement made of reinforcement with a diameter of 8 mm of A240 class. Protective layer of concrete not less than 30 mm; 14. The rigidity of the spatial frame is provided by steel rings made of pipes with a diameter of 54 mm and a wall thickness of at least 3 mm; 15. To provide a protective layer of concrete, centralizers made of steel strips with a width of 20 mm and a thickness of 4 mm are provided in the amount of at least 5 in one cross-section of the reinforcement cage with a step along the length of the frame of no more than 1.5 m; 16. Manual arc welding of spatial frame elements is carried out with electrodes of E42A, E46A, E50A types; 17. It is forbidden to use reinforcement made of 35GS steel for the manufacture of welded frames.

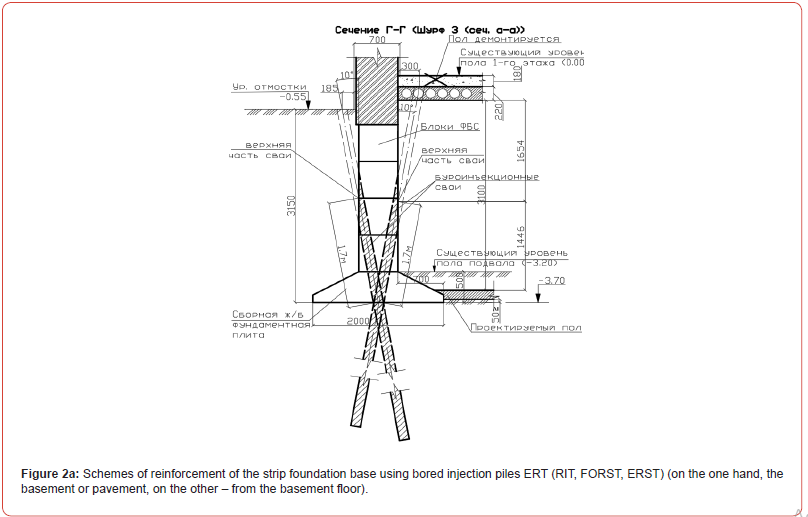

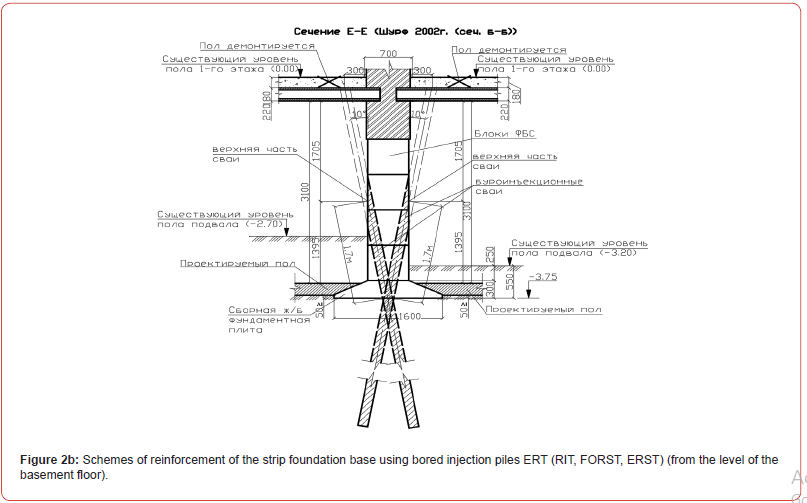

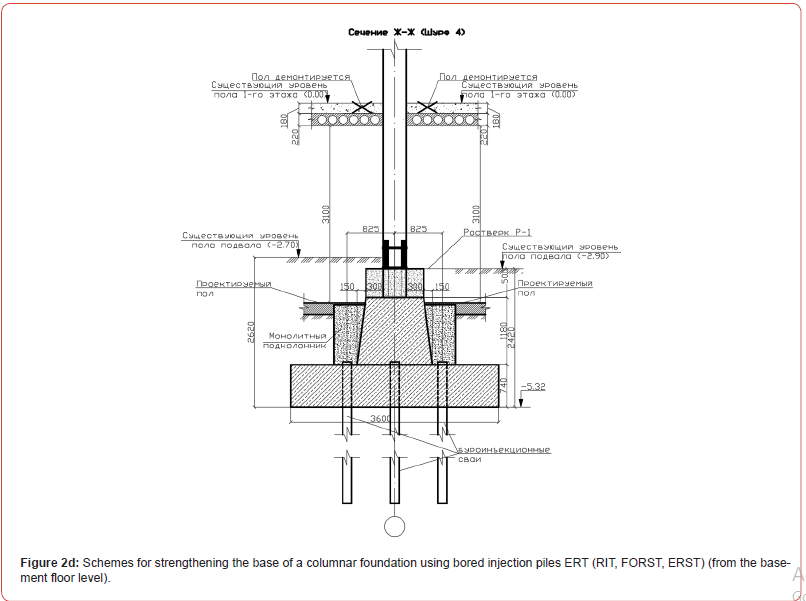

The technological sequence for the manufacture of bored injection piles ERT (RIT, FORST, ERST) includes the following technological operations: 1. Formation of a well of the required depth and diameter by auger drilling; 2. Injection of fine-grained concrete mixture into the borehole; 3. Electric discharge treatment of a well filled with concrete mixture; 4. Installation of spatial frames with their simultaneous docking with each other; 5. Maintenance of the concrete head. In addition, special technical and technological measures have been developed to facilitate the manufacture of bored injection piles ERT: 1. When installing ERT piles, the next well should be arranged at least 2.0 m from the previous one. Drilling of wells next to previously manufactured piles is allowed only after at least 48 hours after the completion of concreting of the latter. 2. Prior to the commencement of work, the protective zones of existing underground and overhead communications, as well as underground structures, shall be indicated with the indication of the protective zone established in accordance with clause 3.22 of SNiP 3.02.01-87 “Earthworks, Bases and Foundations”. 3. In case of detection of underground structures, communications or signs designating them not specified in the working design, the work shall be suspended, representatives of the customer and organizations operating the discovered communications shall be summoned to the place of work, and measures shall be taken to protect the discovered underground devices from damage. It is allowed for the customer to remove existing communications from the work area with the written permission of the operating organizations (Figures 1 & 2).

References

- Ter-Martirosyan AZ, Kivlyuk VP, Isaev IO, Shishkina VV (2022) Analysis of the calculation prerequisites of the geotechnical forecast of new construction for the surrounding development. 9: 57–66.

- Mangushev RA, Nikiforova NS (2017) Technological precipitation of buildings and structures in the zone of influence of underground construction. Moscow, ASV pp. 168.

- Ilichev VA, Konovalov PA, Nikiforova NS, Bulgakov LA (2004) Deformations of the retaining structures upon deep excavations in Moscow. Proc. Of Fifth Int. Conf on Case Histories in Geotechnical Engineering. New York, USA pp. 5–24.

- Sokolov N, Ezhov S, Ezhova S (2017) Preserving the natural landscape on the construction site for sustainable ecosystem. Journal of applied engineering science 15(4): 518–523.

- Nikiforova NS, Vnukov DA (2011) Geotechnical cut-off diaphragms for built-up area protection in urban underground development. The pros, of the 7thI nt. Symp. «Geotechnical aspects of underground construction in soft ground. tc28 IS Roma, AGI, pp. 157NIK.

- Nikiforova NS, Vnukov DA (2004) The use of cut off of different types as a protection measure for existing buildings at the nearby underground pipeline’s installation. Proc. of Int. Geotech. Conf. dedicated to the Year of Russia in Kazakhstan. Almaty, Kazakhstan pp. 338–342.

- Petrukhin VP, Shuljatjev OA, Mozgacheva OA (2003) Effect of geotechnical work on settlement of surrounding buildings at underground construction. Proceedings of the 13th European Conference on Soil Mechanics and Geotechnical Engineering. Prague.

- Sokolov NS (2016) Technological methods of boring injection piles with multi-place widenings. 10: 54–57.

- Sokolov NS (2019) Technology of increasing the bearing ability of the foundation 6: 67–72.

- Sokolov NS, Sokolov AN, Sokolov SN, Glushkov VE, Glushkov AV (2017) Calculation of bored injection piles of ERT of increased bearing capacity. 11: 20–25.

- Nikonorova IV, Sokolov NS (2017) Construction and territorial development of the landslide slopes of the Cheboksary reservoir. 9: 13–19.

- Sokolov NS, Sokolov SN, Sokolov AN (2023) Technology of the Monolith Reinforced Concrete Rostwerk in Confined Conditions of a Functioning Object. 7: 12–16.

- Sokolov NS, Sokolov SN, Sokolov AN (2023) Practice of construction in special confined conditions. 9: 41–47.

- Sokolov NS, Sokolov SN, Sokolov AN (2023) Geotechnical technology of construction of engineering structures. p. 11.

- Sokolov NS, Viktorova SS, Fedorova TG (2014) Novoe v arkhitekture, proektirovanii stroitel'nykh konstruktsii i rekonstruktsiya : Materialy VIII Vserossiyskoy (II Mezhdunarodnoy) konferentsii, Cheboksary, 20–21 noyabrya 2014 goda / Editorial board: N.S. Sokolov (guest editor), D.L. Kuzmin (responsible secretary), A.N. Plotnikov, L.A. Sakmarova, A.G. Lukin, V.F. Bogdanov, V.I. Tarasov. – Cheboksary: Chuvash State University named after I.N. Ulyanov pp, 411-415.

- Sokolov NS, Petrov MV, Ivanov VA (2014) Novoe v arkhitekture, proektirovaniye stroitel'nykh konstruktsii i rekonstruktsiya: Materialy VIII Vserossiyskoy (II Mezhdunarodnoy) konferentsii, Cheboksary, 20–21 noyabrya 2014 goda [New in architecture, design of construction structures and reconstruction: Materials of the VIII All-Russian (II International) Conference, Cheboksary, 20–21 November 2014] / Editorial Board: N.S. Sokolov (guest editor), D.L. Kuzmin (responsible secretary), A.N. Plotnikov, L.A. Sakmarova, G. Lukin, V.F. Bogdanov, V.I. Tarasov. – Cheboksary: Chuvash State University named after I.N. Ulyanov pp. 415-420.

- Sokolov NN, Sokolov SN, Sokolov AN (2017) Fine-grained concrete as a structural construction material of bored injection piles / ERT N. S. S. Sokolov, S. N. Sokolov, A. N. Sokolov // Stroitel'nye materialy [Construction materials] 5: 16-19.

- Utility model patent No. 161650 U1 Russian Federation, IPC E02D 5/34, E02D 5/44. Device for camouflage widening of the rammed structure in the ground: No. 2015126316/03: declared. 01.07.2015: publ. 27.04.2016 / N. S. Sokolov, Kh. A. Dzhantimirov, M. V. Kuzmin [et al.]; Applicant: Federal State Budgetary Educational Institution of Higher Professional Education "Chuvash State University named after I.N. Ulyanov".

-

Sokolov Sergey Nikolaevich*. Geotechnical Practice of Strengthening the Foundation Base of a Three-Storey Administrative Building. Cur Trends Civil & Struct Eng. 11(1): 2024. CTCSE.MS.ID.000752.

-

Geotechnical Practice; Three-Storey Administrative Building; Foundation Base; Iris Publishers; Iris Publishers Group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.