Research Article

Research Article

Friction Stir Welding Using a Vertical Milling Machine: A Cost-Effective Technique for Joining Metals

AR Anil Chandra1*, V Bharathi1 and TS Srivatsan2

1Department of Mechanical Engineering, B.M.S. College of Engineering, Bangalore, India

2Department of Mechanical Engineering, The University of Akron, Akron, Ohio, USA

AR Anil Chandra, Department of Mechanical Engineering, B.M.S. College of Engineering Bangalore 560 019, India

Received Date:March 14, 2024; Published Date:March 26, 2024

Abstract

Friction stir welding (FSW) is a time-tested process for the joining of both similar metals and dis-similar metals that are both essential and desirable for use in various industries where high weld strength coupled with minimum heat affected zone (HAZ) is preferred. Such weldments usually tend to have less defects, a better retention of mechanical properties, negligible distortion coupled with less residual stress when compared with fusion welding. However, the welding machines from original equipment manufacturers (OEMs) are often expensive and cannot easily be reconfigured to the requirements of an end-user. Re-configuring conventional milling machine for friction stir welding was shown to be an effective ingenious approach in published literature and is chosen in the present study. Aluminium alloy, the equivalent of AlSi7Mg or A356, is widely chosen for use in engine casing applications is the material chosen for this study. This alloy is known for its remarkable resistance to corrosion coupled with high strength. The ‘proof-of-concept’ study revealed an excellent weldment in terms of improved tensile strength and minimum defects in the weldment. This study does encourage in the development of a cost-effective friction stir welding set-up to revolutionize the ageing machine shop in industries.

Keywords:Aluminum alloy (LM25); Friction Stir Welding; Tensile strength; Elongation

Introduction

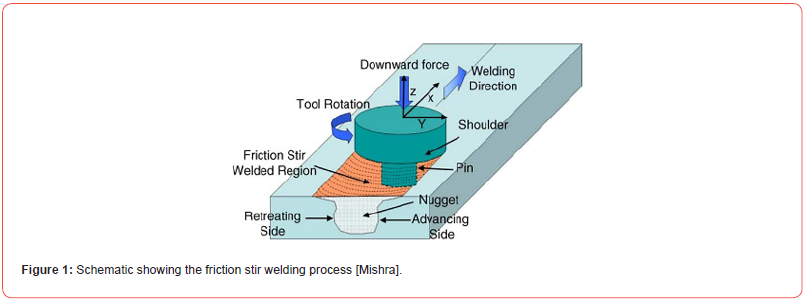

Friction stir welding (FSW), is a solid-state welding process, that is often used for the joining of work pieces at a temperature well below their melting temperature. This welding technique does permit the joining of materials, which cannot be easily welded using the conventional welding techniques. This welding technique was invented in 1991 at The Welding Institute (TWI) [Cambridge, United Kingdom]. This welding technique does enable in the joining of non-weldable aluminium alloys belonging to the 5XXX series [1]. Apart from aluminium alloys, this welding technique has been used to join magnesium alloys as well as alloys of lead and alloys of zinc. An investigation on FSW of the magnesium alloy AZ61A [9.5mm thick] was carried out with much success at The Welding Institute [TWI]. Joining of a magnesium alloy with an aluminium alloy was made possible using this technique [2]. A schematic of the friction stir welding technique or process is show in Figure 1. The technique or process makes use of a non-consumable rotating tool, which is made to traverse in a well-defined path along the joint so as to eventually produce the weldment. The welding tool consists of a board shoulder and a pin having a certain profile. General observations have revealed that if butt joints are to be made, the pin length should be same as thickness of the chosen work pieces. While the pin traverses along the line of joint, the shoulder remains in contact with the top surface of the work piece, thereby enabling in avoiding expelling of the plasticized material. Aspects specific to clamping arrangements, tool related knowledge, and optimized welding process variable have been developed over time. The welding tools are made from a wear resistant material, which does possess excellent properties at high temperatures. Various process parameters to include the following:

a. Tool rotational speed

b. Feed rate

c. Tool shoulder diameter

d. Pin angle, and

e. Axial force, have been found to affect the quality of the

weld, and thereby exert an influence on mechanical properties

of the weld joint. The welding process variables does produce a

considerable effect on the amount of heat that is generated and

the resultant strength of the weld joint. Due to inappropriate flow

of the plasticized metal, microstructural analysis did reveal the

existence of ‘tunnel’-type defects [1]. The effect of welding process

parameters on mechanical properties of friction stirs welded

aluminium plates did reveal improved hardness. The best hardness

was essentially obtained at high rotational speed and medium

traverse speed of the various tool profiles [3-5]. An analysis of

variance (ANOVA) study revealed that percentage contribution

of the axial force on tensile strength of the joint was highest. This

was followed by traverse speed and then tool rotation speed [6].

Researchers have successfully used friction stir welding technique

to fabricate metal matrix composites [7,8].

The heat affected zone (HAZ) and thermo-mechanically affected zone (TMAZ) were found to be minimum for friction stir welding (FSW) when compared to conventional welding techniques. The average hardness of the TMAZ was found to be slightly lower than that of weld nugget [7-9]. The aluminium alloy, A356 or LM 25, widely studied and well documented in published literature on friction stir welding showed good weldability in combination with improved tensile strength, hardness, compressive strength and impact strength. Over the years, researchers have fabricated a LM25/ZrO2 composite. In this aluminium alloy metal-matrix composite the zirconia particles are added to improve weldability while concurrently being beneficial to achieving high weldment strength [9]. The chosen aluminium alloy (LM 25), i.e., the AlSi7Mg or A356, is chosen for use in engine casing applications and is a difficult material to join using the existing fusion welding techniques. Pressure welding is arguably the best alternative while processing using the friction stir welding technique did yield best strength properties [10]. The present study focusses on friction stir welding of the chosen aluminium alloy, i.e., LM-25, using a reconfigured milling machine. Reconfiguring a milling machine for the purpose friction stir welding has been attempted before [11]. The present study is an extension of the previous experiment.

Material and Methods

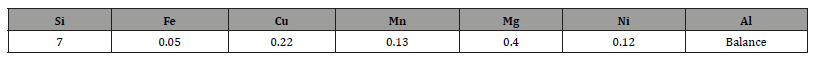

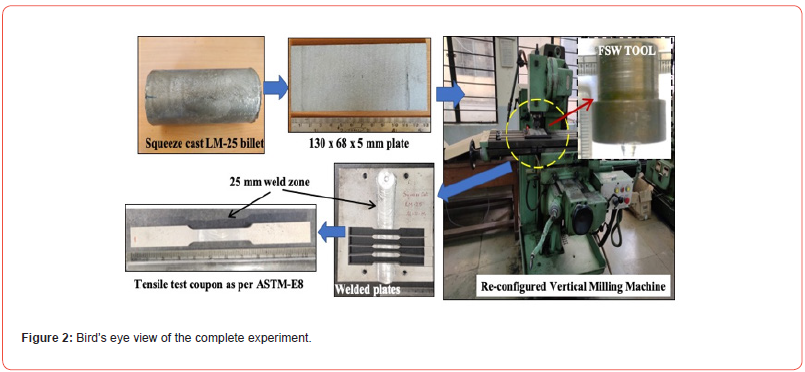

The nominal chemical composition of the chosen aluminium alloy (LM-25) used in the present study is provided in Table 1. The cast billet was cut into 5 mm thick plates using electric discharge machining (EDM) and the plates were butt welded in a reconfigured milling machine using an appropriate friction stir weld tool. The spindle of the milling machine was fit with a collet so as to accommodate the tool used for friction stir welding. This is shown in Figure 2.

Table 1:Nominal chemical composition of aluminum alloy LM-25 [in weight percent].

Results and Discussion

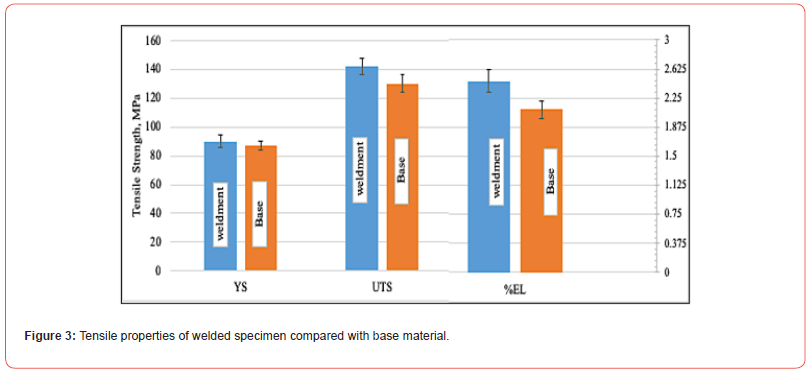

The initial trials were carried out to optimize the process parameters in order to obtain a 25 mm wide sound weld. Trial runs were followed by the actual experimentation process. Tensile test specimens were precision cut from the as-welded plates (as shown in Figure 2) and in accordance with ASTM E-8 Standard. No major surface defects were noticed. The welding appeared impressive to the naked eyes and the optimized weld parameters used are a tool rotation speed of 2000 rpm, a feed rate of 6 mm/ min for a tool shoulder having a diameter of 25-mm. The room temperature tensile tests were carried out at a strain rate of 1 mm/ minute and the test results are shown in Figure 2. For the purpose of comparison, a cast billet was tested for tensile strength using a similar procedure. Three specimens were tested in order to ensure repeatability. The yield strength (YS), ultimate tensile strength (UTS) and percent elongation (%) to failure [εf] were determined.

It is evident from Figure 3 that overall quality of the weld is good since the tensile properties have not deteriorated much when compared to the base material. In fact, marginal improvement in ductility, quantified by percent elongation, is an indication of microstructural grain refinement coupled with minimal porosity as is reported in the published literature. The present study does present ample opportunity to re-configure a vertical milling machine to perform the task of friction stir welding. Furthermore, the process was made repeatable by recording the axial load using a dynamometer. Also, attaching sensors to measure both the speed and feed rate does make the process more reliable.

Conclusion

Friction stir welding (FSW) is a time-tested process for the joining of both similar metals and dissimilar metals. In this independent research study, an attempt was made to reconfigure an aged vertical milling machine to carry out or perform the friction stir welding (FSW) process. In the present study an attempt was made to join two 5-mm thick plates of the cast aluminium alloy (LM- 25). The weldment did reveal acceptable to good tensile properties thereby providing an indication of the feasibility of using a vertical milling machine for performing the friction stir welding process and with the possibility of integrating the machine with sensors more meaningful and repeatable results was possible.

Acknowledgement

The authors wish to thank the Management, Principal and the Head, Department of Mechanical Engineering, of BMS College of Engineering (Bangalore, India) for providing both the permission and facilities for carrying out this research study along with providing the desired and required financial support.

References

- Salih Omar S, Hengan Ou, W Sun, DG McCartney (2015) A review of friction stir welding of aluminium matrix composites. Materials & Design 86(1): 61-71.

- RS Mishra, ZY Ma (2005) Friction stir welding and processing. Materials Science and Engineering: R: Reports 50(1–2): 1-78.

- Serio Livia, Davide Palumbo, Luigi Alberto Ciro De Filippis, Umberto Galietti, Antonio Domenico Ludovico (2016) Effect of friction stir process parameters on the mechanical and thermal behavior of 5754-H111 aluminum plates. Materials 9(3): 122-125.

- Hassan Adel Mahmood, Mohammed Almomani, Tarek Qasim, Ahmed Ghaithan (2012) Effect of processing parameters on friction stir welded aluminum matrix composites wear behavior. Materials and Manufacturing Processes 27(12): 1419-1423.

- Subramanya Prabhu, Murthy Amar, Shettigar Arun, Herbert Mervin, Rao Shrikantha (2018) Friction stir welding of Aluminium matrix composites–A Review. MATEC Web of Conferences 144(2): 03002-03005.

- Devanathan C, A Suresh Babu (2014) Friction stir welding of metal matrix composite using coated tool. Procedia Materials Science 6(1): 1470-1475.

- Sachin kumar P, S Narendranath, D Chakradhar (2018) Study on microstructure and tensile properties of fly ash AMCs welded by FSW. AIP Conference Proceedings 1943(1): 1-10.

- Govindan Karthikeyan, Jinu Gowthami Thankachi Raghuvaran, Vijayalakshmi Pandian (2017) Weldability Study of LM25/ZrO2 Composites by Using Friction Welding. Materia (Rio de Janeiro) 22(3): e11855-e11860.

- Mroczka K, A Pietras, P Kurtyka (2012) Microstructure and properties of 6082 aluminium alloy frictions stir welded with different parameters of welding. Zvaranie/Svarovani 61(1-2): 7-12.

- Al Zahrani MA, Alsoruji G, Moustafa EB, Mosleh AO, Mohamed SS (2023) Optimization of Friction Stir Processing Parameters for Improvement of Mechanical Properties of AlSi7Mg0.2 Alloy. Coatings 13(10): 1667-1670.

- Bharathi V, B R Ramji, Prabhu Swamy N R, Anil Chandra A R (2022) Statistical Analysis of Friction-Stir Welding of Al- 6063 Alloys, Journal of Mines, Metals and Fuels: Volume 70(8A): 1-479.

-

AR Anil Chandra*, V Bharathi and TS Srivatsan. Friction Stir Welding Using a Vertical Milling Machine: A Cost-Effective Technique for Joining Metals. Adv in Mining & Mineral Eng. 1(3): 2024. AMME.MS.ID.000511.

-

Aluminum alloy (LM25); Friction Stir Welding; Tensile strength; Elongation

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.