Review article

Review article

Wind Over Water: Unraveling The Potential of Offshore Wind Energy

Muhammad Ahmad1*, Iram Rehman2

1Department of Aerospace Engineering, College of Aeronautical Engineering, National University of Sciences and Technology, Islamabad, Pakistan

2Bahauddin Zakariya University, Multan, Pakistan

Muhammad Ahmad, Department of Aerospace Engineering, College of Aeronautical Engineering, National University of Sciences and Technology, Islamabad, Pakistan

Received Date:October 15, 2024; Published Date:November 11, 2024

Abstract

Offshore wind energy has emerged as a key player in the global renewable energy landscape, offering vast untapped potential for sustainable electricity generation. This review paper provides a comprehensive overview of offshore wind energy harvesting, encompassing its historical evolution, current status, and future prospects. It delves into the importance and growth of offshore wind energy, highlighting its significant contributions to global renewable energy targets. The paper examines methods for offshore wind resource assessment and explores the regional variability and considerations that influence offshore wind potential. Technological advancements in offshore wind turbines, including floating wind turbines, vertical axis wind turbine, and blade and rotor design innovations, are discussed, along with their implications for future developments. Environmental impact assessment of offshore wind farms is examined, focusing on ecological effects, marine wildlife concerns, and mitigation measures. The optimization of offshore wind farm layout, operation, and maintenance strategies is addressed, emphasizing the importance of grid integration and compliance requirements. Finally, the paper identifies challenges and future prospects in offshore wind energy harvesting, including deepwater deployment challenges, technological innovation needs, and potential solutions and research directions.

Keywords:Offshore wind energy; wind resource; fixed offshore; floating offshore; environmental impact; wind farm

Abbreviation:CFD: Computational Fluid Dynamics; CAWT: Cross-Axis Wind Turbines; FOWT: Floating Offshore Wind Turbine; FEPA: Foreign Extortion Prevention Act; GW: Gigawatts; HAWT: Horizontal Axis Wind Turbine; LCOE: Levelized Cost of Energy; LiDAR: Light Detection and Ranging; MRWT: Multirotor Wind Turbine; OWFs: Offshore Wind Farms; TLP: Tension Leg Platforms; UAV: Unmanned Aerial Vehicle; VAWT: Vertical Axis wind Turbine; WPD: Wind Power Density

Introduction

Currently, the electricity market primarily relies on conventional energy technologies, with hydropower also playing a significant role. However, some of these technologies have faced crises. Initially, fossil fuel-based technologies encountered challenges, notably during the oil crises of 1973 and 1979. Subsequently, nuclear energy, particularly fission, also faced crises, albeit not as widespread as fossil fuels, with opposition varying by country and policy factors. Furthermore, hydropower experienced a crisis due to environmental concerns stemming from a lack of conservation measures for hydrological resources. This led to halting classic large hydropower projects and stalling the development of smallscale hydropower initiatives [1-3]. Ocean energy aims to contribute significantly to the world’s energy supply in order to replicate wind energy’s success. But it is easier said than done to accomplish this aim. Ocean energy comes from a variety of sources, including temperature variations, salinity gradients, waves, currents, and tides. Tidal energy has proven to be the most advanced of them.

Despite this, there are still few installations and a low worldwide output of tidal energy electricity because of serious economic and environmental issues [4,5]. Ocean energy thus contributes nothing appreciable to the world’s energy mix at this time. Despite being a more well-established technology than other ocean energy sources, tidal energy’s total utilization is still rather low. The main emphasis of efforts has been to leverage big bodies of water’s surface wave and tidal motion for electricity [6]. The history of offshore wind energy harvesting is extensive, going all the way back to the early 1900s, when the Vindeby wind farm was established with the installation of the first offshore wind turbine off the Danish coast in 1991. Since then, a growing worldwide interest in renewable energy sources and technology breakthroughs have caused a substantial evolution in the offshore wind business. Because of its enormous potential and advantages for the environment, offshore wind energy is becoming a key element of global renewable energy plans [6,7]. Wind energy, recognized as a crucial renewable source, initially focused on onshore wind farms, with only 2000 megawatts (MW) of offshore capacity by 2009.

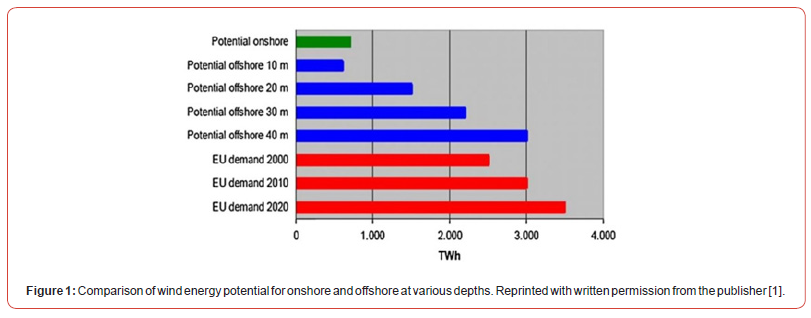

The first offshore wind turbine, a 220-kW unit, was installed off the Swedish coast in 1990, supported by a tripod structure in 6-meter-deep waters, 350 meters from shore. From 1991 to 1998, experimental projects tested turbines of 450-600 kW capacity, up to 4 km offshore and 6 meters deep, proving profitable and reliable. Subsequently, commercial wind farms including Blyth, Middelgrunden, and Yttre Stengrund were built, and multimegawatt turbines were introduced. One example of this is the Utgrunden project in Sweden (2000). Ongoing projects such as Horns Rev and Nysted in Denmark validated the feasibility of offshore wind turbines [1,8]. The imperative to expand offshore wind, evident in Figure 1, aligns with Kyoto protocol commitments. Offshore wind growth varies by country due to factors like land constraints, environmental impact, and government support. For instance, countries like the Netherlands lack land space, driving UK and Danish preferences for offshore due to onshore opposition.

Offshore wind farms, an increasingly part of coastal landscapes, require comprehensive management for technical, financial, and environmental sustainability [9,10]. In areas where wind is present, waves often accompany it, suggesting the potential integration of wave energy harvesters alongside wind turbine structures. Among various wave energy harvesting devices, one particularly promising option is a cylindrical structure employing Wells turbines as shown in Figure 2. This choice is especially suitable given the additional offshore applications such as uranium harvesting and aquaculture. The circular system, illustrated in the diagram, could be constructed from bolted together sections and installed around the wind tower’s base. During severe storms, it could be submerged to prevent damage. An estimate of the combined power output from this wave power generation ring is provided in the same diagram. Notably, this output is nearly equivalent to that of the wind turbine itself. It’s important to acknowledge that while wind typically accompanies waves, significant ocean swells can persist even in periods of slow wind, often traveling vast distance [7].

Importance and Growth of Offshore Wind Energy

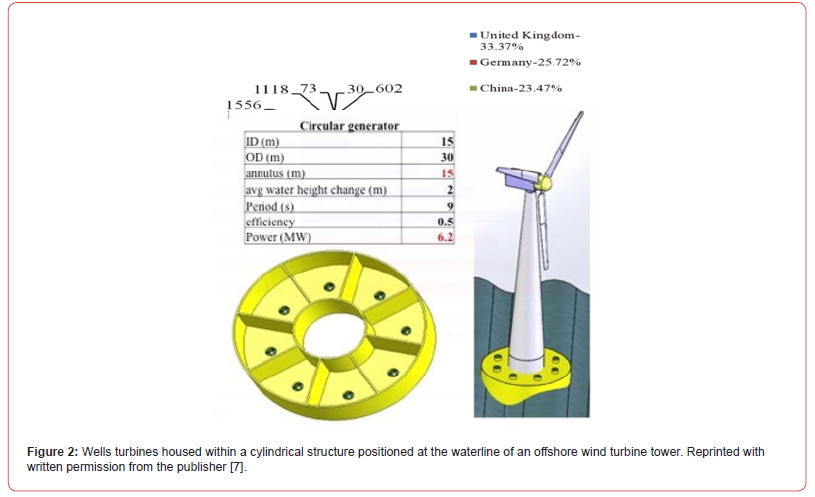

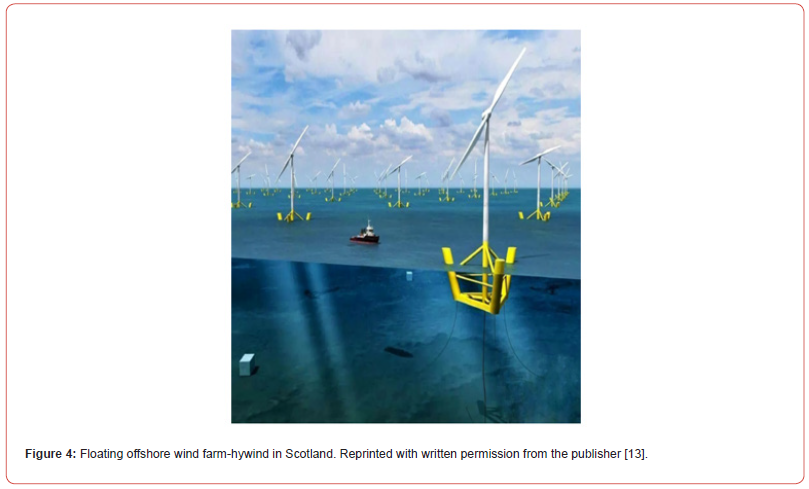

The importance of offshore wind energy has been underscored by its remarkable growth trajectory. Installations have surged globally, with the cumulative offshore wind capacity reaching over 35 gigawatts (GW), a significant increase from just 0.5 GW in 2003. This growth can be attributed to various factors, including increasing energy demand, declining costs of offshore wind technology, and ambitious renewable energy targets set by governments around the world. Furthermore, offshore wind energy offers several advantages over its onshore counterpart, including higher wind speeds, reduced visual and noise impacts, and greater space availability for installations [11,12]. Previous research indicates that offshore wind energy becomes economically viable when wind speeds surpass 7 m/s. Onshore wind power has far lower development costs than offshore wind power, which can be as much as twice as much. About 15% of the overall cost of developing offshore wind power is made up of installation costs alone. OWFs generate 20% to 40% more electricity than onshore wind turbines because they capture wind energy more effectively in spite of these difficulties. According to the annual report of the global wind energy council, the installed capacity of wind energy globally doubles every three years, and this growth rate is expected to continue for the foreseeable future. Figure 3 illustrates the dominating worldwide position of offshore wind energy in European nations among various energy advances. The first largescale commercial floating offshore wind power plant was launched in 2017; Figure 4 depicts the Hywind Scotland floating wind farm [13-15].

Offshore Wind Resource Assessment and Potential

Methods for Resource Assessment

The evaluation of wind resources is a crucial phase in the development of a community wind project, as it provides the groundwork for determining the project’s initial viability. Interest in small-scale wind turbine installations has grown as technological developments in wind turbines continue to improve affordability. Identifying installation sites abundant in wind resources is essential to maximize the efficiency and productivity of wind turbines. By pinpointing areas with optimal wind conditions, developers can ensure the successful implementation and operation of wind energy projects, contributing to sustainable energy solutions and environmental stewardship [16].

The evaluation of offshore wind resources is essential to establishing the profitability and feasibility of offshore wind energy projects. A variety of techniques are used to evaluate resources, including meteorological information gathered from offshore buoys and met towers, satellite-based wind speed measurements, and remote sensing technologies like light detection and ranging (LiDAR). These techniques offer insightful information on wind direction, speed, and turbulence properties—all crucial for optimizing turbine design and choosing the best location [16,17]. The wind power density (WPD), which is determined using the equation in Equation 1, is frequently used in the assessment of wind energy resources.

where WH is the wind speed at a chosen hub height (usually 120 meters), and ρa is the air density (1.225 kg/m3 at 288.15 K). Global warming may cause variations in air density, but these will have little effect on WPD. For example, a substantial rise of 5 K would only cause the WPD to drop by only 1%.

Furthermore, advancements in wind turbine technology are expected to enhance efficiency and parameters like cut-in and cutout velocities in the coming decades [18]. However, predicting these improvements is challenging. WPD is favored as the primary metric for offshore wind energy resource assessment due to its reliability and independence from turbine power curves. It also facilitates comparisons between different regions to identify areas with the highest wind energy potential [19,20].

Global Offshore Wind Potential

On a global scale, the offshore wind potential is substantial, with vast untapped resources awaiting exploration.

According to estimates, the technical potential for offshore wind energy exceeds 18,000 GW, significantly surpassing current global electricity demand. This underscores the immense opportunity for offshore wind to contribute significantly to the world’s energy mix and mitigate greenhouse gas emissions. Nonetheless, there is a great deal of regional variation in the offshore wind potential, which is determined by bathymetry, wind patterns, and the proximity of coastal settlements. The potential for offshore wind growth is especially great in areas with favorable offshore wind conditions, such as the North Sea and the US Atlantic coast. On the other hand, regions with deep oceans or little wind resources can have a harder time efficiently using offshore wind energy [19]. In comparison to the last two decades, it is anticipated that the expansion of offshore wind generating capacity would pick up speed due to the commissioning of floating wind units, technological breakthroughs, significant growth, and turbine upgrades. There are now 35 GW of installed offshore wind power capacity. This amount is predicted to reach over 382 GW by 2030 and to skyrocket to nearly 2002 GW by 2050 [21].

The creation and functioning of OWFs can be impacted by environmental, social, and regulatory aspects, which are also included in the regional perspective. Stakeholder participation is critical to addressing community concerns and achieving project approval, while environmental evaluations are critical to analyzing possible impacts on marine ecosystems, animal habitats, and protected species. Moreover, different nations have different regulatory frameworks that have an impact on offshore wind projects’ viability and profitability. These frameworks range in terms of approval procedures, grid connection requirements, and incentive programmes. Successful offshore wind energy deployment and well-informed decision-making depend on an understanding of these geographical variances and factors.

Technological Advancements in Off-Shore Wind Turbines

Evolution of Offshore Wind Turbine Technology

Considerable progress has been made in offshore wind turbine technology over the years with the goal of improving cost effectiveness, dependability, and efficiency. At first, onshore designs were modified to accommodate offshore wind turbines’ resistance to maritime conditions. But as time has gone on, specialized offshore turbine designs have appeared, bringing with them advances catered to the special opportunities and difficulties that OWFs provide [22]. With its ability to produce electricity at a gigawatt scale swiftly, its high energy yield per square meter, and its advantageous location in broad, calm oceans, and offshore wind energy is a particularly appealing solution for efficiently powering coastal regions with high population densities. Advances in operating procedures, foundations, access tactics, installation techniques, system integration, and turbine technologies have allowed for the expansion of offshore energy projects into deeper seas and farther offshore regions with significant energy potential.

Conventional fixed base offshore wind turbines are often erected in waters as deep as 40 meters, while some can be found as far out from the coast as 80 km and as deep as 60 meters. On the other hand, installations in waters deeper than 60 meters are possible with floating foundations. Offshore wind energy technology has improved substantially over the last ten years, making it the most advanced renewable energy source [21,23,24]. A number of factors, such as the technology used, the layout of the wind farms, and fluctuations in the weather at different wind farm locations, affect the capacity factors of wind turbines in offshore wind power plants. The worldwide weighted average capacity factor for yearly installed offshore wind turbines varied from 35% to 45% between 2010 and 2020. The capacity factor for recently launched projects ranged from 33% to 47% in 2020. Greater power gathering capabilities are possessed by wind turbines with wider swept areas and taller hub heights, which improves their capacity factors [21].

After more than thirty years of study and development, offshore wind has become a viable alternative for governments and businesses looking to generate electricity. Working together, European markets and seasoned players have created a strong offshore wind supply chain, especially in areas that border the North and Baltic Seas. Deeper seas now provide more prospects for offshore wind turbines thanks to innovations like floating foundations. The development of bigger turbine technologies, floating foundations, multidimensional structures, integrated power production technologies, and offshore energy centers are some of the major growing themes in offshore wind. By stabilizing wind power output and improving capacity factors, offshore wind becomes more advantageous for electrical systems than onshore wind. Technological improvements focus on increasing turbine capacity factors while reducing costs, achieved through higher hub heights and rotor swept areas. This trend has led to larger rotor sweep areas in the latest offshore turbine models, resulting in more powerful turbines worldwide [22].

Current State-of-the-Art Turbine Designs

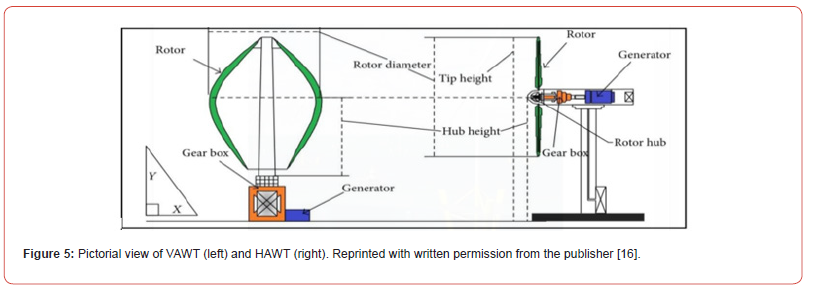

Based on their orientation and design, wind turbines may be divided into two primary categories: Horizontal axis wind turbine (HAWT) and vertical axis wind turbine (VAWT). Because it is more durable and efficient than VAWTs, the HAWT is more popular. As such, HAWTs account for the bulk of large-scale wind turbines [25,26]. Key components of a fundamental wind turbine system configuration include the base, support structure, propeller, central housing, power generator, and spinning blades, depicted in Figure 5. Generators harness electromagnetic induction to produce an electrical voltage, facilitating the transmission of electricity. As the wind rotates the rotor blades, voltage is generated through the relative movement of either the magnets or the conductor. This voltage powers the distribution of electrical current via power lines. The turbine blades deflect the wind, initiating their rotation, which in turn activates the generator to convert wind force into electricity. VAWT present an alternative to traditional HAWTs, offering unique advantages in certain offshore applications. VAWTs feature a vertically oriented rotor shaft and blades that rotate around a central axis, allowing for omnidirectional wind capture and simplified yaw control mechanisms.

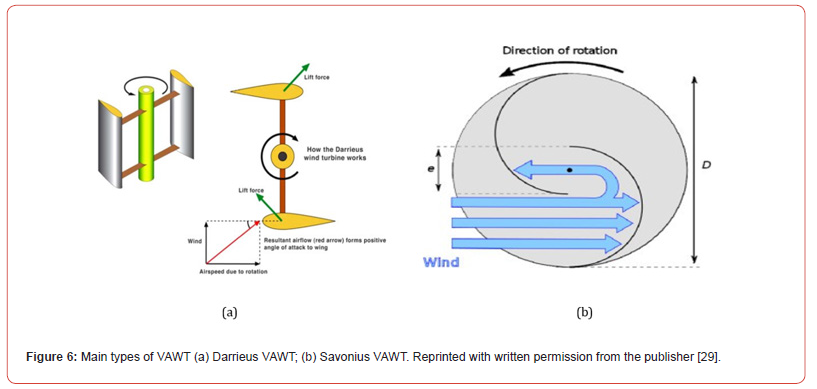

While VAWTs have historically faced challenges related to lower efficiency and increased complexity compared to HAWTs, recent advancements in aerodynamic design and materials have revitalized interest in this technology for offshore wind energy harvesting [25,27]. Typically, VAWTs are classified into two primary types: Savonius-Rotor and Darrieus-Rotor as shown in Figure 6. The Savonius design operates on drag force, akin to the vertical axis windmills historically utilized in Sistan. Similar to HAWTs, they possess a self-starting mechanism [25,28]. Modern turbine designs have a number of important characteristics that set offshore turbines apart from their onshore equivalents. These include powerful systems to prevent corrosion, complex pitch and yaw control mechanisms to operate at peak efficiency in strong winds, and sophisticated monitoring and control systems to facilitate remote maintenance and operation. To maximize energy output and reduce stresses on the structure, offshore turbines also include cutting-edge blade designs, such as swept blades and aerodynamic refinements.

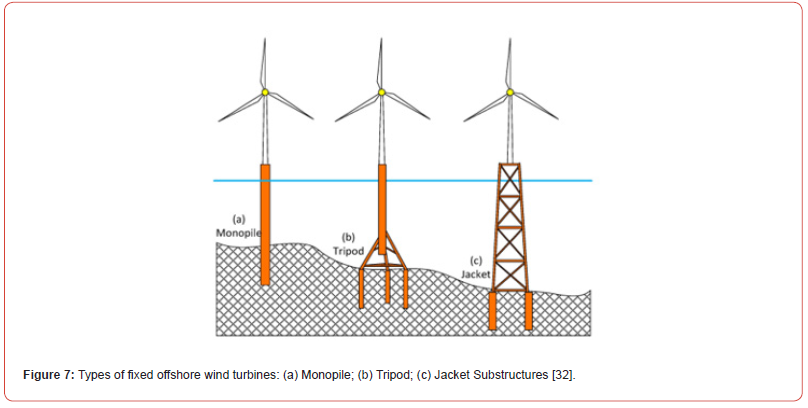

Fixed Offshore Wind Turbines Structures Monopile

The monopile foundation has been the predominant choice for modern offshore wind turbines in recent decades (Figure 7). By the end of 2016, approximately 81% of European offshore wind turbines utilized monopile foundations, including prominent projects like Horns Rev 1–3, Anholt, London Array, and Dantysk. Monopiles are typically employed in shallow waters (<40 meters) and consist of a steel tubular section with diameters ranging from 3 to 6 meters and lengths of 20 to 50 meters, weighing up to 1000 tons. Installation involves pile driving or drilling, typically completed within 24 hours without the need for seabed preparation [30-32].

Tripod

An outgrowth of monopiles, tripod foundations are often used for bigger turbines and deeper seas up to 50 meters. For increased stability, tripods have three-legged bases that are attached to a central steel tube section that is buried 10–20 meters below the seafloor (Figure 7). Installation, requiring special equipment, takes 2–3 days for turbines weighing up to 700 tons. While no seabed preparation is necessary, tripods entail higher construction and maintenance costs, with erosion protection needed in areas with significant currents or sediment erosion [33-35].

Jacket

In deeper waters up to 60 meters, jacket or braced frame substructures are typically employed, akin to those used in oil and gas platforms (Figure 7). Jackets feature lattice truss structures connected to tubular legs driven into the seabed. Installation, feasible at depths of 10–60 meters and extendable to 80 meters, usually takes around three days. Jackets offer resilience to harsh offshore conditions, providing higher resistance to waves and currents compared to monopiles or tripods. However, they entail higher installation and construction costs and are often used as transitional water substructures [36,37].

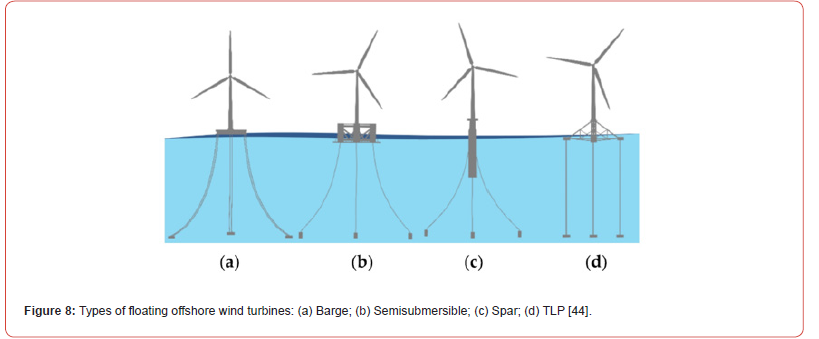

Floating Offshore Wind Turbines

An unprecedented advancement in offshore wind energy technology is represented by floating wind turbines, which make it possible to install turbines in deep oceans where fixed-bottom foundations are not viable. Because these turbines are installed on floating platforms that are secured to the ocean floor, their location may be altered to take advantage of more offshore wind resources. Spar buoy, semi-submersible, and tension-leg platforms are just a few of the designs of floating wind turbines that have been created; each has unique benefits in terms of stability, affordability, and deployment flexibility [38-40].

Spar-Buoy

By positioning the center of gravity sufficiently below the center of buoyancy, the deep-draft vertical cylinder of the spartype platform ensures buoyancy and roll and pitch stability (Figure 8). A catenary or semi-taut spread mooring system made of steel cables, synthetic fiber ropes, and/or chains is used to maintain the station. The hull may be water-ballasted to a vertical position after being floated horizontally and towed while underwater. Except in deep Norwegian fjords, assembly and quayside hull installation are usually impossible because of it considerable draft [41,42]. The most widely tested technology for floating wind turbines is the floating spar-buoy idea, which was used in the first FOWT prototype that was put into service on a large scale by Statoil in Norway in 2009. The Spar-Buoy design is appropriate for water depths beyond 150 meters and is quite inexpensive. Wave forces are lessened by its small volume close to the open surface, and category mooring makes installation simple. Its stability is mostly dependent on buoyancy and weight distribution, though, and it suffers from considerable motion. It also demonstrates notable yaw motion and related torque [43].

Tension Leg Platform

Tension leg platforms (TLPs) are well-known in the oil and gas sector for their capacity to accommodate floating offshore wind turbines (FOWTs). Compared to conventional floating foundations, TLP wind turbines exhibit much reduced heave, pitch, and roll motions (Figure 8). They also have the potential to drastically reduce production costs in deep waters when compared to fixed platforms. The TLP design provides exceptional stability and little motion because of its exceptional torque and yaw motion. When the water is deeper than 50 meters, it performs admirably. However, installation is complex, and manufacturing costs are rather high due to the requirement for expensive anchors and positive tension in tethers [44,45].

Barge

The barge-type FOWT consists of one or more wind turbines mounted on a spacious shallow-draft barge design (Figure 8). Stability is achieved using a huge waterplane area in this design. Similar to the semisubmersible version, the barge-type FOWT can perform quayside assembly and wet towing. Its primary advantage is its simple production method. The barge’s large water-plane area, together with its strong torque and yaw motion, all contribute to its stability and buoyancy. It may be easily placed using ordinary mooring lines at depths more than 50 meters. It does, however, experience enormous motion and wave forces due to its large volume at the free surface. It also has issues with natural frequency and has rather high production costs [45].

Emerging Innovations and Future Trends

Looking ahead, emerging innovations and future trends in offshore wind turbine technology hold the promise of further advancements. Floating wind turbine technology, for instance, offers the potential to access deeper waters and more expansive offshore wind resources [46]. Additionally, there is work underway to produce turbine designs that are tailored for certain offshore environments, such as typhoon-resistant turbines for areas vulnerable to severe weather. Furthermore, advances in materials science such as the use of lightweight composite materials as well as advancements in generator and drivetrain technologies should support the ongoing development of offshore wind turbines, lowering costs and boosting their competitiveness in the market for renewable energy [47,48].

Blade and Rotor Design Innovations

Innovations in rotor and blade design are essential to raising the effectiveness and performance of offshore wind turbines. Improved blade designs allow for decreased structural stresses and increased energy extraction. Examples of these include swept blades with aerodynamic profiles tailored to offshore wind conditions. Variablespeed operation and adaptive pitch control systems, among other rotor designs, further optimize turbine performance under various wind speeds and operating circumstances. Furthermore, advances in materials science such as the application of carbon fiber composites and creative manufacturing processes for blades are propelling advancements in blade longevity, durability, and affordability, which is supporting the continuous advancement of offshore wind turbine technology [49,50]. Blades and rotors equipped with the capability to adjust themselves in response to unpredictable wind conditions such as gusts, turbulent areas, shear, etc., belong to the category of rotor technology.

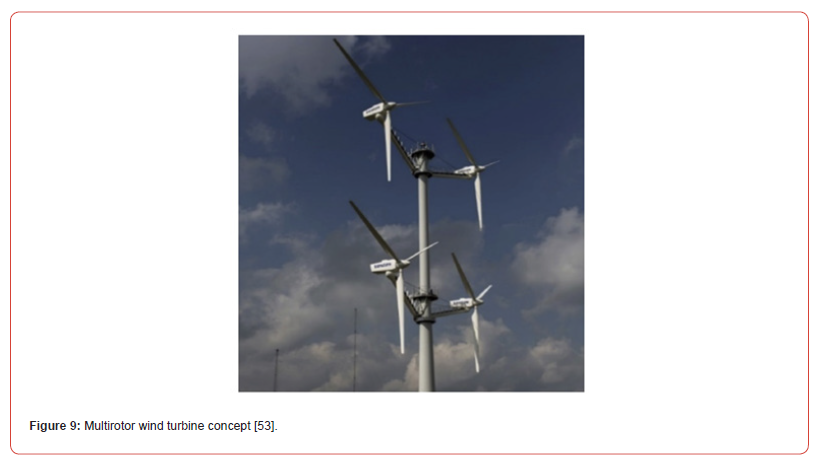

To improve wind turbine capacity factor and save costs, rotor diameters will probably keep growing in the future. Larger rotors, however, come with difficulties since power generation is proportional to the square of the rotor radius, yet the rotor mass grows exponentially with rotor radius. This makes cost control challenging. Large rotor blade manufacturing, shipping, and installation provide additional difficulties. The idea of multirotor wind turbines (MRWT), shown in Figure 9, has come to light as an inventive remedy for these problems. Shorter rotor blades are the product of MRWT, which splits a single-rotor wind turbine’s power output over many rotors [51]. One kind of wind turbine technology called magnetic levitation uses full-permanent magnets to provide a blade lift, which reduces friction. Although this technology is somewhat advanced for low-power operations, it still confronts several difficulties, chiefly related to its high cost and low efficiency [52,53].

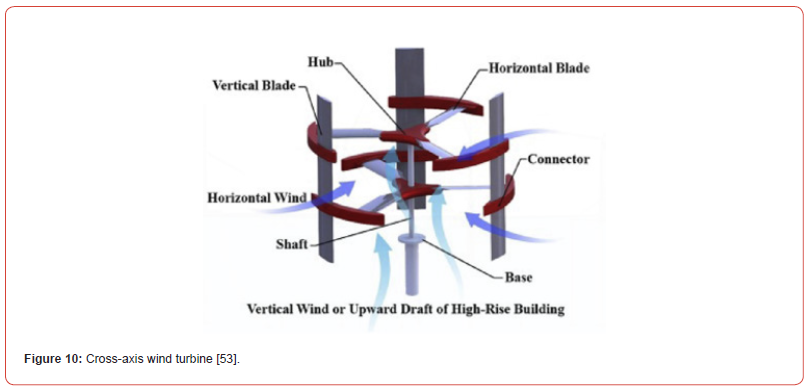

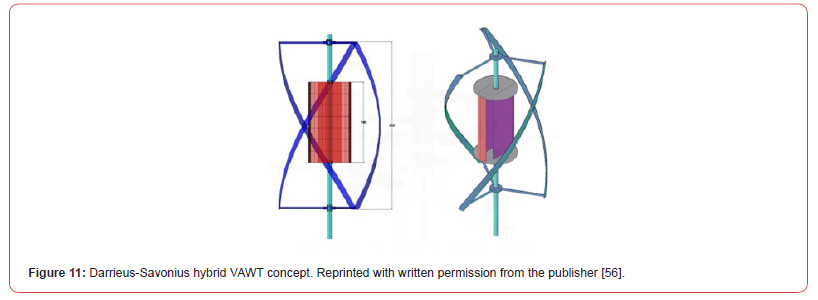

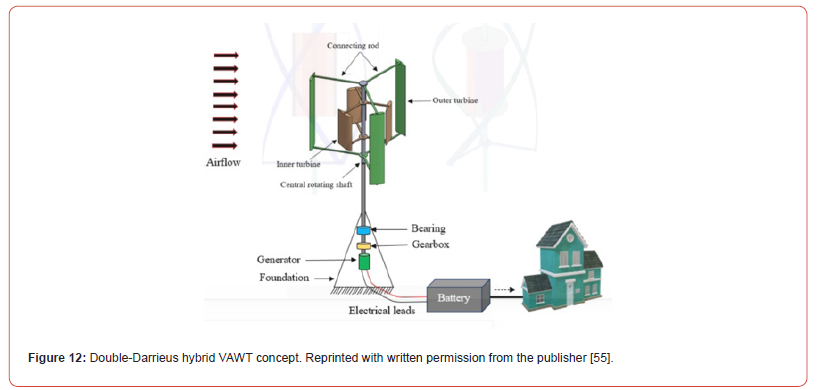

Cross-axis wind turbines (CAWT) are capable of harnessing energy from wind coming from all directions, making them suitable for urban areas (Figure 10). CAWT can achieve a rotational speed of 609 rpm, which is approximately 166% higher than the rotational speed of VAWT, which is 229 rpm. As a result, greater power generating capacity is correlated with faster rotational speed. This technique successfully reduces the disadvantages of HAWT and VAWT [54]. A hybrid VAWT is another example of how cuttingedge design principles and technological advancements have come together to maximize wind energy generation’s performance and efficiency. These turbines are able to catch wind from several directions and adjust to different wind conditions by integrating different rotor topologies, such as Savonius and Darrieus (Figure 11), Double-Darrieus (Figure 12), and mixing vertical and horizontal axis components.

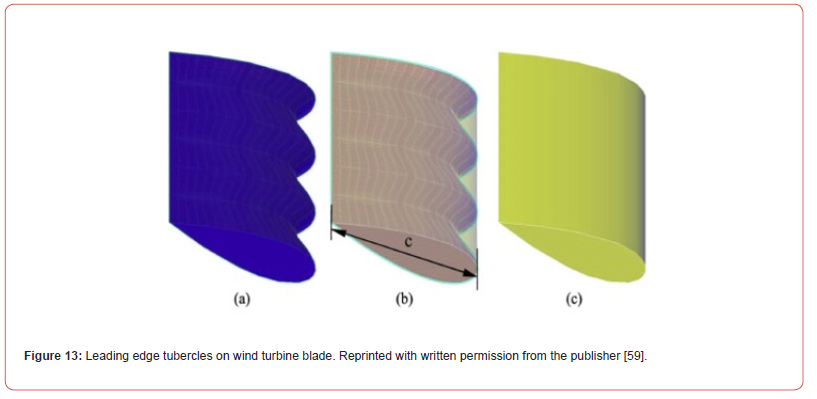

Advanced energy storage and generating systems improve energy capture and utilization even further, while aerodynamic improvements like shrouds or ducts maximize airflow to boost efficiency. Furthermore, real-time changes are made possible by clever control systems, guaranteeing maximum turbine performance. By means of these integration and innovations, hybrid VAWTs present a viable strategy to augment the dependability, efficacy, and aggregate efficiency of wind power generating [55,56]. Leading edge tubercles, or biomimicry, as it is known in wind turbines, are inspired by nature, notably the tubercles on humpback whale fins. Wind turbine blades include tiny protrusions along their leading edges to emulate this natural pattern (Figure 13). These tubercles cause airflow disruption and vortex creation, which delays stall conditions and increases lift. This improves turbine performance at lower wind speeds and lessens the possibility of damage during strong winds. By using biological concepts into engineering design, this biomimetic technique not only increases the efficiency and stability of wind turbines but also advances sustainable energy technology [57,58].

Environmental Impact Assessment of Offshore Wind Farms

Ecological Effects of Offshore Wind Farms

Depending on the bio-geographical context, which includes the natural features and sensitivity of the affected region, ecological hazards resulting from the negative consequences of wind energy devices might vary dramatically. The possible effects of wind energy development are contingent upon several factors, including but not limited to the local animal populations, habitat types, migratory routes, and ecological sensitivity [59]. Therefore, a comprehensive understanding of the unique ecological dynamics of each region is essential for assessing and mitigating risks effectively. Implementing site-specific monitoring, impact assessments, and mitigation measures can help address these challenges and promote sustainable wind energy development that minimizes harm to ecosystems and biodiversity [60]. Marine ecosystems are impacted by OWFs in both beneficial and harmful ecological ways.

Although they help mitigate the effects of climate change by lowering green-house gas emissions, the marine ecosystems may be negatively impacted in several ways during their construction and operation. Changes in water quality, disruption of marine species, and modifications to sediment dynamics are a few of these effects. Comprehending and alleviating these ecological impacts is crucial for the sustainable development of OWFs [61,62]. Global marine management plans are quite optimistic about offshore wind energy growth. Although this holds great promise for the production of renewable energy, it also highlights possible conflicts with conservation interests and other uses of the coastal landscape. Balancing the benefits of renewable energy with the need to preserve marine ecosystems and accommodate various marine activities presents a complex challenge for policymakers and stakeholders alike.

Finding sustainable solutions that address these conflicts and promote responsible development while safeguarding marine biodiversity remains a priority in the advancement of offshore wind energy [63]. Potential effects on marine life and ecosystems are among the main worries about offshore wind projects. Offshore wind turbines can have an impact on marine animals, seabirds, fish, and benthic species through a variety of means, including habitat displacement, collision hazards, and disturbance from building and operation. Benthic habitats can also be altered, and biological processes can be interfered with by the installation of underwater infrastructure, such as cables and foundations. Careful planning, monitoring, and mitigation measure implementation are necessary to protect sensitive species and ecosystems when utilizing offshore wind energy [64-66]. Marine animals and seabirds are at risk from OWFs. Seabirds are especially susceptible to striking OWF pylons or becoming diverted from their usual flight trajectories, which requires them to invest more energy to go around the wind farm.

Because of their keen hearing, cetaceans may be harmed by the loud noises made during OWF construction. Although monitoring data from foreign extortion prevention act (FEPA) reports indicate that post-OWF development seabed dynamics and morphology are not significantly affected, building phases frequently disrupt preexisting processes, increasing turbidity and burying sediment. OWFs can also affect marine ecosystems and fisheries by reducing the amount of fishing grounds that are accessible and causing a shift in the fishing effort. Recently, there have been more and more OWF proposals, which have increased awareness of these issues [67,68].

Mitigation Measures and Best Practices

To minimize the environmental impact of OWFs, various

mitigation measures and best practices can be employed [69-72].

These include:

a) Pre-construction surveys and evaluations to help with

project planning and design by identifying species and habitats

that are sensitive.

b) Establishing exclusion zones and seasonal limitations

to reduce the amount of disruption that construction and

operation cause to marine species.

c) The installation of equipment to discourage birds and

marine mammals from approaching turbines, such as radar

systems and sound deterrents, in order to lower the danger of

collisions.

d) Using noise-cancelling techniques when driving piles and

buildings to reduce noise disruption to fish and marine animals.

e) Putting in place compensatory and habitat restoration

strategies to make up for any inevitable effects on marine

environments.

f) Extended observation and flexible handling to evaluate

the efficiency of mitigating actions and guarantee adherence to

legal mandates.

g) It is feasible to strike a balance between the production

of renewable energy and environmental protection by

implementing these mitigation measures and best practices

into offshore wind farm development. This will ensure the longterm

sustainability of offshore wind energy projects.

Offshore Wind Farm Layout Optimization

Layout Design Principles

The layout of OWFs must be optimized in order to maximize energy output, save expenses, and lessen environmental effects. Principles of layout design take into account things like the distribution of wind resources, ocean depth, seabed characteristics, maritime traffic, and environmental limitations. The objective is to set up wind turbines in a way that minimizes wake effects, interturbine spacing, and cable routing complexity while optimizing energy extraction. Spatial planning strategies, such as grouping turbines to take advantage of favorable wind conditions and aligning rows to reduce wake interference, are frequently included in design concepts [73-75].

Optimization Techniques and Algorithms

The layouts of OWFs are optimized using a range of optimization techniques and algorithms. These include multi objective optimization techniques, heuristic algorithms, and genetic algorithms that iteratively assess and improve layout configurations in accordance with preset goals and limitations [74,76]. Optimization algorithms identify layouts that balance competing goals, such energy output, cost-effectiveness, and mitigating environmental impact. These characteristics include turbine spacing, orientation, and inter-array cable routing. Furthermore, sophisticated computational tools are employed to evaluate layout design performance and improve optimization techniques, such as wake modelling and Computational Fluid Dynamics (CFD) simulations [75,77,78].

Offshore Wind Farm Operation and Maintenance Strategies

Maintenance Challenges and Solutions

Since OWFs are located in distant areas and face logistical hurdles, they provide special operating and maintenance issues. Access issues, corrosion, component wear and tear, and erratic weather are some of the maintenance obstacles. Operators of OWFs use a variety of maintenance techniques, including conditionbased, predictive, and planned maintenance, to solve these issues. Regular component inspections and service are part of scheduled maintenance, which aims to guarantee dependable performance and prevent malfunctions. With condition-based maintenance, maintenance tasks are prioritized according to the actual state of the asset and equipment health is evaluated using real-time monitoring data. Furthermore, to improve the efficiency and safety of maintenance, sophisticated maintenance techniques like robots, drones, and automated inspection instruments are being used more and more [79,80].

Predictive Maintenance Approaches

By using sensor technology, machine learning, and data analytics, predictive maintenance may anticipate equipment faults before they happen, reducing downtime and streamlining maintenance plans. Proactive maintenance activities can be recommended and early warning signals of component deterioration can be found by predictive maintenance algorithms utilizing real-time sensor readings and previous performance data analysis. These approaches enable offshore wind farm operators to transition from reactive maintenance practices to proactive and predictive maintenance strategies, reducing maintenance costs and improving asset reliability [79-82].

Remote Monitoring and Inspection Technologies

Technologies for remote monitoring and inspection are essential to offshore wind farm maintenance because they allow operators to keep an eye on the condition of the equipment, spot irregularities, and conduct inspections without sending workers to the site. In order to provide real-time insights into the operation and condition of assets, remote monitoring systems gather data from sensors mounted on wind turbines, substations, and support structures. This data is analyzed by sophisticated analytics tools to find patterns, pinpoint problems, and improve maintenance plans. Similar to this, visual inspections of offshore assets, such as foundations, turbine blades, and subsea cables, are made possible by remote inspection technologies like drones, remotely operated vehicles, and unmanned aerial vehicles (UAVs), which eliminate the need for expensive and time-consuming manual inspections. Offshore wind farm operators may increase maintenance efficiency, decrease downtime, and improve overall asset performance by using remote monitoring and inspection technology [81,82].

Integration of Offshore Wind Energy into The Grid

Grid Connection Infrastructure

Strong grid connection infrastructure is needed to transfer power produced offshore to onshore substations and eventually to customers in order to integrate offshore wind energy into the system. Submarine cables, offshore substations, and onshore grid connections are typical components of this infrastructure. Electricity from offshore wind turbines is transported by submarine cables to offshore substations, where it undergoes voltage transformation and is then sent by export cables to onshore grid connections. The size and location of the offshore wind farm, the distance to shore, and the grid connection specifications established by regulatory bodies all affect the design and capacity of the grid connection infrastructure [83,84].

Grid Stability and Power Quality Issues

Because offshore wind and other intermittent renewable energy sources fluctuate in power production and wind speed, integrating them into the system can provide problems to power quality and grid stability. The dependability and efficiency of the electrical grid may be impacted by wind generating variability, which can cause frequency variations, voltage fluctuations, and grid instability. Various grid stabilization techniques, including active power management, voltage control, and frequency regulation, are used by grid operators to solve these problems. Furthermore, grid stability and power quality can be less negatively impacted by offshore wind integration with the use of sophisticated grid management and monitoring technology, such as flexible demand response programmes and grid-scale energy storage systems [85,86].

Grid Code Compliance Requirements

Offshore wind farms must adhere to the technical criteria set out by grid code compliance requirements in order to be seamlessly integrated into the electrical grid. These specifications address things like fault ride-through capabilities, reactive power support, voltage and frequency management, and grid connection specifications. Grid code compliance guarantees OWFs function in line with grid operator specifications and add to the grid’s overall stability and dependability. Before offshore wind projects are linked to the grid, compliance testing and certification procedures ensure that they fulfil these standards, reducing the possibility of system disruptions and guaranteeing the safe and effective integration of offshore wind energy into the grid [85-87].

Challenges And Future Prospects in Offshore Wind Energy Harvesting

Deep-Water Deployment Challenges

Deep water turbine deployment is one of the major obstacles to offshore wind energy collection. For technical and financial reasons, deep-water situations are unsuitable for traditional fixed-bottom foundation designs. Deep-water deployment of floating wind turbines appears to have promise, but issues with platform stability, mooring systems, and installation logistics still need to be resolved. Furthermore, deep-water locations could pose environmental and regulatory issues that need to be carefully considered, along with mitigating plans.

Technological Innovation Needs

To overcome current obstacles and realize the full potential of offshore wind energy harvesting, technological innovation must continue. Turbine design and materials, foundation technologies, installation techniques, and grid integration solutions are important areas of innovation. Larger rotor diameters, sophisticated blade materials, and cutting-edge control systems are a few examples of how advances in turbine design may lower total costs and increase energy collection efficiency. Similar to this, developments in foundation technologies, including platforms with tension legs and suction buckets, can allow for more affordable deployment in deeper seas. Moreover, advancements in installation techniques, such self-sufficient installation boats and floating crane systems, have the potential to optimize offshore wind farm building processes and minimize installation expenses. Reducing the levelized cost of energy (LCOE) and improving offshore wind energy’s competitiveness in the global energy market require addressing these technical innovation demands.

Potential Solutions and Research Directions

Research and development activities in offshore wind energy harvesting should concentrate on many important areas in order to solve the obstacles and take advantage of the opportunities that lie ahead. First and foremost, multidisciplinary research is required to provide integrated solutions that concurrently address technological, environmental, and socioeconomic issues. Second, studies into cutting-edge materials, production processes, and creative turbine designs can improve the durability, dependability, and performance of turbines. Thirdly, new developments in foundation technologies, such hybrid structures and floating platforms, can open up new offshore wind resources and allow OWFs to operate in a wider geographic area. Furthermore, studies into energy storage technologies, hybrid energy systems, and grid integration strategies might improve offshore wind energy generations dependability and flexibility, facilitating its integration with current energy infrastructure. In order to overcome present obstacles and reach its full potential as a clean, renewable energy source for the future, the offshore wind energy sector has to invest in these research directions and encourage cooperation between business, academia, and government players.

Conclusion

Offshore wind energy is a viable way to solve the world’s energy problems while lessening the effects of climate change. The significance of offshore wind as a clean and renewable energy source is shown by its exponential rise in installations. Offshore wind technology has come a long way, but there are still a number of obstacles to overcome, such as the limitations of deep-water deployment and the ongoing need for technical innovation. Nonetheless, the offshore wind energy industry is well-positioned for further growth and expansion because to continuous research and development activities concentrated on multidisciplinary solutions, such as new materials, foundation technologies, and grid integration techniques. Offshore wind energy may be a key player in the shift to a sustainable energy future by solving these issues and seizing opportunities.

Declaration of Interests

According to the authors, none of their known financial or personal conflicts may have impacted the research presented in this paper.

References

- MD Esteban, JJ Diez, JS Lopez, V Negro (2011) Why offshore wind energy? Renewable energy 36(2): 444-450.

- XZ Li, ZJ Chen, XC Fan, ZJ Cheng (2018) Hydropower development situation and prospects in china. Renewable and Sustainable Energy Reviews 82: 232-239.

- A Bartle (2002) Hydropower potential and development activities. Energy policy 30(14): 1231-1239.

- M Melikoglu (2018) Current status and future of ocean energy sources: A global Ocean Engineering 148: 563-573.

- M Esteban, D Leary (2012) Current developments and future prospects of offshore wind and ocean Applied Energy 90(1): 128-136.

- A Boretti (2020) State-of-the-art of mw-level capacity oceanic current Nonlinear Engineering 9(1): 361-369.

- AH Slocum (2015) Symbiotic offshore energy harvesting and storage Sustainable Energy Technologies and Assessments 11: 135-141.

- GJ Herbert, S Iniyan, E Sreevalsan, S Rajapandian (2007) A review of wind energy Renewable and sustainable energy Reviews 11(6): 1117-1145.

- AD Sahin (2004) Progress and recent trends in wind Progress in energy and combustion science 30(5): 501-543.

- MR Islam, S Mekhilef, R Saidur (2013) Progress and recent trends of wind energy Renewable and Sustainable Energy Reviews 21: 456-468.

- VN Dinh, E McKeogh (2019) Offshore wind energy: technology opportunities and challenges: Energy and Geotechnics. Proceedings of the 1st Vietnam Symposium on Advances in Offshore Engineering. Springer PP. 3-22.

- N Bento, M Fontes (2019) Emergence of floating offshore wind energy: Technology and Renewable and Sustainable Energy Reviews 99: 66-82.

- J Li, G Wang, Z Li, S Yang, WT Chong, et al. (2020) A review on development of offshore wind energy conversion sys International Journal of Energy Research 44(12): 9283-9297.

- A Jacobsen, M Godvik (2021) Influence of wakes and atmospheric stability on the floater responses of the hywind scotland wind Wind Energy 24(2): 149-161.

- S Whitfield (2020) Offshore wind: The new frontier in powering platforms? Journal of Petroleum technology 72(01): 38-40.

- S Roga, S Bardhan, Y Kumar, SK Dubey (2022) Recent technology and challenges of wind energy generation: A Sustainable Energy Technologies and Assessments 52: 102239.

- A Al-Hinai, Y Charabi, SH Aghay Kaboli (2021) Offshore wind energy resource assessment across the territory of oman: A spatial- temporal data analysis. Sustainability 13(5): 2862.

- C Eisenhut, F Krug, C Schram, B Klockl (2007) Wind-turbine model for system simulations near cut-in wind speed, IEEE Transactions on Energy Conversion 22(2): 414-420.

- X Costoya, M DeCastro, D Carvalho, M Gomez-Gesteira (2020) On the suitability of offshore wind energy resource in the United States of America for the 21st century. Applied Energy 262(3): 114537.

- N Masseran, A Razali, K Ibrahim (2012) An analysis of wind power density derived from several wind speed density functions: The regional assessment on wind power in malaysia. Renewable and Sustainable Energy Reviews 16(8): 6476-6487.

- M Bilgili, H Alphan (2022) Global growth in offshore wind turbine Clean Technologies and Environmental Policy 24(7): 2215-2227.

- A Cranmer, E Baker (2020) The global climate value of offshore wind Environmental Research Letters 15(5): 054003.

- X Sun, D Huang, G Wu (2012) The current state of offshore wind energy technology development. Energy 41(1): 298–312.

- W Zhixin, J Chuanwen, A Qian, W Chengmin (2009) The key technology of offshore wind farm and its new development in china. Renewable and Sustainable energy reviews 13(1): 216-

- H Eftekhari, ASM Al-Obaidi, S Eftekhari (2022) Aerodynamic performance of vertical and horizontal axis wind turbines: A comparison review. Indonesian Journal of Science and Technology 7(1): 65-88.

- M Ahmad, A Shahzad, F Akram, MNM Qadri (2022) Determination of efficient configurations of vertical axis wind turbine using design of experiments. Proceedings of the Institution of Mechanical Engineers. Part A: Journal of Power and Energy 236(9): 1558-1581.

- M Ahmad, I Rehman (2023) investigating aerodynamic performance of vertical axis wind turbines using computational techniques. Journal of Power Generation Technology 1(1): 20-41.

- ED Kumara, N Hettiarachchi, R Jayathilake (2017) Overview of the vertical axis wind turbines. Int. J. Sci. Res. Innov. Technol 4: 56-67.

- X Jin, G Zhao, K Gao, W Ju (2015) Darrieus vertical axis wind turbine: Basic research methods. Renewable and Sustainable Energy Reviews 42: 212-225.

- X Wang, X Zeng, J Li, X Yang, H Wang (2018) A review on recent advancements of substructures for offshore wind turbines. Energy conversion and management 158: 103-119.

- X Wang, X Zeng, X Yang, J Li (2018) Feasibility study of offshore wind turbines with hybrid monopile foundation based on centrifuge modeling. Applied energy 209: 127-139.

- P Plodpradit, VN Dinh, KD Kim (2019) Tripod-supported off- shore wind turbines: modal and coupled analysis and a para- metric study using x-sea and fast. Journal of Marine Science and Engineering 7(6): 181.

- MJ Kaiser, B Snyder (2010) Offshore wind energy installation and decommissioning cost estimation in the us outer continental shelf, US of the Interior, Bureau of Ocean Energy Management. Regulation and Enforcement, Herndon, VA TA&R 648.

- C Perez-Collazo, D Greaves, G Iglesias (2015) A review of combined wave and offshore wind Renewable and sustainable energy reviews 42: 141-153.

- H Yang, Y Zhu, Q Lu, J Zhang (2015) Dynamic reliability-based design optimization of the tripod sub-structure of offshore wind Renewable Energy 78: 16-25.

- J Koh, E Ng (2016) Downwind offshore wind turbines: Opportunities, trends and technical Renewable and Sustainable Energy Reviews 54: 797-808.

- E Lozano-Minguez, AJ Kolios, FP Brennan (2011) Multi-criteria assessment of offshore wind turbine support structures. Renewable Energy 36(11): 2831-2837.

- D Micallef, A Rezaeiha (2011) Floating offshore wind turbine aero- dynamics: Trends and future challenges. Renewable and Sustainable Energy Reviews 152(4): 111696.

- A Otter, J Murphy, V Pakrashi, A Robertson, C Desmond (2022) A review of modelling techniques for floating offshore wind tur- Wind Energy 25(5): 831-857.

- AR Henderson, MH Patel (2003) On the modelling of a floating offshore wind turbine. Wind Energy: An International Journal for Progress and Applications in Wind Power Conversion Technology 6(1): 53-86.

- D Roddier, C Cermelli, A Weinstein (2009) Windfloat: a floating foundation for offshore wind turbines—part i: design basis and qualification in: International conference on offshore mechanics and Arctic engineering 43444: 845-853.

- GR Tomasicchio, FD Alessandro, AM Avossa, L Riefolo, E Musci, et al. (2018) Experimental modelling of the dynamic behaviour of a spar buoy wind Renewable energy 127: 412-432.

- NK Liang, JS Huang, CF Li (2004) A study of spar buoy floating Ocean Engineering 31(1): 43-60.

- K Ha, JB Kim, Y Yu, HS Seo (2021) Structural modeling and failure assessment of spar-type substructure for 5 mw floating offshore wind turbine under extreme conditions in the east sea. Energies 14(20): 6571.

- J Chen, MH Kim (2022) Review of recent offshore wind turbine research and optimization methodologies in their Journal of Marine Science and Engineering 10(1): 28.

- JdAY Lucena (2021) Recent advances and technology trends of wind Recent Advances in Renewable Energy Technologies PP. 177-210.

- H Diaz, CG Soares (2020) Review of the current status, technology and future trends of offshore wind farms. Ocean Engineering 209: 107381.

- S Rodrigues, C Restrepo, E Kontos, RT Pinto, P Bauer (2015) Trends of offshore wind projects. Renewable and sustainable energy reviews 49: 1114-1135.

- M Ahmad, A Shahzad, MNM Qadri (2023) An overview of aerodynamic performance analysis of vertical axis wind turbines. Energy & Environment 34(7): 2815-2857.

- M Ahmad, A Shahzad, SI Shah (2023) Experimental investigation and analysis of proposed hybrid vertical axis wind turbine Energy & Environment.

- OT Filsoof, MH Hansen, A Yde, P Bøttcher, X Zhang (2021) A novel methodology for analyzing modal dynamics of multirotor wind Journal of Sound and Vibration 493: 115810.

- S Kozlov, E Sirotkin, E Solomin (2016) Wind turbine rotor magnetic levitation. 2nd International Conference on Industrial Applications and Manufacturing PP. 1-4.

- S Watson, A Moro, V Reis, C Baniotopoulos, S Barth, et al. (2019) Future emerging technologies in the wind power sector: A European perspective. Renewable and sustainable energy reviews 113: 109270.

- WT Chong, KH Wong, CT Wang, M Gwani, YJ Chu, et al. (2017) Cross-axis-wind-turbine: a complementary design to push the limit of wind turbine Energy Procedia 105: 973-979.

- M Ahmad, A Shahzad, F Akram, F Ahmad, SIA Shah (2022) Design optimization of double darrieus hybrid vertical axis wind Ocean Engineering 254: 111171.

- A Pallotta, D Pietrogiacomi, G Romano (2020) HYBRI–A combined savonius-darrieus wind turbine: Performances and flow Energy 19: 116433.

- M Ahmad, MH Zafar (2023) Enhancing vertical axis wind turbine efficiency through leading edge tubercles: A multifaceted anal Ocean Engineering 288: 116026.

- J Joseph, A Sathyabhama (2022) Leading edge tubercle on wind tur- bine blade to mitigate problems of stall, hysteresis, and laminar separation bubble. Energy Conversion and Management 255: 115337.

- ICM Lositano, LAM Danao (2019) Steady wind performance of a 5 kw three-bladed h-rotor darrieus vertical axis wind turbine (vawt) with cambered tubercle leading edge (tle) blades. Energy 175: 278-291.

- I Galparsoro, I Menchaca, JM Garmendia, A´Borja, AD Maldonado, et al. (2022) Reviewing the ecological impacts of offshore wind farms. npj Ocean Sustainability 1(1): 1-8.

- L Wang, B Wang, W Cen, R Xu, Y Huang, et al. (2023) Ecological impacts of the expansion of off- shore wind farms on trophic level species of marine food Journal of Environmental Sciences 139(3).

- J Lloret, A Turiel, J Sole, E Berdalet, A Sabates, et al. (2022) Unravelling the ecological impacts of large-scale offshore wind farms in the mediterranean Science of the Total Environment 824(8): 153803.

- L Bergstrom, L Kautsky, T Malm, R Rosenberg, M Wahlberg, et al. (2014) Effects of off- shore wind farms on marine wildlife-a generalized impact as Environmental Research Letters 9(3): 034012.

- JM Guinotte, VJ Fabry (2008) Ocean acidification and its potential effects on marine ecosystems. Annals of the New York Academy of Sciences 1134(1): 320-342.

- Q Zhou, S Wang, J Liu, X Hu, Y Liu, et al. (2022) Geological evolution of offshore pollution and its long-term potential impacts on marine ecosystems. Geoscience Frontiers 13(11): 101427.

- SC Doney, M Ruckelshaus, J Emmett Duffy, JP Barry, F Chan, et al. (2012) Climate change impacts on marine Annual review of marine science 4(1): 11-37.

- SC Mangi (2013) The impact of offshore wind farms on marine ecosystems: a review taking an ecosystem services perspective. Proceedings of the IEEE 101(4): 999-1009.

- G Fabi, F Luccarini, M Panfili, C Solustri, A. Spagnolo (2002) Effects of an artificial reef on the surrounding soft-bottom community (central adriatic sea). ICES Journal of Marine Science 59(suppl): S343-S349.

- H Farr, B Ruttenberg, RK Walter, YH Wang, C White (2021) Potential environmental effects of deepwater floating offshore wind energy facilities. Ocean & Coastal Management 207(1):

- A Fox, M Desholm, J Kahlert, TK Christensen, I Krag Petersen (2006) Information needs to support environmental impact assessment of the effects of european marine offshore wind farms on birds. Ibis 148: 129-144.

- M Shadman, MM Amiri, C Silva, SF Estefen, E La Ro-vere, et al. (2021) Environmental impacts of offshore wind installation, operation and maintenance, and decommissioning activities: A case study of brazil. Renewable and Sustainable Energy Reviews 144: 110994.

- JTM Machado, M de Andres (2023) Implications of offshore wind energy developments in coastal and maritime tourism and recreation areas: An analytical Environmental Impact Assessment Review 99: 106999.

- P Hou, J Zhu, K Ma, G Yang, W Hu, et al. (2019) A review of offshore wind farm layout optimization and electrical system design methods. Journal of Modern Power Systems and Clean Energy 7(5): 975-986.

- B Perez, R Minguez, R Guanche (2013) Offshore wind farm lay- out optimization using mathematical programming techniques. Renewable energy 53: 389-399.

- J Feng, WZ Shen (2017) Design optimization of offshore wind farms with multiple types of wind turbines. Applied energy 205: 1283-1297.

- RV Rao, VJ Savsani, RV Rao, VJ Savsani (2012) Advanced Optimization Springer.

- M Ahmad, ZL Hussain, SIA Shah, TA Shams (2021) Estimation of stability parameters for wide body aircraft using computational techniques. Applied Sciences 11(5): 2087.

- AC Pillai, J Chick, L Johanning, M Khorasanchi (2018) Offshore wind farm layout optimization using particle swarm optimization. Journal of Ocean Engineering and Marine Energy 4: 73-88.

- Z Ren, AS Verma, Y Li, JJ Teuwen, Z Jiang (2021) Offshore wind turbine operations and maintenance: A state-of-the-art review. Renewable and Sustainable Energy Reviews 144:

- G Rinaldi, PR Thies, L Johanning (2021) Current status and future trends in the operation and maintenance of offshore wind turbines: A review. Energies 14(9): 2484.

- M Scheu, D Matha, M Hofmann, M Muskulus (2012) Maintenance strategies for large offshore wind farms. Energy Procedia 24: 281-288.

- M Sahnoun, D Baudry, N Mustafee, A Louis, PA Smart, et al. (2019) Modelling and simulation of operation and maintenance strategy for offshore wind farms based on multi-agent Journal of Intelligent Manufacturing 30(8): 2981-2997.

- R Komiyama, Y Fujii (2021) Large-scale integration of offshore wind into the Japanese power grid. Sustainability Science 16: 429-448.

- SW Ali, M Sadiq, Y Terriche, SAR Naqvi, MU Mutarraf, et al. (2021) Offshore wind farm-grid integration: A review on infrastructure, challenges, and grid IEEE Access 9: 102811-102827.

- M Bartels, C Gatzen, M Peek, W Schulz, R Wissen, et al. (2006) Planning of the grid integration of wind energy in ger- many onshore and offshore up to the year International journal of global energy issues 25 (3-4): 257-275.

- X Han, F Zhao, J Ma, X Ye, Y Sun (2021) Support grid integration of offshore wind Journal of Physics: Conference Series 1914: 012014.

- A Fernandez-Guillamon, K Das, NA Cutululis, A´Molina-Garcia (2019) Offshore wind power integration into future power systems: Overview and trends. Journal of Marine Science and Engineering 7(11): 399.

-

Muhammad Ahmad*, Iram Rehman. Wind Over Water: Unraveling The Potential of Offshore Wind Energy. Ad Oceanogr & Marine Biol. 4(2): 2024. AOMB.MS.ID.000583.

-

Offshore wind energy; wind resource; fixed offshore; floating offshore; environmental impact; wind farm; iris publishers; iris publisher’s group

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.