Mini Review Article

Mini Review Article

Improvement of the Parameters of Drilling and Blasting Operations in the Conduct of Underground Mining Operations

Mataev Azamat Kalizhanuly*1, Abay Y2 and Қaripolla A3

1Mataev Azamat Kalizhanuly, Ph.D., Professor of the Faculty of Engineering, Kazakhstan

2Қaripolla A, Undergraduate student of KTU named after A. Saginov, Kazakhstan

3Abay Y, Master’s student of KTU named after A. Saginov, Kazakhstan

Mataev Azamat Kalizhanuly, Mataev Azamat Kalizhanuly, Ph.D., Professor of the Faculty of Engineering, Kazakhstan.

Received Date: May 25, 2023; Published Date: June 7, 2023

Object of study

The objects of study are the underground mine of the Atasu deposit.

Goal of research

Conducting research to improve the parameters of drilling and blasting operations in the conduct of underground mining operations.

Problem Statement

In the work, it is necessary to conduct field observations of compliance with the parameters of the BVR during mine workings, analysis of the quality indicators of the explosion and schemes of cutting holes.

It is necessary to conduct research to determine the influence of structural features and strength properties of the rock mass on the parameters of the BVR by numerical analysis of the geomechanically state of the rocks of the contour part.

Background

To date, one of the fundamental problems of mining is the destruction of the mountain range. The efficiency of rock destruction determines the efficiency of the entire mining industry and further the capabilities of the entire industry using the results of the work of mining enterprises. When carrying out horizontal workings, drilling and blasting operations are subject to increased requirements in terms of ensuring the necessary collapse of the rock after the explosion and its high-quality crushing, high stability of the workings and their delineation in accordance with the project, as well as economic indicators. First of all, reducing the cost of BVR.

It is possible to ensure the fulfillment of the specified requirements through the development of methods for calculating the optimal parameters of drilling and blasting operations, ensuring the optimal specified separation and quality of crushing of the rock mass during penetration. Existing technologies for drilling and blasting operations do not always provide the required crushing of rock, which leads either to a high yield of oversized or to regrinding of rock. There may be several reasons for these phenomena: incorrect selection of the type of explosive for a given rock mass, overestimated or underestimated consumption of explosives, an error in the selection of parameters for the mesh of the location of boreholes, etc. The disadvantage of this technique is that the coefficients used in the calculations have a very wide range of changes in the accepted values, which depend more often on the level of training and intuition of the specialist performing the calculations, rather than on the actual mining and geological conditions. As a result, the parameters of the BVR are set according to the average values, which adversely affects the efficiency of blasting operations. A slightly different approach is proposed in the method of [2] which is based on determining the radius of the cracking zone around the exploding explosive charge [3] notes that during an explosion in the explosive charge array two active zones are formed around its location, the dimensions of which affect the efficiency of the BVR.

Analysis of cut-in borehole schemes

An analysis of the effectiveness of drilling and blasting operations in capital and preparatory workings, especially when they are carried out on rocks of increased strength and strength, shows that good enough results are not always achieved. As a rule, an underestimated value of the borehole utilization factor (KISH), unsatisfactory delineation of workings, low penetration rates and labor productivity of tunnelers are obtained.

In order to solve negative factors, along with other measures, for many years attempts have been made to improve the passports of drilling and blasting operations (BVR), their optimization. A lot of work has been carried out in this direction by various researchers and production workers. Various recommendations were made that made it possible to increase the efficiency of blasting operations in specific mining and geological conditions. The main part of the recommendations is devoted to improving the parameters of cutting boreholes, since the indicator of their effective explosion predetermines the efficiency of the explosion of the entire set of borehole charges of explosives.

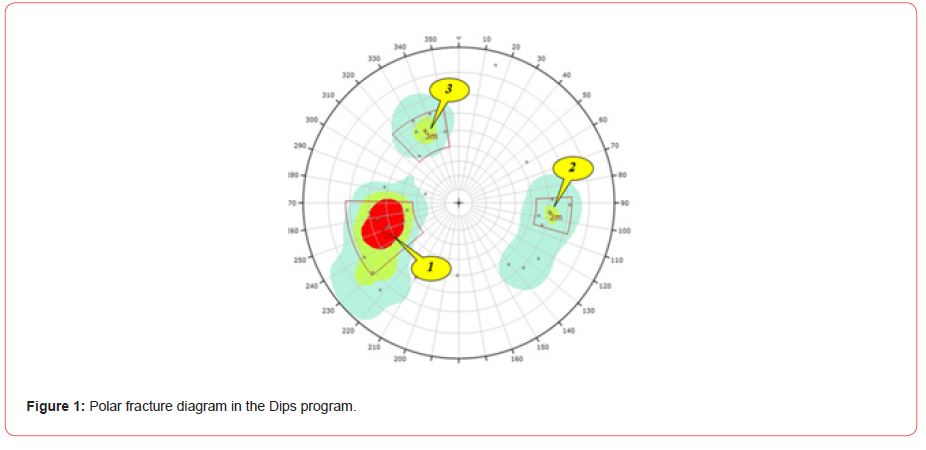

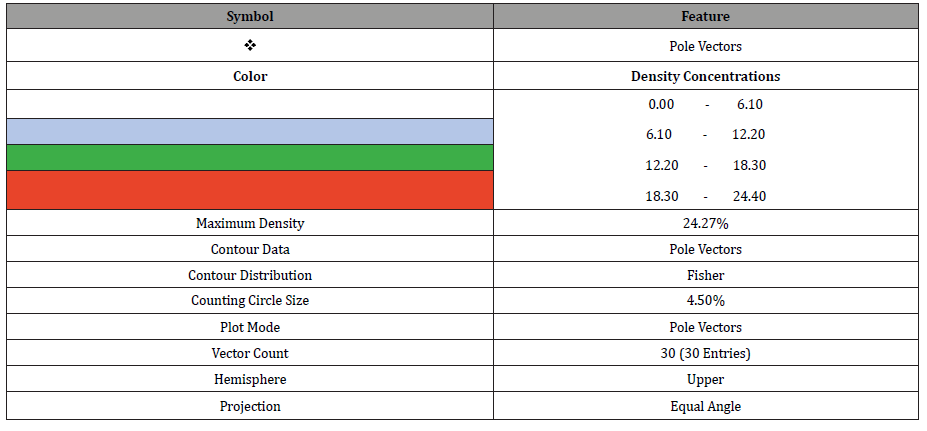

Based on the results of the survey of cracks in the workings of the horizon +44.0 m (block No. 1 scraper ort No. 4, loading No. 2 scraper ort No. 2, horizon +60.0 block No. 8 chamber No. 3), a polar fracture diagram was constructed [Figure 1], according to which 3 crack systems were identified, the elements of occurrence of which are shown [Table 1].

Table 1: Elements of occurrence.

Studies and analysis of more than 100 BVR passports used in various mining enterprises of the world have established [8] that when carrying out mine workings on rocks with a strength coefficient on the scale of prof. M.M. Protodyakonov f = 10-12 or more, preference is given to straight cuts. The use of wedge cuts is not always effective. For example, the experience of blasting operations using a vertical wedge cut in such conditions has shown that it provides a KISH value not exceeding 0.7. So, with a depth of boreholes of 2.5 m, such a cut provides a movement of the face by 1.7-1.9 m per cycle, and at a depth of boreholes up to 3.7 only by 2.2-2.5 m. Due to this, the obtained technical and economic indicators are not high enough - the yield of the rock mass from 1m is approximately 1.08-1.20 m3, and the specific consumption of explosives is 1.1-1.4 kg / m3.

Directly in the underground workings of the mine, the structural properties of the massif and the linear survey of cracks are determined, which in turn are the main indicators for determining the geological strength index (GSI).

Acknowledgement

None.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sverdlovsk (1987) The project "Adjustment of the project for the reconstruction of the West Karazhal mine".

- Hoek E (2017) Practical Rock Engineering.

- Hoek E, Carter TG, Diederichs MS (2013) Quantification of the Geological Strength Index chart. ARMA 8(3).

- Hoek E, Brown ET (1997) Practical Estimates of Rock Mass Strength. Int Jr Rock Mech and Min Sci Pergamon 34(8): 1165-1186.

- Bieniawski ZT (1989) Engineering Rock Mass Classifications. John Wiley, Pp 251.

-

Mataev Azamat Kalizhanuly*, Abay Y and Қaripolla A. Improvement of the Parameters of Drilling and Blasting Operations in the Conduct of Underground Mining Operations. Adv in Mining & Mineral Eng. 1(2): 2023. AMME.MS.ID.000506.

-

Simulation game, Serious game, Active learning, Interactive simulation, Problem based learning, Mineral exploration, Decision making skills

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.