Review Article

Review Article

Application of Nano-Additives Reinforcement towards Concrete with Excellent Mechanical Properties: A Review

Xi Chen, College of Tourism & Landscape Architecture, Guilin university of technology, China.

Received Date: September 13, 2022; Published Date: October 11, 2022

Abstract

Until the last decade, extensive scientific research has been conducted on the different applications of nanoparticles in civil infrastructures. Nanoparticles are defined as ultrafine particles ranging in dimension below 100 nanometers. The addition of nanoparticles is a promising approach for increasing the concrete’s strength and durability, hence enhancing the concrete’s quality and promoting sustainability. In this literature study, the review focuses on commonly used nanoparticles in different categories, such as carbon nanotube (CNT), graphene (GNP), nano silica (NS), nano Al2O3, nano TiO2, and nano clay. The review highlights the mixing method and the influence of nanoparticles on fresh and hardened concrete properties.

Keywords:High-performance concrete; Nanoparticle modification; Mechanical properties; Fresh and hardened properties

Introduction

Most nations base their economic growth on the infrastructure they have in place. Infrastructure includes things like buildings, bridges, and other infrastructures. When the economy increase, concrete is increasingly needed as infrastructure demand rises, especially high-performance concrete. The concrete mix contains cement, aggregates, sand, water, and any other additives required by design, and the current trend is to improve concrete performance by incorporating additives [1]. Currently, because of the unique physical and chemical characteristics of nanoparticles, nanotechnology presents prospective chances to develop better materials with increased qualities [2]. Nanoparticle-reinforced composites outperformed the ones with microparticles or largersized particles in many research fields, but the fabrication cost limited the large-scale application. Until recently, as the technology improved, the fabrication of nanoparticles became cheaper, creating a great opportunity to develop high-performance concrete by adding nanoparticles. Therefore, with growing demand to concrete with improved mechanical properties, nanoparticle reinforcement is an alternative with great potential.

Studies have shown that adding nanotechnology to the cementitious matrix can improve the properties of concrete. The term “nanoparticle” refers to particles that are 200 nm or smaller, and these substances are added to cementitious matrix either by dry mixing or by dispersing nanoparticles in water prior to wet mixing [3]. In comparison to cementitious composites without nanoparticles, cementitious composites with nanoparticles considerably enhanced microstructure and other mechanical properties. Adding various nanoparticles with proper concentrations to concrete can improve mechanical strength, chemical resistance, and lessen shrinkage while reducing bleeding and segregation. The dispersion of nanoparticles in cementitious composites, which can be accomplished by optimizing the mixing process, is one important component that affects performance [3]. In addition to dispersion, the amount of nanoparticles in the concrete mixture is also a critical factor affecting the performance. If nanomaterials are not dispersed uniformly, agglomerates of nanomaterials tend to develop, and the strength and durability of the concrete will diminish. Typically, less than 10% of nanomaterials are added in most of the studies. Also, the type of nanoparticles can significantly affect the performance of the concrete composite. To discover the optimal reinforcement, it is necessary to experiment with various types of nanomaterial with different concentrations [3]. Therefore, to develop high-performance concrete for the civil infrastructures, it is necessary to summarize the current research of nanoparticle reinforced concrete composites. To fulfill this need, this review incorporates contemporary research on the impact of nanomaterial incorporation on the mechanical strength, durability, and workability of cement-based composites. The discussion in this paper is focused on the commonly used nanoparticles and the effect of dosage on their reinforced properties.

Discussion

Commonly used nano-additives

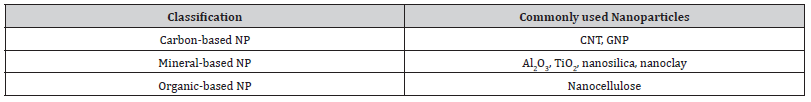

This section focuses on nanoparticle categories and commonly used ones in the concrete mixture. The first way to classify nanoparticles is by dimensions; nanofillers can be classified as 0, 1, or 2-D materials when there are 0, 1, or 2 dimensions greater than 100 nm. Zero-dimensional nanoparticles have been suggested additives that can effectively act as filler, improving impermeability, and filling voids in the concrete mix, leading to an improved mechanical strength; some typically used 0-D nanoparticles are nano-silica and nano-alumina [4]. On the other hand, Onedimensional and two-dimensional particles can also contribute to compressive strength by decreasing porosity and redistributing pores, as well as frost resistance via the mechanism of crack bridging [4]. Materials can also classify the nanoparticle; first, there are carbon-based nanoparticles, which contain carbon atoms only. Then there are organic-based materials, consisting of organic matter; the other is mineral-based materials, such as metals and oxides. The typically used nanoparticles are presented in Table 1 (Table 1).

Table 1:Commonly used nanoparticles in different categories..

Mixing method for nanoparticle/concrete composite

Dispersion is one of the most critical factors affecting the performance of nanocomposite and achieving uniform dispersion of the nanoparticles in the composite matrix has been challenging for researchers. The nanoparticles’ dispersion level significantly impacts the concrete’s fresh and hardened properties. Generally, there are two approaches to disperse nanoparticle concrete mixtures: dry mixing with cement or dispersion in water [3]. In the dry mixing process, nanoparticles should be appropriately dispersed into cement powder by using stationary blades and a rotating drum. Then the mixed powder can be directly used to fabricate concrete composite with water, sand, aggregates, or other admixtures [3]. In the wet mixing process, the nanopowder were pre-dispersed in water using ultrasonication, with or without a chemical dispersant; in addition, more than one type of nanoparticles can be pre-dispersed in water.

Suggested amount of nanoparticles

Researchers point out that the amount of nanoparticles should be controlled within 0.1–10% of cement weight, increasing mechanical properties in concrete composites [5]. With increasing nanoparticle dosage, the likelihood of agglomeration increased, resulting in a dramatic decrease in the performance of the concrete. Researchers pointed out that the agglomerate could reach to millimeter level in the mixture with a high concentration of nanoparticles [5]. Many studies have pointed out that optimum reinforcement can be achieved by 2% or nanoparticles, which avoid aggregation that negatively affects the mechanical properties [3].

Workability of nanoparticle/concrete composite

The addition of nanoparticles could improve or decrease the workability, depending on the type of nanoparticles. Due to their high surface area, nanoparticles absorb a huge amounts of water in certain instances, causing the fresh concrete mixture less workable. However, this property can be beneficial for some specialized applications, and where the greater cohesiveness of nanomodified concrete could avoid segregation [5]. In some instances, the inclusion of nanoparticles may increase the air content of the concrete, which may improve its workability. Another benefit is increased resistance to damage from freezing and thawing cycles. However, the strength may decrease when the air content is high. If the effects of nanoparticles on air entrainment can be well understood and predicted, this property might be used to adjust the air content of concrete, depending on the application demand. Research found that the workability of concrete improves by adding nano Silica, and nano clay [5]. Mudasir et al. mentioned that CNTs caused a drastic decrease in workability, which the slump flow diameter reduced from100 mm to 65 mm [6].

Mechanical Properties of nanoparticle/concrete composite

Nanoparticles increase the strength of cement-based materials by 1) enhancing the hydration process of cement, 2) increasing binder force, 3) modifying the structure of cement paste, and 4) increasing the mixture’s density [7]. The following discussion is the effect of nanoparticles on the strength of concrete composites.

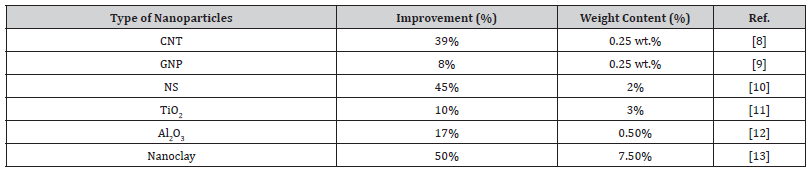

Compressive strength: Compressive strength is one of the most critical properties of concrete, since it ensures the quality of concrete constructions. This section discusses the effect of adding properly dispersed nanoparticles on the concrete’s compressive strength. The compressive strength of concrete mixtures is affected differently by varied types of nanoparticles, and it is possible to attain the optimal compressive strength of the concrete by modifying the nanoparticle concentration [7]. In general, in most instances, the greatest strength was achieved at a lower nanoparticle level, with 1% or 2% nanoparticle content. In addition, numerous studies indicate that compressive strength might improve by above 20% at the age of 28 days [5]. In Table 2, selected studies on the compressive strength of nanoparticle/concrete are presented (Table 2).

Table 2:Influence of nanoparticles on compressive strength.

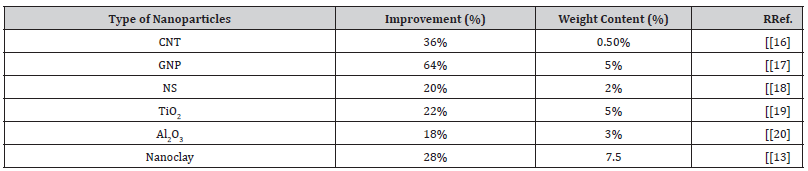

Splitting Tensile strength: The improved split tensile strength can also be achieved by the incorporation of nanoparticles, as well as compressive strength. Similar to the compressive strength, the tensile strength will grow as the concentration of nanoparticles increases; however, once the weight content of nanoparticles exceeds a specific value, the tensile strength will be degraded. The inclusion of nanoparticles has been demonstrated to boost tensile strength by as much as 80 percent, according to the findings of numerous studies [14,15]. Furthermore, investigations on the splitting tensile strength are presented in Table 3 (Table 3).

Table 3:Influence of nanoparticles on splitting tensile strength.

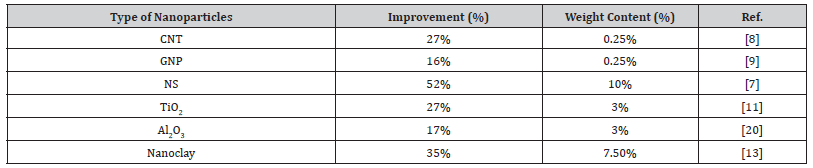

Flexural Strength: Researchers have found that the at the flexural strength of concrete can also be significantly improved by incorporating nanoparticles, and a maximum improvement of around 60% was found in Yehia’s work [21]. On the other hand, the flexural strength improved by 40-50% were commonly achieved by other studies [7,15], and some other studies are presented in Table 4 (Table 4).

Table 4:Influence of nanoparticles on flexural strength.

Shrinkage of nanoparticle/concrete composite

Concrete shrinks when exposed to relative humidity levels below 100 percent and consequently loses water, leading to cracks developed at the early age of service [22]. It is clear that varied nanomaterials affect the mixture’s drying shrinkage. The development of shrinkage in cement paste is proportional to the number of pores with a diameter of less than 20 nm in the matrix at early ages; thus, a greater number of small pores in a cementitious system results in more significant autogenous shrinkage at early ages. The inclusion of nanoparticles reduces the pores’ size, reducing the capillary strains and autogenous shrinkage [15]. In this case, researchers have found the largest reduction in early age shrinkage can reach above 50% with the addition of nanoparticles [23]. Many researchers found that the addition of nanoparticles can increase the shrinkage of the concrete, for example, Chen et al. found that the shrinkage strain increased 32% compared to the reference [24]. In addition, increased shrinkage also found in the concrete composite with CNT, TiO2, Al2O3, and nanosilica. However, studies pointed out that shrinkage in nanoparticle/concrete may vary with different sample mix, one investigation indicates that the addition of CNT also reduce the shrinkage of the concrete of 15.0%, and similar finds were obtained is nanosilica/concrete composites [23].

Summary

This work reviews the effect of nanoscale additives on the

workability and mechanical performance of concrete. The influence

of nanoparticle types and concentration on the performance of

concrete mixture was discussed, and the summaries are presented

below:

1. Depending on the type of nanoparticles, the incorporation

of nanoparticles could either increase or decrease the

workability. Due to their large surface area, nanoparticles can

absorb large quantities of water, making the fresh concrete

mixture less workable. In some situations, the incorporation

of nanoparticles may increase the concrete’s air content, so

enhancing its workability.

2. Nanoparticles increase the strength of cement-based materials

by several ways: i) enhancing the hydration process of cement,

ii) increasing binder force, iii) modifying the structure of

cement paste, and iv) increasing the mixture’s density.

Based on the literature, significantly improved compressive

strength was observed in NS, CNT, TiO2 samples, and CNT,

TiO2, and nanoclay have strong reinforcement on flexural

strength; at last, GNP, TiO2, Al2O3, nanoclay, NS can be very

beneficial to increase the splitting tensile strength. Most of the

nanoparticles will increase the strength and start to decrease

when the concentration of nanoparticles is too high and

forming agglomeration.

3. Despite the excellent improvement in strength, the

incorporation of nanoparticles could lead to increased

shrinkage, which makes concrete more vulnerable to tensile

cracking. However, with proper design, the addition of CNT, NS,

nanoclay, Al2O3 can reduce the shrinkage of the concrete.

Acknowledgment

None.

Conflict of Interest

No conflict of interest.

References

- Vishwakarma V, Ramachandran D (2018) Green Concrete Mix Using Solid Waste and Nanoparticles as Alternatives–A Review. Construction and Building Materials 162: 96–103.

- Mohajerani A, Burnett L, Smith JV, Kurmus H, Milas J, et al. (2019) Nanoparticles in Construction Materials and Other Applications, and Implications of Nanoparticle Use. Materials, 12: 3052.

- Adithya S, Sachin K, Meda US (2021) Review on the Correlation between Mixing, Microstructure and Strength of Cementitious Products with Nanoparticles. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing 822: 012005.

- Ebrahimi K, Daiezadeh MJ, Zakertabrizi M, Zahmatkesh F, Korayem AH (2018) A Review of the Impact of Micro-and Nanoparticles on Freeze-Thaw Durability of Hardened Concrete: Mechanism Perspective. Construction and Building Materials, 186: 1105–1113.

- Reches Y (2018) Nanoparticles as Concrete Additives: Review and Perspectives. Construction and Building Materials, 175: 483–495.

- Mudasir P, Naqash J (2021) The Effect of Water Cement Ratio on the Characteristics of Multi-Walled Carbon Nanotube Reinforced Concrete. Materials Today: Proceedings 43: 3852–3855.

- Chen Y (2018) A Review on the Effects of Nanoparticles on Properties of Self-Compacting Concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing, 452: 022134.

- Ruan Y, Han B, Yu X, Zhang W, Wang D (2018) Carbon Nanotubes Reinforced Reactive Powder Concrete. Composites Part A: Applied Science and Manufacturing 112: 371–382.

- Tao J, Wang X, Wang Z, Zeng Q (2019) Graphene Nanoplatelets as an Effective Additive to Tune the Microstructures and Piezoresistive Properties of Cement-Based Composites. Construction and Building Materials 209: 665–678.

- Supit SWM, Shaikh FUA (2015) Durability Properties of High-Volume Fly Ash Concrete Containing Nano- Silica. Materials and structures, 48: 2431–2445.

- Wang L, Zhang H, Gao Y (2018) Effect of TiO2 Nanoparticles on Physical and Mechanical Properties of Cement at Low Temperatures. Advances in materials science and engineering.

- Muzenski S, Flores-Vivian I, Sobolev K (2019) Ultra-High Strength Cement-Based Composites Designed with Aluminum Oxide Nanofibers. Construction and Building Materials 220: 177–186.

- Hamed N, El-Feky M, Kohail M, Nasr ESA (2019) Effect of Nano-Clay de-Agglomeration on Mechanical Properties of Concrete. Construction and Building Materials 205: 245–256.

- Al-Rifaie WN, Ahmed WK (2016) Effect of Nanomaterials in Cement Mortar Characteristics. Journal of Engineering Science and Technology, 11: 1321–1332.

- Paul SC, Van Rooyen AS, van Zijl GP, Petrik LF (2018) Properties of Cement-Based Composites Using Nanoparticles: A Comprehensive Review. Construction and Building Materials, 189: 1019–1034.

- Kumar S, Kolay P, Malla S, Mishra S (2012) Effect of Multiwalled Carbon Nanotubes on Mechanical Strength of Cement Paste. Journal of Materials in Civil Engineering, 24: 84–91.

- Ismail FI, Farhan SA, Husna N, Shafiq N, Wahab MMA, et al. (2021) Influence of Graphene Nanoplatelets on the Compressive and Split Tensile Strengths of Geopolymer Concrete. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing, 945: 012060.

- Garg R, Garg R, Bansal M, Aggarwal Y (2021) Experimental Study on Strength and Microstructure of Mortar in Presence of Micro and Nano-Silica. Materials Today: Proceedings, 43: 769–777.

- Sastry KGK, Sahitya P, Ravitheja A (2021) Influence of Nano TiO2 on Strength and Durability Properties of Geopolymer Concrete. Materials Today: Proceedings 45: 1017–1025.

- Meddah M, Praveenkumar T, Vijayalakshmi M, Manigandan S, Arunachalam R (2020) Mechanical and Microstructural Characterization of Rice Husk Ash and Al2O3 Nanoparticles Modified Cement Concrete. Construction and Building Materials 255: 119358.

- Yehia S (2013) Effect of Nano-Clay on the Mechanical Properties of Fresh and Hardened Cement Mortar Comparing with Nano-Silica. In Proceedings of the Proceedings of the Second International Conference on Materials, Energy and Environments (ICMEE), Yokohama, Japan, pp.8–9.

- Wang B, Yan L, Fu Q, Kasal B (2021) A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resources, Conservation and Recycling, 171: 105565.

- Hawreen A, Bogas J (2019) Creep, Shrinkage and Mechanical Properties of Concrete Reinforced with Different Types of Carbon Nanotubes. Construction and Building Materials, 198: 70–81.

- Chen Z, Xu Y, Hua J, Wang X, Huang L, et al. (2020) Mechanical Properties and Shrinkage Behavior of Concrete-Containing Graphene-Oxide Nanosheets. Materials, 13: 590.

-

Xi Chen*. Application of Nano-Additives Reinforcement towards Concrete with Excellent Mechanical Properties: A Review. Cur Trends Civil & Struct Eng. 9(2): 2022. CTCSE.MS.ID.000707.

-

Building, Environment, Curtainwall, Earthquake, Structural engineer, Geometric

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.