Mini Review

Mini Review

Pyrometallurgical Recycling of Spent Li-Ion Batteries – Concept and Trends

V Niščáková, A Gubóová and AS Fedorková*

Department of Physical Chemistry, Faculty of Sciences, Pavol Jozef Šafárik University in Košice, Slovak Republic, Slovakia

AS Fedorková, Department of Physical Chemistry, Faculty of Sciences, Pavol Jozef Šafárik University in Košice, Moyzesova 11, 04154, Košice, Slovak Republic, Slovakia

Received Date:February 06, 2024; Published Date:February 15, 2024

Abstract

As the global demand for lithium batteries continues to surge, driven by the rapid proliferation of electric vehicles, renewable energy storage systems, and portable electronic devices, the responsible management of end-of-life batteries becomes imperative. This review underscores the significance of recycling lithium batteries and is aimed specifically at one technological approach-pyrometallurgy.

Keywords:Lithium-ion batteries; recycling; pyrometallurgy; circular economy; waste management

Introduction

Lithium-ion batteries (LIBs) have become ubiquitous in our modern world, since their discovery in 1991by Sony Inc., furthermore powering everything from smartphones to electric vehicles. The market is experiencing a swift rise in demand for LIBs, the unpredictable upswing in raw material prices presents an inevitable hurdle for future large-scale production. According to reports, lithium prices have almost tripled over the past decade. Future manufacturing may encounter challenges also due to a global scarcity of essential elements (Li, Co, and Ni) [1-4]. While these batteries offer impressive energy density, low self-discharge rate, light weight and efficiency, their widespread use raises concerns about environmental impact and resource depletion [5,6]. In this mini review, we explore the importance of recycling lithium batteries to mitigate issues and promote a sustainable future. Hydrometallurgy and pyrometallurgy are two main approaches used to recycle spent LIBs. We introduce one of the mentioned approaches of recycling spent lithium batteries, concretely pyrometallurgy process, in more detail.

The Importance of Recycling of Spent Lithium-Ion Batteries

The generation of 1 kWh of electricity demands 0.26 kWh of fossil energy and leads to greenhouse gas emissions of 74 g, exclusively attributed to the battery’s production. The aggregate average greenhouse gas emissions linked to producing 1 Wh of storage capacity are determined to be 110 g of CO2 [7]. Also, the process of extracting Li, Ni, Co, and Al from raw materials demands a substantial energy input and results in the emission of significant greenhouse gases. Further, supplies of raw materials for the production of LIBs are being depleted at a rapid rate. Roughly half of the globally produced cobalt is predominantly employed in LIBs. Moreover, cobalt plays a crucial role not only in batteries, but in others range of applications for its unique catalytic properties. Another significant component is metal lithium. Still, it remains a finite resource and its supplies are running out fast. There has been a more than twofold increase in lithium usage (65 % in battery production). [8] Lithium is generally obtained from hard rock spodumene minerals and lithium salts are retrieved from seawater and liquid brine reservoirs. Most of these are situated in China and/or South America. The separation and further processing methods and very diverse and revolve around source materials [9].

To generate 1 ton of lithium through traditional means of primary production, either 250 tons of spodumene or 750 tons of mineral-rich brine need to be extracted. This process significantly depletes ground water resources, requiring 1 ton of lithium to be extracted with 1,900 tons of water [10]. LIB recycling contributes positively to energy conservation and environmental protection by mitigating these impacts. Recycling batteries has the capacity to slash greenhouse gas emissions by 81%–98% and completely eliminate SOx emissions in the manufacturing of cathode materials [11]. Recycling is important process that allows recovery of end-of-life products, and it has become accepted practice in energy manufacturing, where some of more developed industries are able to have up to 60% recycling rates [12]. Recycling of LIBs is more desirable than straight disposal of end-of-life batteries. Not only due to involvement of toxic and hazardous elements that can pollute the environment, but also because of tapering off the supply of lithium and other crucial metals which is growing ever more limited [12].

Minimization of extraction of raw materials is another significant reason for effective and efficient recycling process. The scarcity of critical metals along with far reaching mining processes affecting the climate and habitats rank among the most pressing environmental issues. In theory, metals can be considered endlessly recyclable as their physical properties are permanent. However, the reality is more complex. The structure of LIB also plays crucial role in its recyclability and is deemed as quite difficult because of cell design as well as rather complicated cell chemistry [13].

Pyrometallurgy

Pyrometallurgy is a promising method for recycling lithium batteries, offering an efficient and environmentally sustainable approach to recover valuable materials. This process involves the use of high temperatures to extract and separate metals from battery components. It allows for the recovery of valuable metals like lithium, cobalt, nickel, and other elements present in the battery.

These metals can be reused in the production of new batteries [14]. In a standard pyrometallurgical process, organic materials undergo high-temperature combustion, followed by the reduction and smelting of metal/oxides, and ultimately, the refinement and separation of cobalt post-leaching [15].

The pyrometallurgical approach to recycle valuable metals involves oxidizing or melting the targeted metals, whereas is easily and quickness. Resulting of this quickly process is an alloy (transition metals) and a slag [16]. One of the main advantages of pyrometallurgical technology is its suitability for large-scale industrial application [17]. Also, as mentioned before, it is highly adaptable for variety of raw materials [18] (Li, Co, Ni and more) and last but not least, it is acid and alkali free. Pyrometallurgical process also does not produce much waste, however it does have quite high energy consumption and is rather expensive [14].

Notwithstanding these merits, the pyrometallurgical methodology employed for the recycling of utilized lithium batteries is perpetually undergoing refinement, adaptation, and frequently integration or supplementation with alternative recycling modalities, notably the hydrometallurgical recycling methodology. Windisch- Kern et al. [19] introduced the InduRed reactor concept, which holds promise as a novel approach for the efficient recovery of lithium. In the course of the InduMelt experiments utilizing lithium nickel cobalt aluminum oxide (NCA) and lithium nickel manganese cobalt oxide (NMC) cathode materials, the removal of initial lithium from the reactor exceeded 90% and 75%, respectively. The absence of lithium accumulation in either the slag or the metal phase underscores the significant potential of this technology in paving the way for innovative approaches to lithium recovery from the waste of lithium-ion batteries [19]. Holzer et al. [20] investigated two distinct reactor configurations within a novel pyrometallurgical recycling process aimed at recovering lithium and phosphorus. The study involved the utilization of two distinct crucible types, resulting in divergent lithium yields. Furthermore, the fundamental efficacy of the proposed concept in treating LFP (lithium iron phosphate) was explored, revealing a phosphorus removal rate of 64% concomitant with a lithium removal rate of 68% [20].

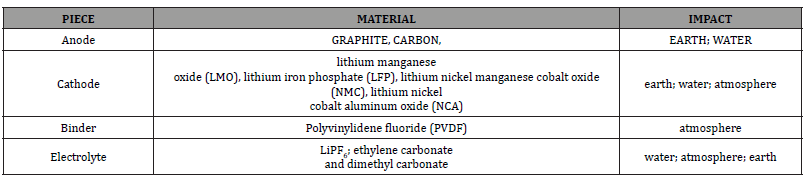

Table 1:Environmental impact of battery components.

Conclusion

LIBs are ever more desirable in our way of more ecological approach to energy, thus the need for proper disposal and with it closely related recyclability is growing. Limited amounts of raw materials used in LIBs are pushing towards advancements in recycling processes to make them more accessible and economical. Many leading producing companies are investing in new and/or improved approaches, which is showing the necessity of properly tuned, finely working recycling process [21]. More in depth analysis and extensive research is needed to provide comprehensive understanding of various processes in battery recycling and their individual challenges that need to be properly addressed in order to achieve its full potential.

Acknowledgement

This work was supported by the Slovak Research and Development Agency under contracts APVV-20-0138, APVV-20- 0111 and by the project Regeneration of used batteries from electric vehicles, ITMS2014+: 313012BUN5, which is part of the Important Project of Common European Interest (IPCEI).

References

- X Shen, Bo Li, Xin Hu, Chuan Fu Sun, Yong Sheng Hu, et al. (2021) Recycling Cathodes from Spent Lithium-Ion Batteries Based on the Selective Extraction of Lithium. ACS Sustain. Chem Eng 9(30): 10196-10204.

- R Morina, D Callegari, D Merli, G Alberti, P Mustarelli, et al. (2022) Cathode Active Material Recycling from Spent Lithium Batteries: A Green (Circular) Approach Based on Deep Eutectic Solvents. ChemSusChem, 15(2): e202102080-e202102085.

- S Natarajan, V Aravindan (2018) Recycling Strategies for Spent Li-Ion Battery Mixed Cathodes. ACS Energy Lett 3(9): 2101-2103.

- Y Guo, F Li, H Zhu, G Li, J Huang, et al. (2016) Leaching lithium from the anode electrode materials of spent lithium-ion batteries by hydrochloric acid (HCl). Waste Manag 51(1): 227-233.

- S Sambamurthy, S Raghuvanshi, KS Sangwan (2021) Environmental impact of recycling spent lithium-ion batteries. Procedia CIRP 98(2): 631-636.

- H Zheng, Jiaqi Huang, Tao Dong, Yifan Sha, Haitao Zhang, et al. (2022) A novel strategy of lithium recycling from spent lithium-ion batteries using imidazolium ionic liquid. Chinese J Chem Eng 41(1): 246-251.

- JF Peters, M Baumann, B Zimmermann, J Braun, M Weil (2017) The environmental impact of Li-Ion batteries and the role of key parameters – A review. Renew Sustain Energy Rev 67(2): 491–506.

- H Bae, Y Kim (2021 Technologies of lithium recycling from waste lithium ion batteries: A review. Mater Adv 2(5): 3234-3250.

- M Kaya (2022) State-of-the-art lithium-ion battery recycling technologies. Circ Econ 1(2): 1-5.

- G Harper, Roberto Sommerville, Emma Kendrick, Laura Driscoll, Peter Slater, et al. (2019) Recycling lithium-ion batteries from electric vehicles. Nature 575(7781): 75-86.

- T Or, SWD Gourley, K Kaliyappan, A Yu, Z Chen (2020) Recycling of mixed cathode lithium-ion batteries for electric vehicles: Current status and future outlook. Carbon Energy 2(1): 6-43.

- L Gregoir, K Van Acker (2022) Metals for Clean Energy: Pathways to solving Europe’s raw materials challenge pp. 1-117.

- DL Thompson, Jennifer M Hartley, Simon Lambert, Muez Shiref, Gavin DJ Harper, et al. (2020) The importance of design in lithium ion battery recycling-a critical review. Green Chem 22(22): 7585-7603.

- M Zhou, B Li, J Li, Z Xu (2021) Pyrometallurgical Technology in the Recycling of a Spent Lithium Ion Battery: Evolution and the Challenge. ACS ES T Eng 1(10): 1369-1382.

- X Zheng, Wenfang Gao, Xihua Zhang, Mingming He, Xiao Lin, et al. (2017) Spent lithium-ion battery recycling – Reductive ammonia leaching of metals from cathode scrap by sodium sulphite. Waste Manag 60(1): 680-688.

- B Watson, B Carlson, A Smirnova (2024) Innovative methodology for advanced battery recycling research demonstrated with electrochemical extraction. J Power Sources 594(1): 234025-234029.

- C Liu, J Lin, H Cao, Y Zhang, Z Sun (2019) Recycling of spent lithium-ion batteries in view of lithium recovery: A critical review. J Clean Prod 228(1): 801-813.

- TP Hendrickson, O Kavvada, N Shah, R Sathre, CD Scown (2015) Life-cycle implications and supply chain logistics of electric vehicle battery recycling in California. Environ Res Lett 10(1): 1-5.

- S Windisch Kern, A Holzer, C Ponak, T Hochsteiner, H Raupenstrauch (2021) Thermal analysis of lithium ion battery cathode materials for the development of a novel pyrometallurgical recycling approach. Carbon Resour Convers 4(2): 184-189.

- A Holzer, S Windisch Kern, C Ponak, H Raupenstrauch (2021) A novel pyrometallurgical recycling process for lithium-ion batteries and its application to the recycling of LCO and LFP. Metals 11(1): 1–22.

- AM Abdalla, Mas F Abdullah, Mohamed K Dawood, Bo Wei, Y Subramanian, et al. (2023) Innovative lithium-ion battery recycling : Sustainable process for recovery of critical materials from lithium-ion batteries,” J. Energy Storage, vol. 67, no. April, p. 107551

-

V Niščáková, A Gubóová and AS Fedorková*. Pyrometallurgical Recycling of Spent Li-Ion Batteries – Concept and Trends. Adv in Mining & Mineral Eng. 1(2): 2024. AMME.MS.ID.000509.

-

Lithium-ion batteries; recycling; pyrometallurgy; circular economy; waste management

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.