Research Article

Research Article

Application of (Bio)Chemical Engineering Concepts and Tools to Model GRC-s, and Some Essential CCM Pathways in Living Cells. Part 3. Applications in the Bioengineering Area

Gheorghe Maria1,2*

1Department of Chemical and Biochemical Engineering, Politehnica University of Bucharest, Polizu Str. 1-7, Bucharest 011061, Romania

2Romanian Academy, Chemical Sciences section, Calea Victoriei 125, Bucharest 010071, Romania

Gheorghe Maria, Dept. of Chemical and Biochemical Engineering, Politehnica University of Bucharest, Romanian Academy, Chemical Sciences section, Calea Victoriei 125, Bucharest 010071, Romania

Received Date: December 22, 2023; Published Date: May 01, 2024

Abstract

In the 1-st part of this work the general chemical and biochemical engineering (CBE) concepts and rules are briefly reviewed, together with the rules of the control theory of nonlinear systems (NSCT), all in the context of deriving deterministic modular structured cell kinetic models (MSDKM) and of hybrid structured modular dynamic (kinetic) models (HSMDM) (with continuous variables, based on cellular metabolic reaction mechanisms). In such HSMDM, the cell-scale model (including nano-level state variables) is linked to the biological reactor macro-scale state variables for improving the both model prediction quality and its validity range. By contrast, the current (classical/default) approach in biochemical engineering and bioengineering practice for solving design, optimization and control problems based on the math models of industrial biological reactors is to use unstructured Monod (for cell culture reactor) or Michaelis-Menten (if only enzymatic reactions are retained) global kinetic models by ignoring detailed representations of metabolic cellular processes.

The applied engineering rules to develop MSDKM and HSMDM dynamic math models presented in the 1-st and 2-nd parts of this paper are

similar to those used in the CBE, and in the NSCT. As exemplified in the 3&4 parts of this work, the MSDKM models can adequately represent the

dynamics of cell-scale CCM (central carbon metabolism) key-modules, and of Genetic Regulatory Circuits (GRC) / networks (GRN) that regulate

the CCM-syntheses. As reviewed in the 2-nd part of this paper, an accurate and realistic math modelling of individual GERM-s (gene expression

regulatory module) kinetic models, but also various genetic regulatory circuits (GRC) / networks (GRN). (e.g. toggle-switch, amplitude filters,

modified operons, etc.) can be done by only using the novel holistic ’whole-cell of variable-volume’ (WCVV) modelling framework introduced and

promoted by the author. Also, special attention was paid in the 2-nd part to the conceptual and numerical rules used to construct various individual

GERM-s kinetic models, but also various GRC-s / GRN-s modular kinetic models from linking individual GERM-s of desired regulatory properties,

quantitatively expressed by their performance indices (P.I.-s). As exemplified in the Parts 3 and 4 of this work, the use of MSDKM and of HSMDM

models (developed under the novel WCVV modelling framework) to simulate the dynamics of the bioreactor and, implicitly, the dynamics of the

cellular metabolic processes occurring in the bioreactor biomass, presents multiple advantages, such as:

a) A higher degree of accuracy and of the prediction detailing for the bioreactor dynamic parameters (at a macro- and nano-scale level) and,

b) The prediction of the biomass metabolism adaptation over tens of cell cycles to the variation of the operating conditions in the bioreactor;

c) Prediction of the CCM key-species dynamics, by also including the metabolites of interest for the industrial biosynthesis.;

d) Prediction of the CCM stationary reaction rates (i.e. Metabolic fluxes) allow to in-silico design gmo of desired characteristics.

As proved by Maria [1-5], and Yang, et al. [176], the modular structured kinetic models can reproduce the dynamics of complex metabolic syntheses

inside living cells. This is why, the modular GRC dynamic models, of an adequate mathematical representation, seem to be the most comprehensive

mean for a rational design of the regulatory GRC with desired behaviour [178]. Once experimentally validated, such extended structured cellular

kinetic models MSDKM including nano-scale state variables are further linked to those of the bioreactor dynamic models (including macro-scale

state variables), thus resulting HSMDM models that can satisfactorily simulate, on a deterministic basis, the self-regulation of cell metabolism

and its rapid adaptation over dozens of cell cycles to the changing bioreactor reaction environment, by means of complex GRC-s, which include

chains of individual GERM-s. In a HSMDM, the cell-scale model (including nano-level state variables) is linked to the biological reactor macro-scale

state variables for improving the both model prediction quality and its validity range. Due to such particulars, as exemplify here, the immediate

applications of such MSDKM and HSMDM kinetic models are related to solving various difficult bioengineering problems, such as:

a) In-silico off-line optimize the operating policy of various types of bioreactors, and

b) In-silico design/check some gmo-s of industrial use able to improve the performances of several bioprocess/bioreactors.

Note:

a) Part 1 (General concepts) of this paper will soon appear in Current Trends in Biomedical Eng & Biosci., (Juniper publ, Irvine CA, USA)

b) Part 2 (Mathematical modelling framework) of this paper will soon appear in Annals of Reviews & Research, (Juniper publ, Irvine CA, USA)

In the absence of these papers (parts 1& 2), the reader is asked to consult the references [4,5]. “c) Part 4. (Applications in the design of some genetically modified micro-organisms (GMOs)) of this paper will soon appear in Annals of Systems Biology (Peertechz publ, USA)”

Keywords:Biochemical engineering concepts applied in bioinformatics; Deterministic modular structured cell kinetic model (MSDKM); Hybrid structured modular dynamic (kinetic) models (HSMDM); Whole cell variable cell volume (WCVV) modelling framework; Whole cell constant cell volume (WCCV) modelling framework; Individual gene expression regulatory module (GERM); Genetic regulatory circuits (GRC), or networks (GRN); Chemical and biochemical engineering principles (CBE); Rules of the control theory of nonlinear systems (NSCT); Kinetic model of glycolysis in E. coli; Glycolytic oscillations; GRC of mercury-operon expression regulation in modified E. coli cells; Three-phase fluidized bioreactor (TPFB) for mercury uptake by cloned E. coli cells; Fed-batch bioreactor (FBR) for tryptophan (TRP) production using in-silico design E. coli GMO cells; Tryptophan production maximization in a FBR; Design GRC of a genetic switch (GS) type, with the role of a biosensor in GMO E. coli cells; Pareto optimal front to maximize both biomass and succinate production by using design GMO E. coli cells based on the in-silico tested gene knockout strategies; Optimal operating policies of a fed-batch bioreactor (FBR) used for monoclonal antibodies (mAbs) production maximization; Mercuryoperon expression regulation in modified E. coli cells; Cloned E. coli cells with mercury-plasmids; Gene knockout strategies to design optimized GMO E. coli for succinate production maximization; Pareto optimal front to maximize both biomass and succinate production in batch bioreactors (BR) using GMO E. coli cells

Introduction

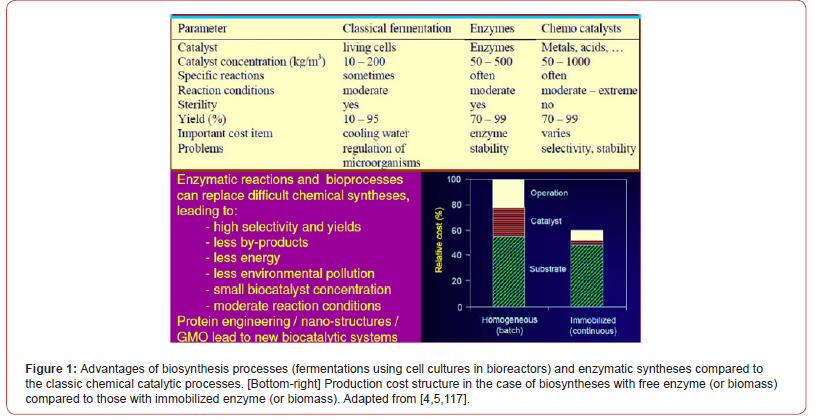

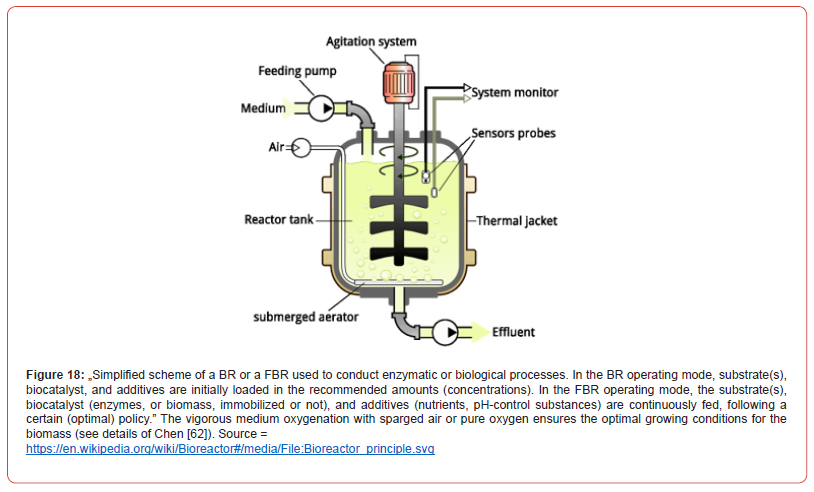

In the last decades, there has been a tendency to replace the complex processes of fine chemical synthesis, highly energy-consuming and generating large amounts of toxic waste, with biosynthesis processes (using isolated and purified enzymes, or cell cultures as bio-catalysts). The motivation is given by the multiple advantages offered by enzymatic processes (Figure 1):

a) Very high selectivity;

b) Very high conversion;

c) Does not generate toxic by-products;

d) Very mild reaction conditions, easy to achieve without high

costs (low temperatures of 20-60°c, normal pressure, PH within

controllable limits).

Thus, in recent years, a significant number of enzymatic or biological

industrial processes have been reported [4-9] in order to

obtain chemical products/derivatives in the fine organic synthesis

industry, in the pharmaceutical industry, in the food industry or in

the detergent industry, by using various bioreactors with cell or enzyme

cultures [6,9]. Among these new processes are the production

of derivatives of monosaccharides, organic acids, alcohols, amino

acids, etc., using mono- or multi-enzymatic reactors, or bioreactors

with cell cultures used in the production of yeast, food additives,

recombinant proteins (enzymes, vaccines), biopolymers [6,7,10].

The development of a sustainable biological process must consider

several aspects related to the characteristics of the biocatalyst, the

integration of the process and the minimization of costs, satisfying

economic, environmental / safety and social objectives [11-13].

When the scale-up of a new biological process is aimed at, in a first

stage the characteristics of the biological process are determined

on an experimental basis (process kinetic model, optimal reaction

conditions, biomass deactivation kinetics). Next, several biochemical

engineering problems must be solved, consisting of:

a) Choosing the type of biological reactor (with cell cultures)

most suitable for the studied bioprocess (with perfect mixing

CSTR, or with total displacement if the biomass is immobilized

in a fixed layer, [7]);

b) Choosing the optimal mode of operation of the selected bioreactor

(discontinuous BR; semi-continuous (fed-batch) FBR

with a variable feeding of flow-rate, substrates/enzymes; discontinuous

with intermittent addition of biomass/substrate

BRP; or continuous stirred tank reactor CSTR, with a continuous

feeding and evacuation of the liquid-phase, mixed types,

etc. [7]);

c) Choosing how to use the biocatalyst (biomass in a free state

or immobilized on a suitable solid/gel support). Biomass immobilization

is desirable because it leads to an increase in its

stability and duration of activity, with favourable economic

effects, since the cost of the non-immobilized biocatalyst contributes

the most to the production cost, as can be seen from

(Figure 1) [14]. More details on the biocatalyst immobilization

can be found in the literature [15-17].

The importance of optimal operation of biological reactors. In the case of the biological reactors (with free, or immobilized biomass), the trend in the biosynthesis industry is to use complex systems, with more efficient genetically modified micro-organisms (GMO), and employing sophisticated but efficient immobilization systems, which prevent the premature inactivation of the biomass due to mechanical and chemical stress from the bioreactor environment. Thus, modern biological processes, together with the multi-enzymatic ones, prove to be very effective in the biosynthesis of numerous chemical compounds, thus competing in terms of efficiency with organic chemical synthesis, proceeding with high selectivity and specificity, by reducing consumption of energy and generating less environmental pollution (Figure 1). This characteristic of industrial biosynthesis is exploited for various economic purposes (industry, medicine, environment, agriculture, fuel production) [18,19].

However, industrial bioprocesses still have a limited spread due to the high costs of enzyme/biomass isolation and stabilization on a suitable support, as well as its high sensitivity in relation to the operating conditions, the rather low reproducibility of the biological process due to biomass changes from one cell cycle to another, and of the difficult controllability of the bioreactor. However, many of these drawbacks can be overcome by an efficient immobilization of the biomass on suitable supports, by using suitable GMO-s with superior catalytic activity, and/or by optimizing the working conditions and the operation mode for the selected biological reactor, by using an advanced off-line in-silico analysis of the engineering part of bioprocess development based on effective MSDKM and HSMDM kinetic math models and effective numerical algorithms.

As proved in the literature [1,2,4,5,20-23] , and shortly reviewed in the Part-1 of this work [4], the in-silico (math/kinetic model-based) numerical analysis of biochemical or biological processes are proved to be not only an essential but also an extremely beneficial tool for engineering evaluations aiming to determine the optimal operating policies of complex multi-enzymatic reactors [10,24-29], or bioreactors [4,5,7,20,30,31]. In the Part-1 of this work, the general chemical and biochemical engineering (CBE) concepts and rules are briefly reviewed, together with the rules of the control theory of nonlinear systems (NSCT), all in the context of deriving deterministic modular structured cell kinetic models (MSDKM) and of hybrid structured modular dynamic (kinetic) models (HSMDM) (with continuous variables, based on cellular metabolic reaction mechanisms) [4].

In the Part-2 of this work [4], a special attention is paid to the authors’ contributions related to dynamics simulation of the gene expression regulatory modules (GERM) and of genetic regulation circuits/networks (GRC/GRN) in living cells, by introducing and promoting the novel concepts of a novel cell modelling framework, that is the so-called “Whole cell variable cell volume” (WCVV) dynamic models. The advantages of using the WCVV models to simulate the cell metabolic processes has been proved when building-up dynamic models of modular structures that can reproduce complex metabolic CCM-based syntheses and GRC-s inside living cells. These advantages of the more realistic WCVV approach are briefly underlined and exemplified when developing kinetic representations of the gene expression regulatory modules (GERM) that control the protein synthesis and homeostasis of metabolic processes. Exemplifications are made in the Part-2 comparatively to classical (default, incorrect) “Whole cell constant cell volume” (WCCV) dynamic models, and in the Parts 3&4 of the work when design GMO-s and optimize bioreactor operation using effective MSDKM and HSMDM kinetic math models and effective numerical algorithms [4].

The topics approached in this paper belongs to the emergent field of Systems Biology, defined as “the science of discovering, modelling, understanding and ultimately engineering at the molecular level the dynamic relationships between the biological molecules that define living organisms” (Leroy Hood, Inst. Systems Biology, Seattle). Systems Biology is one of the modern tools, which uses advanced mathematical simulation models for in-silico re-design of GMO-s that possess specific and desired functions and characteristics. In fact, as discussed in the Part-1 of this work, this emergent research/applicative field is closely inter-connected with the socalled ’Computational systems biology’, or simply ’Bioinformatics’. as depicted in the (Figure 9) of Part-1 of this work [4,19]. In fact, all these relatively novel research/applicative fields are strongly related, and inspired from the CBE, NSCT principles and rules (see Figures 4-6, 8 of Part-1 of this work [4], and GERM/GRC modelling of Part-2[4]). These rules involve application of the classical CBE modelling techniques (mass balance, thermodynamic principles), algorithmic rules, and NSCT concepts and rules (Sections 2.3.5, and 2.3.6 of Part-2 [4]). The metabolic pathway representation with continuous and/or stochastic variables remains the most adequate and preferred representation of the cell processes, the adaptable- size and structure of the lumped model depending on available information and the utilisation scope.

The translation of the CBE and NSCT concepts/rules in Systems

Biology, Computational biology, and Bioinformatics is leading to obtain

extended structured cellular kinetic models MSDKM including

nano-scale state variables adequately representing the dynamics of

the key-reaction-modules of the cell CCM and GRN. If the MSDKM

model is further linked to those of the bioreactor dynamic model

(including macro-scale state variables), the result is the HSMDM

dynamic model that can satisfactorily simulate, on a deterministic

basis, the self-regulation of the cell central metabolism and its rapid

adaptation over dozens of cell cycles to the changing bioreactor

reaction environment, by means of complex GRC-s, which include

chains of individual GERM-s. In a HSMDM, the cell-scale model (including

nano-level state variables) is linked to the biological reactor

macro-scale state variables for improving the both model prediction

quality and its validity range. Due to such particulars, as exemplify

here, the immediate applications of such MSDKM and HSMDM

kinetic models are related to solving various difficult bioengineering

problems, such as:

a) In-silico off-line optimize the operating policy of various types

of bioreactors, and

b) In-silico design/check some GMO-s of industrial use able to

improve the performances of several bioprocess/bioreactors.

As exemplified in the 3&4 parts [4], the use of MSDKM and

of HSMDM models (developed under the novel WCVV modelling

framework) is able to simulate the dynamics of the bioreactor simultaneously

with the dynamics of the cellular metabolic processes

occurring in the bioreactor biomass. Such extended HSMDM

models present multiple advantages, such as:

a) A higher degree of accuracy and of the prediction detailing

for the bioreactor dynamic parameters (at a macro- and nano-

scale level);

b) The prediction of the biomass metabolism adaptation over

tens of cell cycles to the variation of the operating conditions

in the bioreactor;

c) Prediction of the CCM key-species dynamics, by also including

the metabolites of interest for the industrial biosynthesis.;

d) Prediction of the ccm stationary reaction rates (i.e. Metabolic

fluxes) allows to in-silico design GMO of desired characteristics.

This work is aiming to prove, by using a certain number of case

studies, solved and published by the author, the feasibility and advantage

of using the relatively novel HSMDM concept by coupling

extended CCM-, and GRC-based cell structured deterministic nano-

scale models with the macro-scale state-variables of the analyzed

bioreactor models. The resulted hybrid dynamic model was

successfully used for engineering evaluations. To exemplify the theoretical

concepts described in the Parts 1-2 of this work [4], and

the above mentioned advantages of HSMDM models, several case

studies of industrial interest, previously solved by the author, are

briefly reviewed in the Parts 3&4 of this work [4]. More case studies

have been presented in detail by [4,5,20,32]. Among them, it is to

mention the followings:

a) In-silico design of a genetic switch in E. coli with the role of a

biosensor [4,5,33-36];

b) An HSMDM math model able to simulate the dynamics of the

mercury-operon expression in E. coli cells, and its self-regulation

over dozens of cell cycles, simultaneously with the dynamics

of the macro-level state variables of a semi-continuous reactor

(SCR) of a three-phase fluidized bioreactor type (TPFB).

The same extended model was used to In-silico design of

cloned E. coli cells (with variable mer-plasmid concentrations)

aiming at maximize the biomass capacity of mercury uptake

from wastewaters [37-40].

c) An HSMDM math model able to simulate the dynamics of

key-species of the CCM of E. coli cell coupled with the simulation

of the macro-scale state variables of a batch reactor (BR).

The HSMDM model was used to in-silico design of a GMO E.

coli with a maximized capacity of both biomass and succinate

(SUCC) production. The used numerical techniques were those

of the gene knock-out, and of the Pareto-front for multi-objective

problems [41].

d) The use of an HSMDM math model to in-silico design of a GMO

E. coli with a modified glycolytic oscillator [42-59]. Complex

MSDKM structured models including CCM and GRC modules

are able to predict conditions for oscillations occurrence for

various cell processes [43,44,46-50,52,176]. As studied by

Yang et al. [176], “all biochemical reactions in organisms cannot

occur simultaneously due to constraints of thermodynamic

feasibility and resource availability, just as all trains in a country

cannot run simultaneously. Therefore, oscillations provide

overall planning and coordination for the inner workings of

the cellular system. This seems to be contrary to the theoreti

cal basis of GEMs (genome-scale metabolic models), which are

based on the steady-state hypothesis and flux balance analysis

[177], but just as computers will not operate in the same

way as the human brain, this difference can be understood and

accepted, so that non-equilibrium theory and the steady-state

hypothesis have been and will continue to coexist and guide

our reasoning [176].”

e) The use of an extended HSMDM math model to simulate the

dynamics of the nano-scale CCM key-species, and of the tryptophan

(TRP)-operon expression, and its self-regulation, together

with the dynamics of the macro-scale state-variables of a FBR

including genetically modified E. coli cultures. Eventually, this

dynamic model was used to design/check a GMO E. coli, and to

determine the multi-control optimal operating policy of a bioreactor

(FBR) to maximize the tryptophan (TRP) production

[4,5,30,44,45,60-66].

f) An MSDKM math model able to simulate the dynamics of

key-species of the CCM of E. coli cell involved in the synthesis of

Phenyl-alanine (PHA). The HSMDM model was used to in-silico

re-configure the metabolic pathway for Phenyl-alanine synthesis

in E. coli [32] to maximize its production. That implies to

modify the structure and activity of the involved enzymes, and

modification of the existing regulatory loops. Searching variables

of the formulated mixed-integer nonlinear programming

(MINLP) multi-objective optimization problem are the followings:

the regulatory loops (that is integer variables, taking “0”

value when the loop has to be deleted, or the value “1” when it

has to be retained); the enzyme expression levels (that is continuous

variables), and all these in the presence of the stoichiometric

and thermodynamic constraints. To solve this complex

optimization problem, two contrary objectives are formulated:

maximization of the PHA selectivity, with minimization of cell

metabolites’ concentration deviations from their homeostatic

levels (to avoid an unbalanced cell growth). The elegant solution

of the problem is the so-called Pareto-optimal front, which

is the locus of the best trade-off between the two adverse objectives.

By choosing two problem solution alternatives from

this Pareto-curve [32,4,5], it is to observe the large differences

between the two pathways into the cell, fully achievable by

using the genetic engineering techniques to produce desirable

GMO-s.

g) A HSMDM model to simulate the dynamics of the key-species

and of the FBR state-variables used for monoclonal antibodies

(mAbs) production. This extended dynamic model was used for

the in-silico off-line derivation of the multi-objective optimal

control policies to maximize the mAbs production in an industrial

FBR [7].

Some of these case studies are discussed in the Parts 3 and 4 of this work [4]. For the others, the reader is asked to consult the above indicated references.

MCase study no. 1. In-Silico Modulate Operating Conditions Leading to Glycolytic Oscillations and Their Interference with the TRP Synthesis in E. coli Cells

Abbreviations and notations used in this section 2

Cellular oscillations – an overview

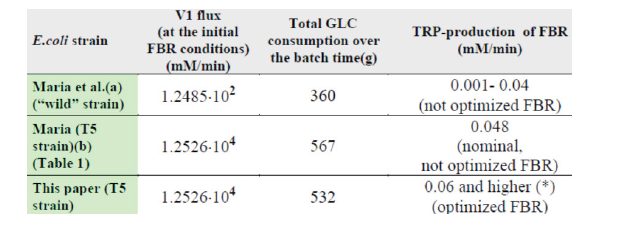

This section is aiming at presenting a lumped structured MSDKM dynamic math model used to simulate wild or GMO E. coli having the glycolytic oscillations as key-node to induce oscillations in the whole CCM. As an example, the influence of glycolytic oscillations on the synthesis of excretable tryptophan (TRP) is discussed as a direct application of industrial interest. The same MSDKM math model can be used to in-silico design of a GMO E. coli with a modified glycolytic oscillator of practical interest [42-59]. As presented in this case study, and in the next case study, the here elaborated HSMDM model can be further used “for in-silico design of a GMO E. coli with a modified glycolytic oscillator [42,44-46,68]. The HSMDM model can be further used as the core of a modular dynamic model used to simulate the CCM and regulation of various metabolite systheses, with application to in silico reprogramming of the cell metabolism to design GMO of various applications [4,20]. One example is the In-silico off-line optimization of the operating conditions of a fed-batch bioreactor (FBR) with design GMO E. coli to maximize the production of tryptophan (TRP) [30,60]. Thus, compared to a simple batch bioreactor (BR) using a wild E. coli cell culture, the TRP production was increased with 73% (50% due to the novel GMO E. coli strain, and 23% due to the model-based optimization of the variable feeding of the FBR). [30,44-46,60,66,68].

Generally, autonomous oscillations of species levels in the glycolysis express the self-control of this essential cellular pathway belonging to the cell CCM, and this phenomenon takes place in a large number of bacteria. Oscillations of glycolytic intermediates in living cells occur according to the environmental conditions, and to the cell characteristics, especially the Adenosin-triphosphate (ATP)-recovery system. Determining the conditions that lead to the occurrence and maintenance of the glycolytic oscillations can present immediate practical applications. Such a model-based analysis allows in silico (model-based) design of genetic modified micro-organisms (GMO) with certain characteristics of interest for the biosynthesis industry, medicine, etc. Based on our kinetic model validated in previous works, this paper is aiming to in silico identify operating parameters and cell factors leading to the occurrence of stable glycolytic oscillations in the E. coli cells. As long as most of the glycolytic intermediates are involved in various cellular metabolic pathways belonging to the CCM, evaluation of the dynamics and average level of its intermediates is of high importance for further applicative analyses. As an example, by using a lumped kinetic model for tryptophan (TRP) synthesis from literature, this section highlights the influence of glycolytic oscillations on the oscillatory TRP synthesis through the PEP (phosphoenolpyruvate) glycolytic node. The analysis allows further TRP production maximization in a Fed-batch bioreactor (FBR).

Cellular oscillations – an overview

Autonomous oscillations of species levels in the glycolysis express the self-control of this essential cellular pathway belonging to the CCM, and this phenomenon takes place in a large number of bacteria. “The study of glycolytic oscillations might, therefore, prove crucial for the general understanding of the cell metabolism regulation and the connections among different components of the metabolism. The key question in this context is the mechanism of the oscillations but, despite much work over the last 40 years, it remains unsettled” [69,70].

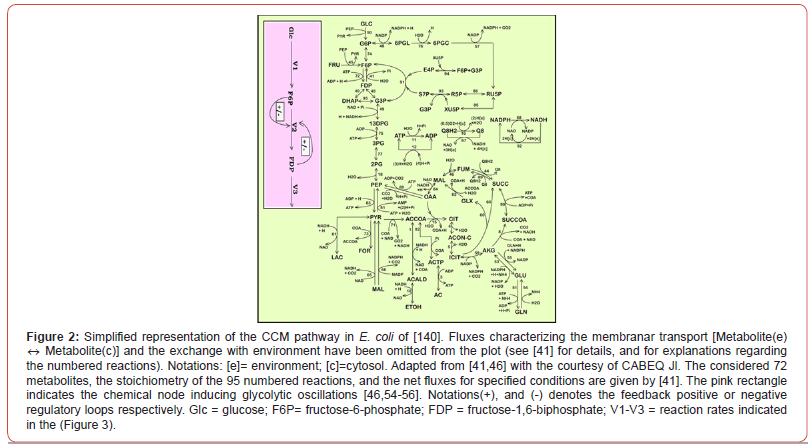

A model able to simulate the dynamics of the cell CCM must include

linked modules relating to

a) The glycolysis (Figures 2 &3);

b) The phosphotransferase (PTS)-system for GLC import into the

cell (Figure 2);

c) The pentose-phosphate pathway (PPP) to generate NADPH

and pentoses (5-carbonsugars), as well as ribose 5-phosphate

(R5P, a precursor for the synthesis of nucleotides);

d) The tricarboxylic acid cycle (TCA);

e) The ATP-recovery system, and several other pathways [4,71-

74].

Modelling bacteria CCM, or parts of CCM, is a subject of very high interest, because the CCM is the essential part of any systematic and structured (model-based) in-silico analysis of the cell metabolism with immediate applications, such as: biosynthesis optimization, metabolic fluxes evaluation [75], model-based design of GMO with target characteristics of various applications in the industry, medicine, etc. [4,5,18,19,32,37-39,44-46,68,76-78]. To cope with the very high complexity of cell metabolic processes, involving ca. 104 species concentrations, 103 gene expression transcription factors, and ca. 105 enzymatic reactions, adaptable reduced dynamic models, of ‘building-blocks’ like modular construction, have been developed over the last decades (see the reviews of [1,2,4,5]), with including individual/lumped species and/or reactions. Modelling the glycolysis dynamics is of particular interest, because most of its intermediates are starting points for the internal production of various metabolites of industrial/medical use (e.g. amino-acids, succinate, citrate, etc; [4,5,30,60,71,72]).

By using two adequate dynamic models validated by the author

in previous studies (Tables 2&3), this paper exemplifies how the

model-based analysis can be used

a) to predict some of the internal/environmental conditions inducing

glycolytic oscillations in the E. coli culture grown in a

fed-batch bioreactor (FBR), and

b) to simulate the influence of the glycolytic oscillations on the

TRP oscillatory synthesis by means of the common key-species

PEP. Industrial applications are immediate seeking for TRP

production optimization. The glycolytic oscillations occurrence

will be analysed vs. external ([GLC] in the bulk-phase),

and internal factors (that is the ATP recovery rate, dependent

on the cell phenotype) [42,44,46,79].

The tested FBR

The in-silico study of the glycolytic oscillations, connected to the TRP synthesis dynamics, is performed by considering a FBR with a suspended E. coli cell culture, operated with the initial/nominal conditions given in (Table 1). It is worth mentioning that the bioreactor includes an excess of sparged air, and necessary nutrients for a balanced growth of the cell culture. This FBR was used by Chassagnole et al. [67] to develop experimental kinetic studies to validate their CCM model (denoted here by CHASSM). The same experiments have also been used by Maria [42] to validate his reduced kinetic model of glycolysis (denoted here by MGM). The adopted SBR (Table 2-A, with a constant dillution “D”), or FBR model (Table 2B, with a time step-wise variable feeding policy, over j = 1,…, Ndiv equal time-arcs, and for Ndiv =5 ) is a classical one [80], developed with the following main hypotheses [43,45,46,68]:

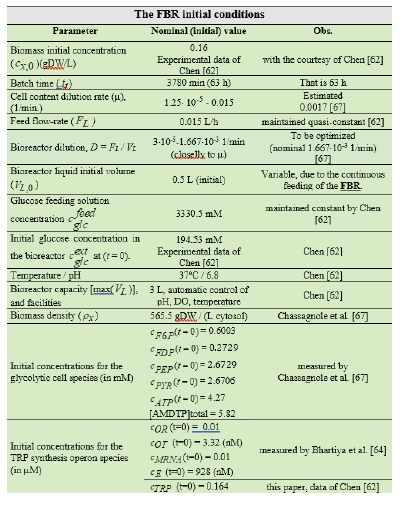

Table 1: The nominal initial operating conditions of the FBR used by Chen [62] to collect the kinetic data of the TRP synthesis by using a suspended culture of a wild, or of a genetically modified E. coli cells (T5 strain). This semi-continuous bioreactor (SBR/FBR) with suspended E. coli cell culture used to simulate the glycolytic and TRP synthesis processes [44,60], and to optimize the FBR operating policy [30].

a) The operation is isothermal, iso-ph, and iso-DO (dissolved oxygen);

b) Nutrients are added to the FBR, in recommended quantities,

together with an aeration in excess (with air, or pure oxygen)

for ensuring an optimal biomass maintenance;

c) A perfectly mixed liquid phase (with no concentration gradients).

The mass balance equations account for the main species in the FBR -bulk and of the cellular ones referring to the glycolysis and TRP synthesis dynamics. To obtain the species time-trajectories with a satisfactory accuracy, a low-order stiff integrator (“ODE23S”) of the Matlab™ software was used.

Dynamic models for the oscillating glycolysis coupled with the TRP oscillating synthesis in the E. coli cells ”Glycolysis model

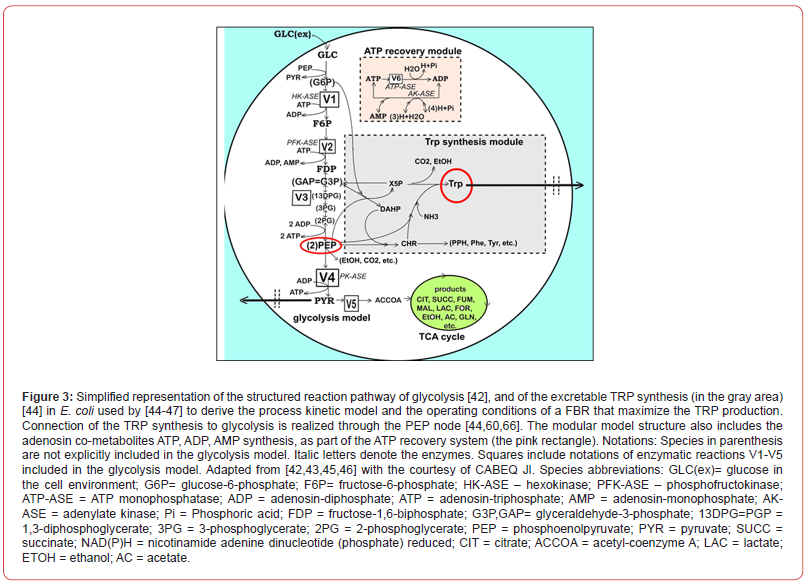

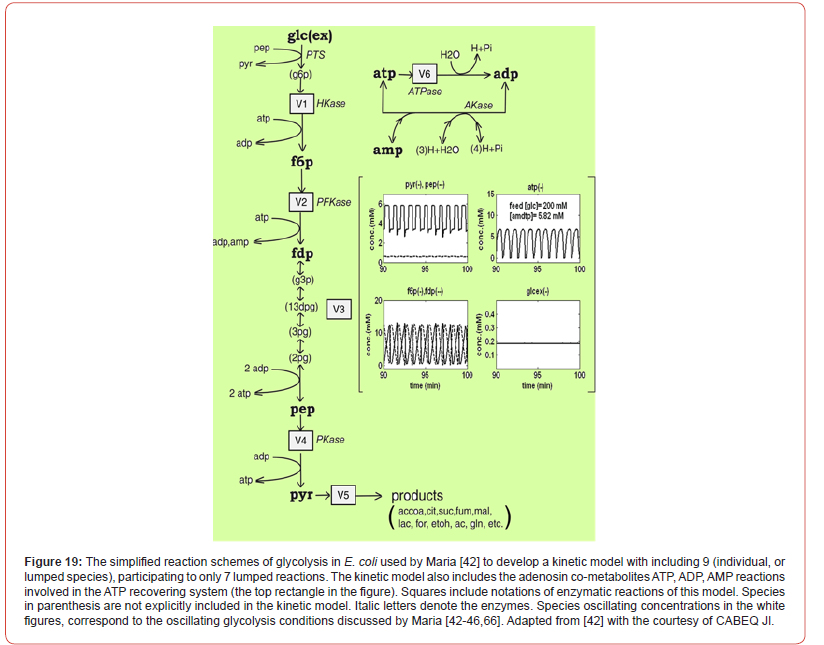

Glycolysis is a sequence of enzymatic reactions (Figures 2-3) that converts glucose (GLC) into pyruvate (PYR). “The free energy released by the subsequent TCA originating from PYR is used to form the high-energy molecules ATP, and NADH that support the glycolysis and the other enzymatic reactions into the cell” [79]. Consequently, an adequate modelling/simulation of the glycolysis kinetics is of high importance because its intermediates are entry/ exit points to/from glycolysis. “For instance, most of the monosaccharides, such as fructose or galactose, can be converted to one of the glycolytic intermediates. In turn, glycolytic intermediates are directly used in subsequent metabolic pathways. For example, DHAP (an intermediate in the F6P conversion to G3P in Figure 2) is a source of the glycerol that combines with fatty acids to form fat. In addition, NADPH is also formed by the PPP, which converts GLC into R5P, which is used in the synthesis of nucleotides and nucleic acids.” PEP is, as well, the starting point for the synthesis of essential Aminoacids (AA) such as TRP, cysteine, arginine, serine, etc. [44,81]. Due to the huge importance of the glycolysis in simulating the CCM dynamics, intense efforts have been invested both in the experimental study, and in modeling of its dynamics in various bacteria [82-85].

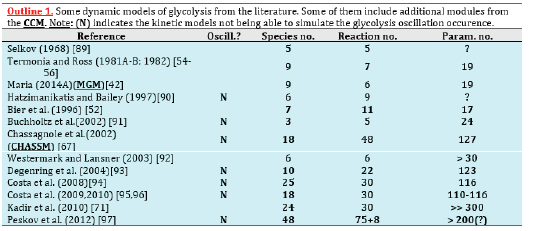

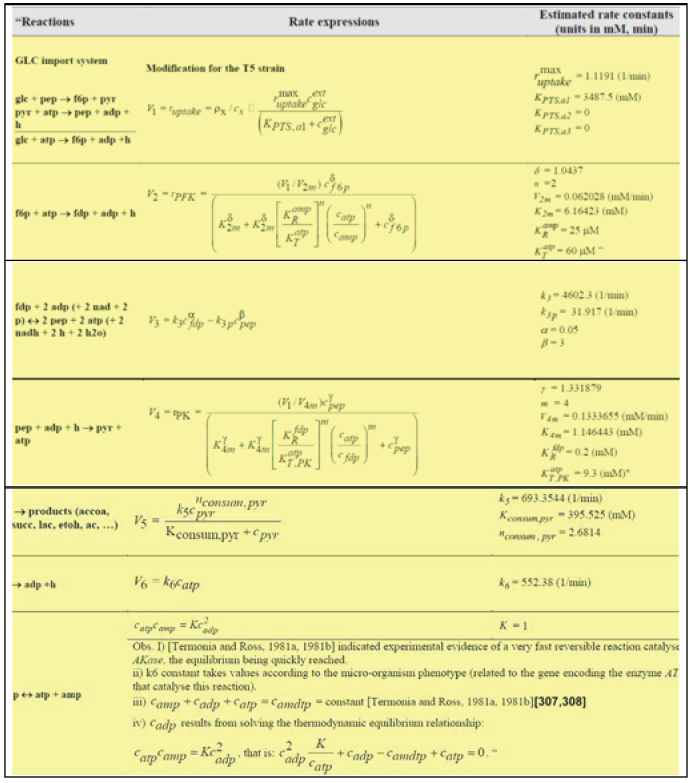

However, modelling in detail the glycolysis kinetics and its regulation is a difficult task due to its high complexity. Despite these dilemmas, a large number of extended/lumped kinetic models have been proposed in the literature (review of Maria [42]), some of them being mentioned in (Outline 1), of a complexity varying in the range of 18-30 key species, 48-52 key reactions, with a total of 24-300 or more rate constants. Most of these models are however too complex to be easy to use and to estimate the rate constants. Besides, their adequacy is not always satisfactory. Thus, with few exceptions, most of the mentioned models cannot satisfactorily simulate the glycolytic oscillations on a deterministic basis. Starting from the reaction pathway of (Figure 2), from the CHASSM and other kinetic models (Outline 1; [41]), and by applying certain lumping algorithms [86-88], a reduced kinetic model of glycolysis (MGM) has been proposed by Maria [42]. MGM is accounting for 9 key species, 7 lumped reactions, and includes 17 rate constants (Table 2-A). Its parameters have been identified “by using the experimental kinetic data of [67,76].” The MGM model proved that it can satisfactorily simulate the dynamics of the glycolytic species concentrations (steady state QSS, oscillatory, or transient) according to various internal/external regimes, related to:

Table 2-A:Species mass balance in the SBR model, with a constant dillution “D”, describing the dynamics of the cellular glycolysis species according to the MGM kinetic model of Maria [42]. The glycolysis kinetic model also includes the modification of Maria et al. [44,60] when coupling with the TRP synthesis model. The model parameters are given by Maria [42,44,60]. Notations are given in the Figure 2 caption.

Table 2-B:Species mass balance in the SBR model, with a constant dillution “D”, describing the dynamics of the cellular glycolysis species according to the MGM kinetic model of Maria [42]. The glycolysis kinetic model also includes the modification of Maria et al. [44,60] when coupling with the TRP synthesis model. The model parameters are given by Maria [42,44,60]. Notations are given in the Figure 2 caption.

a) The GLC concentration level/dynamics in the bioreactor

b) The cell total energy resources in A(MDT)P, and

c) The cell phenotype responsible for activity of the enzymes involved

in the ATP utilization/recovery system.

The MGM has been inserted in the SBR (Table 2-A, with a constant dillution “D”), or in the FBR bioreactor model template (Table 2B. with a time step-wise variable feeding policy, over j = 1,…, Ndiv equal time-arcs, and for Ndiv =5 ) when simulating the dynamics of the [GLC] in the liquid-phase simultaneously with that of the cell metabolites. A direct connection between the macro-scale (bioreactor bulk-phase) and the nano-scale (cellular) process variables is thus realized. According to Franck [59], “oscillations in chemical systems represent periodic transitions in time of species concentrations”. Thus, “spontaneous occurrence of self-sustained oscillations in chemical systems is due the coupled actions of at least two simultaneous processes. Oscillations sourced in a so-called oscillation node (that is a chemical species, or a reaction), on which concomitant rapid positive (perturbing) and slow negative (recovering) regulatory loops act. Because the coupling action between the simultaneous processes is mutual, the total coupling effect actually forms closed feedback loops for each kinetic variable involved”. “There exists a well-established set of essential thermodynamic and kinetics pre-requisites for the occurrence of spontaneous oscillations”, as well as their consequences, extensively discussed by [42-46,59].

Table 2-C:Extended HSMDM model including the mass balance of the cell glycolytic key-species, and of the FBR control variables (inlet [GLC], inlet

feed flow-rate FL, and viable biomass X) for an optimally operated FBR (with time step-wise feeding policy, over j = 1,…, Ndiv equal time-arcs, and for

Ndiv =5). Adapted from [30,43-47,60]. Reaction rate expressions V1-V6 of the cell model, describing the dynamics of the cellular glycolytic species,

are those of the kinetic model of (Table 2-A) Maria [42,60], and of Chassagnole et al. [67]. See the notations of [30].

Footnote: (a) For the adopted Ndiv = 5, the j =1,…, Ndiv time-arcs approx. switching points are: T1= 12.5 h.; T2= 25 h.; T3= 37.5 h.; T4= 50 h.; = 63

hrs. The - time step-wise feed flow-rates are to be determined together with the other control variables (that is cfeedglc,j) to ensure the FBR optimal operation with maximizing the TRP production.

(b) The initial concentrations of cell species (F6P, FDP, PEP, PYR, ATP), and of the biomass are given in (Table 1).

“In the glycolysis case (Figures 2&3), oscillations are due to the

antagonistic action of two processes on regulating the V2 reaction

rate (i.e. the oscillation node).” [54-56,68]. The V2 lumped reaction

converts F6P in FDP (see the pink rectangle in Figure 2). Glycolytic

oscillations properties (period, amplitude) are determined by the

both external and internal (phenotype) factors. “According to Maria

et al. [42-59] the glycolysis dynamics (quasi steady-state QSS, transient,

or oscillatory) depends on several factors. Among them, are

to be mentioned the followings:

a) The glucose level in the liquid-phase {[GLC]ex}, which is determined

by the SBR/FBR operation conditions;

b) The efficiency and the dynamics of the whole ATP recovery

system. Among the involved parameters, an essential one is the

k6 rate constant (related to the ATP-ase characteristics in Figure

4). The involved enzymes characteristics are determined

by the cell phenotype (genom) controlling the total energy resources.

To not complicate our simulations, the [AMDTP] level

was kept unchanged in the present analysis at the value given

in (Figure 4), and in (Table 1).

c) As an important remark, “the glycolysis is a systemic process,

with a complex regulatory structure. Consequently, oscillations

are also related to the rate constants of the all involved

reactions, and their appropriate ratios (depending on the enzymes’

activity of each micro-organism)” [43,44,46,66].

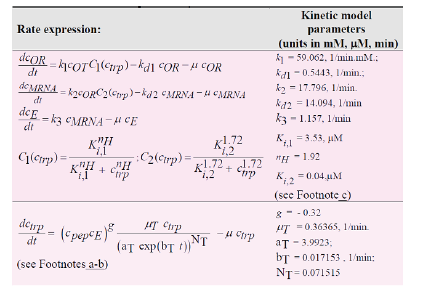

TRP synthesis (TRP-operon expression) model

“TRP is an aromatic non-polar α-amino-acid essential in humans, that is used in the cell biosynthesis of proteins, being also a precursor to the neuro-transmitter serotonin, of the melatonin hormone, and of vitamin PP [98]”. Therefore, maximizing its production via off-line in-silico (model-based) analyses is of particular industrial interest. “The TRP operon expression in E. coli is one of the most extensively studied molecular regulatory systems” [99]. The synthesis of excretable TRP is known as being an oscillatory process. However, due to the process high complexity, only reduced dynamic models involving lumped reactions/species are used, the regulatory performance being included in adjustable model terms and rate constants. In the present analysis, the in-silico analysis of the TRP synthesis was performed by using the lumped kinetic model of Maria et al [44,45,60]. This kinetic model is based on the simplified TRP synthesis scheme displayed in (Figure 3), derived from various studies reviewed by Maria et al. [44,45,60]. The adopted model for the TRP synthesis, presented in (Table 3), is a modification of the [64] model in order to better fit the experimental kinetic curves of the cell key species {OR, mRNA, T, E} [44], but also of the state-variables of a FBR [60,62] (Table 2B). Beside, the model was explicitly connected to the glycolysis (as displayed in Figure 3), by including in the TRP mass-balance ((dctrp/dt) in Table 3) a term accounting for the PEP precursor, while the PEP consumption term is included in the PEP balance of the MGM model (Table 2B). Other dynamic models for the TRP synthesis module are reviewed by Maria et al. [44].

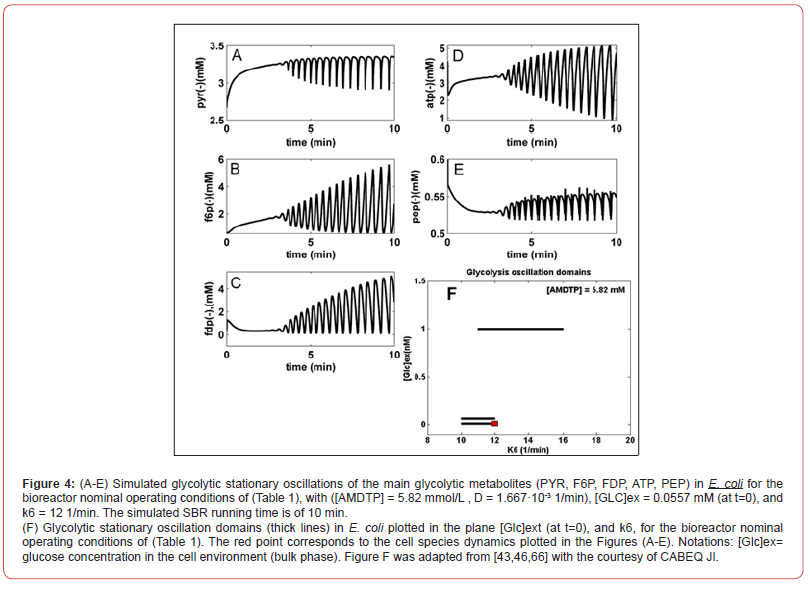

Glycolytic oscillations

Repeated simulations of the bioreactor dynamics with using

the SBR/MGM model, with the initial conditions of (Table 1) and

over the ranges of [GLC]ex Є [0.01-1.5] mM (at t=0), and k6 Є [10-5-

20] 1/min lead to the following conclusions [44-47]:

a) Several glycolytic stationary oscillations domains exist in the E.

coli cells, as indicated by the thick lines of (Figure 4-F) plotted

in the {[GLC]ex-vs.- k6} plane.

b) As resulted from (Figure 4-F), glycolytic stationary oscillations

occur for a slow GLC import due to a low [GLC]ex level in the

environment, but also due to small k6 constant values (that

corresponds to a low recovery rate of the ATP). Conversely,

higher concentrations of GLC in the bioreactor will trigger

higher GLC import rates. In this case, glycolytic oscillations are

also possible if the k6 constant reported large values (for a certain

K constant controlling the AMDTP pathway/equilibrium

given in Table 2-A). However, the ATP recovery rate is limited

by the AMDTP resources, and by the inter-conversion balance

of the AMDTP system (Figures 2&3, Table 2-A). As reported by

[44-47], in the cells with too small, or too large k6 values, the

glycolysis often reaches its (non-oscillatory) steady-state.

c) The glycolytic oscillation domains plotted in (Figure 4-F) are

very narrow. Such a result reflects their high sensitivity vs. lot

of external and internal factors. Besides, oscillations present

a poor stability vs. internal/external factors, as proved by the

plotted limit cycles (omitted here; see [43-47,66]). Experiments

in the literature have found that this stability is dependent

on the metabolism characteristics of every micro-organism.

For instance, by contrast, “the glycolytic oscillations in

yeast have been proved to be very robust even in the presence

of environmental noise, … oscillations being a side-effect of

the trade-offs between robustness and regulatory efficiency of

the … feedback control of the autocatalytic reaction network”

[100,101].

d) The simulation results indicated that larger values of k6 lead to

a slight decrease in the oscillation period and, eventually, the

oscillations disappearance. This is due to the quick consumption

of GLC by the cells following a more rapid ATP-recovery

system [43,66].

e) SBR dynamic simulations have identified glycolytic oscillations

with a period of 0.4-1 min, depending on the k6-value, and on

the [Glc]ex level [43-47]. For comparison, various experiments

in the literature have reported periods in a large range, that is:

“0.2 min. [69]; 2-100s [92]; 15s [53]; 1-20 min. [52], up to 3 h

[102], or 0.2min to hours [103].”

f) The simulated glycolytic oscillations of (Figure 4-B-C), (that

is FDP and F6P species) are similar to the experimentally recorded

dynamics by [104,105], and also similar to the dynamic

simulations of [89,52,106,107]. Figure 4(A-E) display an incipient

phase of the oscillation occurrence, when the species

oscillation amplitude grows. However, over a longer time domain

(not shown here), the oscillations stabilize and become

stationary.

g) The simulated [GLC]ex dynamics in the SBR proved that, for a

relatively high [GLC] = 200 mM in the feed, and for all the above

mentioned ranges of internal/external operating conditions,

the bioreactor evolution is always toward a steady-state (QSS),

with a faster or slower rate depending on the initial [GLC] in

the bioreactor, irrespectively to the cell metabolism (stationary/

homeostatic, or unbalanced) [43-47].

h) The factors influencing the glycolysis dynamics mentioned at

the end of chap. 2.5.1 are confirmed to have a major influence

on the glycolysis dynamics as proved by the present analysis.

TRP synthesis oscillations and their interference with the glycolytic oscillations

Under certain conditions, the TRP synthesis presents oscillations

[64]. Being strongly connected with the glycolysis (via PEP),

it is important to study the influence of the glycolytic oscillations

on the TRP synthesis dynamics. Such an analysis turns out to be of

high practical interest in order to adapt the bioreactor operation

to maximize the TRP production and, eventually, for the in-silico

design of GMO–s with such an objective (by modifying the cell metabolic

fluxes). In particular, the glycolysis intermediate PEP is the

starting point for the synthesis of essential amino-acids, including

TRP [81,108,109,110]. Having PEP as one of the precursors, maximization

of TRP synthesis clearly depends on the glycolysis intensity

(average levels of glycolytic species) and dynamics (QSS or oscillatory).

On the other hand, as previously discussed, glycolysis is

controlled by cell internal and external factors, which indirectly will

also influence the TRP synthesis, as follows:

a) The GLC import rate through the PTS-system (flux 50 in Figure

2) regulated and triggered by the environmental [GLC]ex, and

by the PEP and PYR levels into the cell (see V1 flux expression

in Table 2-A);

b) The limited ATP energy resources, and an ineffective/slow recovery

system can slowed down the GLC import, the glycolysis

and, implicitly, the all metabolic syntheses;

c) The bacteria genome (cell phenotype) plays an essential role,

because it determines the characteristics of the ATP-ase and

AK-ase enzymes (Figure 3) responsible for the ATP to ADP

conversion and for the ATP recovery rate during the glycolytic

reactions (modelled by means of the K and k6 rate constants in

the MGM kinetic model of Table 2-A). In fact, the efficiency of

the A(MDT)P inter-conversion system affects most of the metabolic

reactions.

d) Being a systemic process, inherently the glycolysis dynamics

(oscillations) are also related to the rate constants of all the

glycolytic reactions. As an example, Silva and Yunes [53] found

that oscillations are only possible if the [GLC]ex, and the maximum

reaction rates controlled by the PFKase and GKase are

within specific intervals. The GKase is one of the enzymes controlling

the V1 lumped reaction related to the PTS import system

(GLC to G6P and then to F6P in Figure 3 and Table 2A). The

PFKase controls the V2 reaction (of Figure 3, and Table 2A)

responsible for the FDP synthesis.

e) Following the results presented in the chap.2.5.3 (“Glycolytic

oscillations”), it is expected that, beside external parameters

(like [GLC]ex), also internal (like k6) to also influence the

TRP synthesis dynamics and performance. As has been proven

experimentally by Bhartiya et al. [64], the TRP synthesis is

an oscillatory process with a complex engine. In-silico (model-

based) analyses of Maria et al. [30,43-47,60] highlighted

some of the factors on which the dynamics and performance of

the TRP synthesis depends.

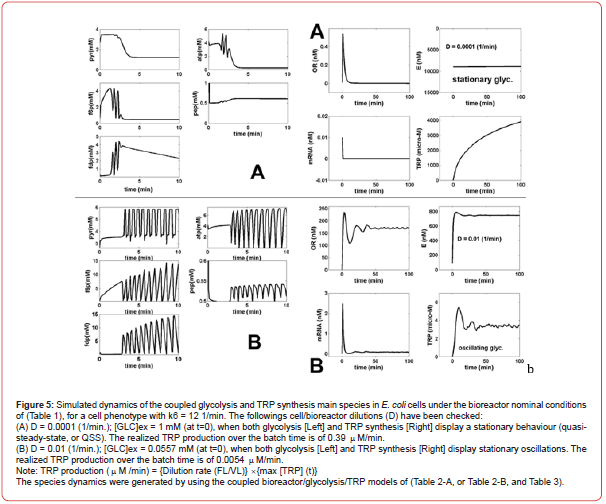

As mentioned by [99,111], “oscillations in the TRP synthesis are produced due to the concomitant activation and high order repression of the TRP-operon expression, together with a nonlinear demand for the end product, making its expresses to be cyclic.” Maria et al. [30,43-47,60] pointed-out through model-based simulations that the cell dilution rate (related to the cell cycle), adjusted to be quasi-even with the liquid residence-time in the bioreactor, also exerts a strong influence on the TRP system dynamics. Simulations of the present paper have been performed by using the SBR reactor model which includes the coupled glycolysis MGM model (Table 2-A), and the TRP synthesis kinetic model (Table 3). The sensitivity analysis of the TRP production was performed by considering some of the most influential parameters checked in the range of [GLC]ex [0.01-1.5] mM (at t=0), and k6 [10-5-20] 1/min, and D [10- 4 – 0.01] 1/min, with initial [GLC]ex [0.005-5] mM (at t=0). The simulation results for only two relevant operating conditions have been plotted in (Figures 4-A-B). This analysis lead to several results as follows: [30,43-47,60]

a) The [GLC]ex, the constant k6, and the bioreactor dilution D

(adjusted to be equal to the cell dilution) exert the highest

influence not only on the glycolysis dynamics, but also on the

TRP synthesis dynamics and production (due to its close link

to glycolysis through the common sharing node PEP). Thus,

under the initial SBR conditions of (Table 1), for a low SBR dilution

rate (D), and for conditions leading to a QSS glycolysis,

the TRP synthesis also displays a stationary evolution (Figure

5A). By contrast, at higher dilutions, and when glycolysis meets

the conditions necessary for an oscillatory process (of Figure

4F), the TRP synthesis also presents an oscillatory dynamic

(Figure 5B). Consequently, the bioreactor dilution presents a

strong influence on the QSS or oscillatory regime of the linked

glycolysis and TRP synthesis. The TRP production (see its definition

in the caption from Figure 5) is influenced accordingly.

A value of k6 = 12 min-1 was considered in all the tested

cases here. An exhaustive, or an adaptive model-based search

can identify the SBR operating conditions that correspond to a

maximum of TRP production [30,43-47,60].

b) While glycolysis exerts a strong influence on the TRP synthesis

dynamics, as proved by (Figures 5A-B), the reverse influence is

minor, as proved by disconnected glycolysis simulations (not

reproduced here).

c) The high feeding rates (D), or the high [GLC] in the feeding

solution of the SBR (Table 1), or high initial [GLC] in the bioreactor,

do not quantitatively influence the TRP bioreactor performances.

[30,43-47,60].

d) Simulations of the only TRP synthesis, disconnected from the

glycolytic process, but with employing various [PEP] average

levels [66], indicate that PEP average level has a huge influence

on the dynamics and concentrations of the TRP synthesis

species.

e) It clearly appears that, beside cell phenotype (defining for the

TRP operon expression), glycolysis is one of the major factors

influencing the TRP production. Thus, by ranging the SBR operating

parameters, the TRP production can be maximized

[30,43-47,60], as proved in the next chap. 3.

f) In all the SBR operating cases checked by Maria et al. [30,43-

47,60] with the initial conditions of (Table 1), but in the range

of D [10-4 – 0.01] 1/min, simulations demonstrated that the

[GLC]ex in the liquid always evolves toward its steady-state

(QSS) irrespectively of the stationary or oscillatory dynamics

of the cell metabolic processes (Figure 6).

As remarked by Silva and Yunes [53], glycolytic oscillations “are focused on the maintenance of energy levels in the cell (negative regulation of PFKase by ATP) and thus the ability to limit the conversion into energy in situations where it is not needed. Therefore, it would be more advantageous to store it or deviate the flux towards other cell cycle activities such as cell division. Consequently, mutant cells with modified enzymes activity (especially PFKase, PKase, ATPase, AKase of Figure 3) will lead to a noticeable modification in the metabolism, and TRP synthesis”.

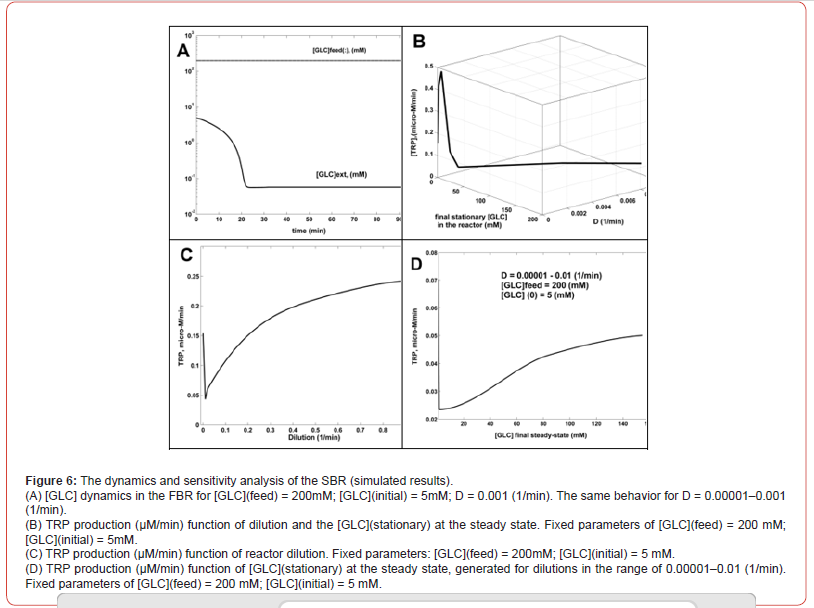

Engineering Implications-Sensitivity Analysis

Eventually, this in-silico analysis of the SBR by using the above

described HSMDM dynamic model suggests how to modulate these

most influential control variables and factors {[GLC]ex, via [GLC]

(feed), and [GLC](initial) D, k6 (via cell phenotype), and others} to

obtain an optimal operating policy of the SBR or of the FBR [e.g.

time step-wise variable feeding policy, in both feed flow-rate, and

[GLC](inlet), see the below chap 3] leading to maximization of the

TRP synthesis. An exhaustive or an adaptive model-based search

can identify the SBR optimal operating policy that corresponds to

a maximum of TRP production [30,43-47,60]. In the present study,

a quick sensitivity analysis based on the present model, revealed

several interesting conclusions, as followings: [30,43-47,60].

a) A larger number of SBR simulations with using various operating

parameters proved that SBR efficiency (TRP production)

is not influenced by [GLC](initial) < 100 mM in the bioreactor,

once [GLC](feed) > 100 mM.

b) In all tested cases covering the ranges [GLC](feed) of 100-200

mM, [GLC](initial) of 1-50 mM, D=0.00001–0.01 (1/min.),

the SBR evolves rapidly to its steady state, corresponding to

a small [GLC](stationary) < 1 mM (an example is displayed in

(Figure 6-A).

c) The TRP productivity increases with D, as plotted in (Figure

6-C).

d) The TRP productivity also increases with the [GLC]ex, as

plotted in (Figure 6-D), where external (bulk) concentration

is given by the steady-state level of the stationary [GLC]. The

combined dependency of TRP productivity on reactor dilution

and [GLC](stationary) is given in (Figure 6-B), confirming the

above conclusions (c-d), for a wide range of the reactor dilutions.

As proved in this work, the TRP productivity is also strongly dependent on the oscillatory characteristics of the glycolysis, determined by the above-mentioned operating parameters, and on the activity of enzymes involved in the ATP recovery system (that is the rate constants k6, K, and [AMDTP] of Table 2A). Thus, from the biological point of view, as mentioned by [53], “glycolytic oscillations are focused on the maintenance of energy levels in the cell (negative regulation of PFKase by ATP) and thus the ability to limit the conversion into energy in situations where it is not needed. Therefore, it would be more advantageous to store it or deviate the flux towards other cell cycle activities such as cell division. Consequently, GMO with modified enzymes activity (especially those related to the ATP use/recovery system of Figure 3) will lead to noticeable modifications in the metabolic species dynamics and concentrations.”

Conclusions

The in-silico analysis of this paper demonstrates “in a meaningful and relevant way the importance of using a detailed enough and adequate structured dynamic HSMDM model linking the metabolic cellular processes and the bioreactor state-variables for engineering evaluations of the target process performance. Such a modular hybrid model can link the macro-scale (bioreactor liquid-phase) process variables to the nano-scale (cellular) ones.”

The structured HSMDM model not only can be used for the SBR optimization, “but can also be a valuable tool to evaluate the cellular metabolic fluxes (i.e. the homeostatic metabolic reaction rates, not evaluated here), thus opening the possibility to in silico re-design the cell metabolism to obtain GMO-s with industrial or medical applications [1,2,4,5,20,30,32,43-47,60,75-77,112]. Thus, the large experimental and computational effort to validate such structured cell models is eventually fully justified through the practical advantages offered by such an engineering analysis. It is also to be emphasized that such a modular and structured approach of the dynamic cellular models via HSMDM offers the possibility to study the interference of the CCM sub-process (e.g. glycolysis, and AA synthesis here), together with the influence of the external conditions. Such a modular simulation platform presents the advantage to be easy to extend by the inclusion of new CCM modules.”

Case study no. 2. The Use of a HSMDM Modular CCM Cell-Scale Structured Kinetic Model Coupled with a FBR Dynamic Model (Including Macro-Scale State Variables) to in-Silico Off-Line Maximize the TRP Production

Abbreviations and notations used in this section 3

Generalities about the TRP synthesis bioprocess

In general, the HSMDM models can be further used as the core of a modular dynamic model used to simulate the CCM and regulation of various metabolite syntheses, with application to in silico reprogramming of the cell metabolism to design GMO of various applications [4,5,7,20,43,112]. One example, detailed in this section is the in-silico off-line optimization of the operating conditions of a fed-batch bioreactor (FBR) with GMO E. coli to maximize the production of tryptophan (TRP). Thus, compared to a simple batch bioreactor (BR) using a wild E. coli cell culture, the TRP production was increased with 73% (50% due to the novel design GMO E. coli strain, and 23% due to the model-based optimization of the variable feeding of the FBR) [30,43-47,60,66,] An exceptional example of multiple applications of extended structured HSMDM dynamic models is offered by Maria [30,60]. As exemplified in the Part-1, and Part-2 of this work, and by Maria [4,5,112] hybrid kinetic models, linking structured cell metabolic processes to the dynamics of macroscopic variables of the bioreactor, are more and more used in the engineering evaluations to derive more precise predictions of the process dynamics under variable operating conditions. Depending on the cell model complexity, such a math tool can be used to evaluate the metabolic fluxes in relationships to the bioreactor operating conditions, thus suggesting ways to genetically modify the micro-organism for certain purposes. Even if development of such extended dynamic MSDKM or HSMDM models requires more intensive experimental and computational efforts, their use is advantageous, as proved by the Parts 3 and 4 of the work, and by the examples offered by [4,5,112].

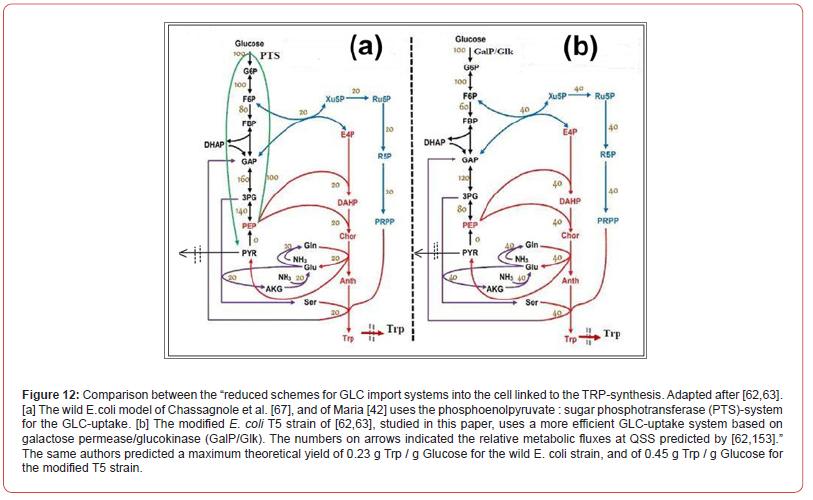

The approached probative example of this section refers to a

HSMDM model able to simulate the dynamics of nano-scale variables

from several pathways of the central carbon metabolism

(CCM) of E. coli cells, linked to the macroscopic state variables of a

fed-batch bioreactor (FBR) used for the tryptophan (TRP) production.

Based on this model, and other classical in-vitro rules, the used

E. coli strain was in-silico, and experimentally modified to replace

the PTS-system for glucose (GLC) uptake (Figure 12) with a more

efficient one, based on galactose permease/glucokinase (GalP/Glk).

The study, detailed by [30,60] presents multiple elements of novelty,

as summarized as follows:

a) The experimentally validated modular HSMDM model itself,

and

b) Its efficiency to in-silico derive an optimal operation policy of

the studied FBR, with a higher accuracy compared to the classical

empirical (heuristically) optimization rules using apparent

unstructured kinetic models of the bioprocess [7,9,62].

Over the last decades, there is a continuous trend to develop more and more effective bioreactors [9,80] to industrialize important biosyntheses for producing fine-chemicals used in the food, pharmaceutical, or detergent industry, by using free-suspended or immobilized cell cultures in suitable bioreactors, as reviewed by Maria [7]. The batch (BR), semi-batch (SBR), fed-batch (FBR), or a serial sequence of BR-s [116], or the continuously operated fixed-bed, or three-phase fluidized-bed bioreactors (with immobilized biocatalyst), etc., are successfully used to conduct biosyntheses aiming to replace complex chemical processes, energetically intensive and generating toxic wastes [6,7,24,45,60]. Among applications, it is to mention fermentative processes for production of organic acids, alcohols, vinegar, amino-acids (TRP, cysteine, lysine, etc.), proteins, yeast, hydrogen, food products, and food additives [14,117], recombinant proteins (monoclonal antibodies) [7], etc., by using bioreactors with microbial (cell) cultures, or enzymatic reactors [6,9], by integrating genetic and engineering methods [18,19].

Bioreactors with microbial / animal cell cultures (suspended or

immobilized) have been developed in simple or complex constructive

/ operating alternatives as reviewed by [7,14,118], to mention

only few of such review works. In spite of their larger volumes, the

continuously mixing aerated tank reactors (CSTR), operated in BR,

SBR, FBR, or continuous modes, are preferred for bioprocesses

requiring a high oxygen transfer, and a rigorous temperature/pH

control. This is why; an effective FBR was used in the approached

case study for TRP production, as being more flexible as operating

regime alternatives. From the engineering point of view, in addition

to the production capacity optimization, there are several important

problems to be addressed, that is:

a) The key-point in screening among bioreactor alternatives and

operating modes. The answer to this problem is related to the

maintenance of the bioprocess optimal conditions that ensure

a high biomass activity (free or immobilized on a suitable porous

support), by supporting its growth to compensate its natural

biodegradation, and the risk to disintegrate the biomass

flocks or the support through mechanical shearing induced by

the mixing, thus leading to the biomass leakage and washout.

b) Development of optimal operating policies of the adopted/given

bioreactor, based on an available process dynamic (kinetic)

model (extended or reduced) derived from on-/off-line measurements.

The model-based optimal operation of the bioreactor can be

applied in two ways:

1. ’off-line’, in which an optimal operating policy is in-silico determined

in-advance by using an adequate kinetic model (usually a

deterministic one, based on the process mechanism), previously

identified from separate experiments; in this alternative, extended/

complex dynamic models of the bioprocess/bioreactor of HSMDM

type can be used, not being restricted by the ’real-time’ application,

and

2. ’on-line’, with using an extremely simplified dynamic model (an

apparent/global empirical one, often of a simple polynomial form)

of the bioprocess/bioreactor, and a classic state-parameter estimator,

based on the on-line recorded data.

Of course, the alternative (2), even if simpler and with a ’real- time’ application is very approximate, being often inadequate, thus requiring laboriously frequent (during bioreactor operation) empirical model updating [31,119-123].

The current (default) approach to solve the model-based design, optimization and control problems of the industrial biological reactors is the use of unstructured (global) models of Monod type (for cell culture reactors) or of Michaelis-Menten type (if only enzymatic reactions are retained) that ignores detailed representations of cell processes [4,5,8,9,124-126]. See an example given by Maria [4,5,37-40] for the mercury uptake in a fluidised-bed bioreactor using immobilized GMO E. coli. As underlined in the Part-1 of this work, the applied engineering rules are similar to those used for chemical processes (CBE), and inspired from the NSCT [4,31,124- 134]. However, by accounting for only key process variables (biomass, substrate and product concentrations), these global kinetic models do not properly reflect the metabolic changes, being unsuitable to accurately predict the cell response to environmental perturbations by means of (self-) regulated cell metabolism. The alternative is to use structured kinetic models, by accounting for cell metabolic reactions and component dynamics. Such deterministic models lead to a considerable improvement in the predictive power, with the expense of incorporating a larger number of species mass balances including parameters (rate constants) difficult to be estimated from often incomplete data and, consequently, difficult to be used for industrial scale purposes [1,2,4,5,37-40,135,136].

An alternative compromise, tested in the Parts 3 and 4 of this work, and by Maria [4,5,112], is to use hybrid dynamic math models, that is MSDKM and HSMDM models presented in the Part-1, and Part-2 of this work, developed by similarity to those used in the CBE, and in NSCT. These HSMDM models combine unstructured with structured process characteristics, linked to the macroscopic state variables of the bioreactor dynamic model, to generate more precise predictions of both cell nano-level state-variables, and macro- level bioreactor state-variables [1,2,4,5,37-40,137,138]. The idea of hybrid kinetic models is to inter-connect groups of process variables belonging to at least two hierarchical levels of model details. The resulted composite (hybrid) model is able to simulate the bioreactor dynamics simultaneously at various levels of detail. Thus, the dynamics of the bioreactor macroscopic state variables (i.e. species present in the liquid bulk) is simulated concomitantly to the nanoscopic variables describing the cell metabolic processes of interest, because the macro-/nano-scale variables are closely linked, as long as some cell metabolites are imported/excreted from/in the bioreactor bulk. Even if such a complex / extended dynamic model, including some complex cell metabolic pathways requires more experimental and computational efforts to be builtup and identified from structured kinetic data, the resulted hybrid (bi-level, macroscopic and nanoscopic) dynamic model presents major and remarkable advantages, as listed (no. i-ix) and discussed in the Part-1 of this work [4].

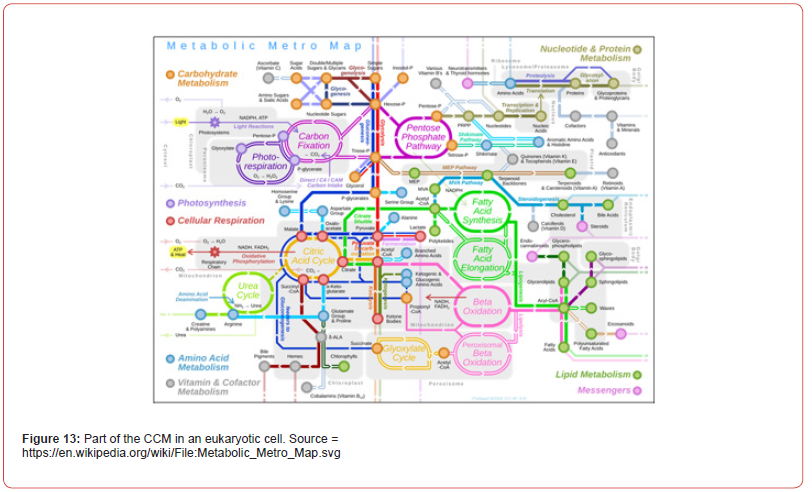

In fact, such a MSDKM hybrid structured cell dynamic model must include only the essential parts of the CCM (Figures 2, 13-17] by incorporating the pathway responsible for the target metabolite synthesis, and the lumped modules of the cell core, that is: the glycolysis, the GLC uptake system [i.e. the phosphotransferase (PTS), or an equivalent system, such as those based on the galactose permease/glucokinase (GalP/Glk)], the ATP-recovery system, the pentose-phosphate pathway (PPP), the tricarboxylic acid cycle (TCA), and other metabolic pathway modules (if necessary in simulations). See, for instance, [41,43-45,139] for more details.

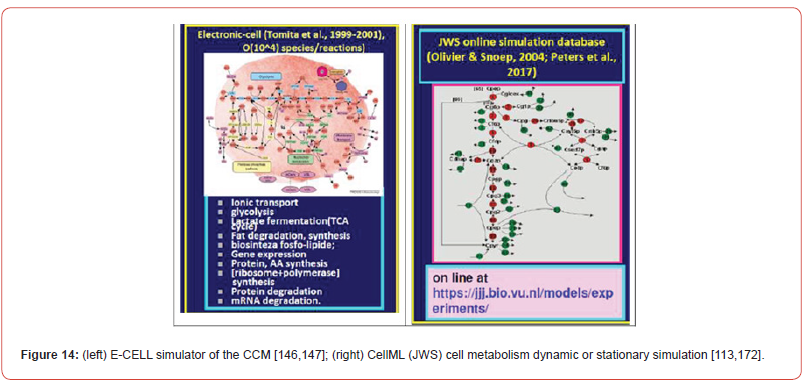

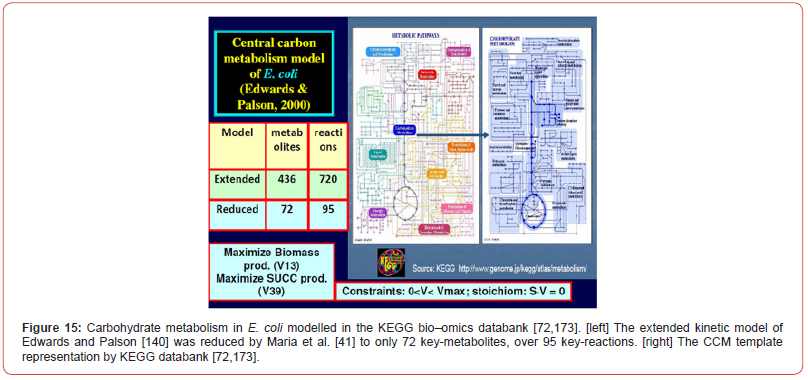

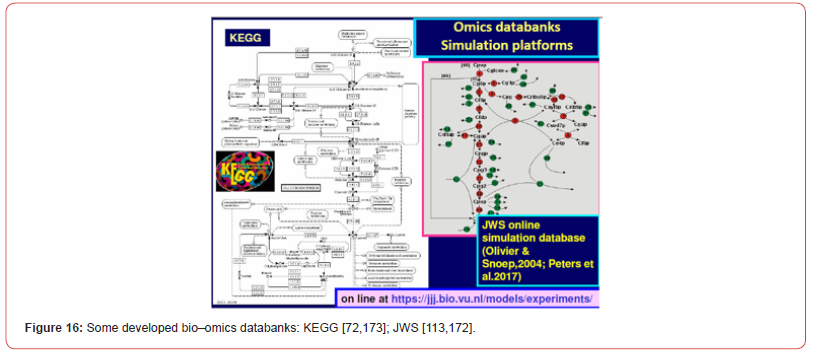

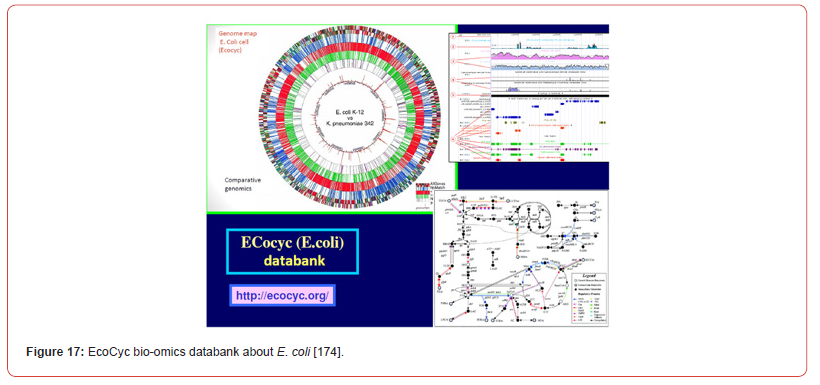

A special interest has been granted to the accurate modelling of the glycolysis dynamics and its self-regulation [42,43,46,66] as long as most of the glycolysis intermediates are starting nodes for the internal production of lot of cell metabolites (e.g. amino-acids, SUCC, CIT; TRP) [7,41,44,45,60,]. This needs to have good quality MSDKM structured cell models to simulate the dynamics (and regulation) of the bacteria CCM became a subject of very high interest over the last decades, allowing in-silico design of GMO-s with desirable characteristics of various applications [1,2,4,5,135]. As a result, an impressive large number of valuable structured deterministic models (based on a mechanistic description of the metabolic enzymatic reactions tacking place among individual or lumped species) have been proposed in the literature to simulate the cell CCM dynamics, with including tenths-to-hundreds of key species. Here, it is worth mentioning the E. coli model of Edwards and Palsson [140] used by Maria [41,42,67,71,141-143] for various purposes, or the S. cerevisiae glycolysis model of Teusink et al. [144], or the JWS platform of Olivier and Snoep [113], and the MPS platform of Seressiotis and Bailey [145] to simulate cell metabolism (dynamics and/or fluxes), to mention only few of them. Simulation platforms, such as E-cell [146,147], or V-cell [148], accounting for thousands of species and reactions, display extended capabilities to predict the dynamics of the cell metabolism under various conditions, based on EcoCyc, KEGG, Prodoric, Brenda and other bio–omics databanks (review of Maria [1,2,4,5,135]). A worthwhile CCM-based dynamic or stationary models were reported by Maria [4,5,41,42,60] and schematically represented in (Figures 2, 13-17). Deterministic MSDKM kinetic models using continuous variables has been developed by Maria [42] for the glycolysis, and by [61,67,94-96,149] for parts of the CCM. Such models can adequately reproduce the cell response to continuous perturbations, the cell model structure and size being adapted based on the available bio–omics information.

In spite of such tremendous modelling difficulties, the development of structured reduced deterministic (rather than stochastic) models [1,2,4,5] able to adequately reproduce the dynamics of some CCM complex metabolic syntheses [42,77,76], but also the dynamics of the genetic regulatory circuits (GRC-s) [1,2,4,5] tightly controlling the metabolic processes reported significant progresses over the last decades [150,151]. Even if they are rather based on sparse information from various sources, unconventional statistical identification, and lumping algorithms [1,2,4,5,86-88], such MSDKM structured reduced deterministic kinetic models have been proved to be extremely useful for in-silico analyse and characterize the cell CCM, dynamics, but also the stationary metabolic fluxes, useful for designing novel GRC-s and GMO-s conferring new properties/ functions to the mutant cells [1,2,4,5,152].

In spite of such tremendous modelling difficulties, the development of structured reduced deterministic (rather than stochastic) models [1,2,4,5] able to adequately reproduce the dynamics of some CCM complex metabolic syntheses [42,77,76], but also the dynamics of the genetic regulatory circuits (GRC-s) [1,2,4,5] tightly controlling the metabolic processes reported significant progresses over the last decades [150,151]. Even if they are rather based on sparse information from various sources, unconventional statistical identification, and lumping algorithms [1,2,4,5,86-88], such MSDKM structured reduced deterministic kinetic models have been proved to be extremely useful for in-silico analyse and characterize the cell CCM, dynamics, but also the stationary metabolic fluxes, useful for designing novel GRC-s and GMO-s conferring new properties/ functions to the mutant cells [1,2,4,5,152].

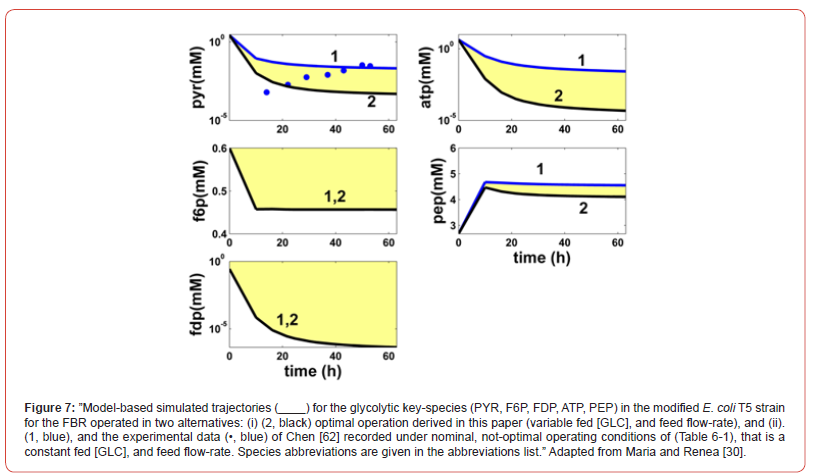

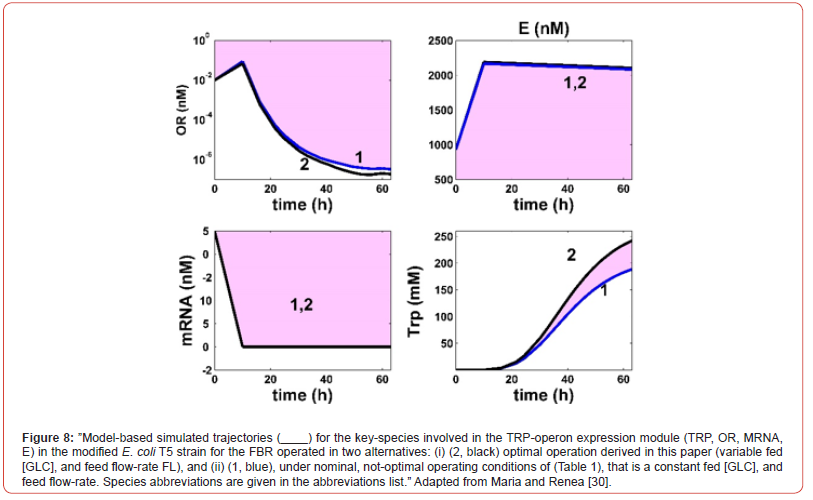

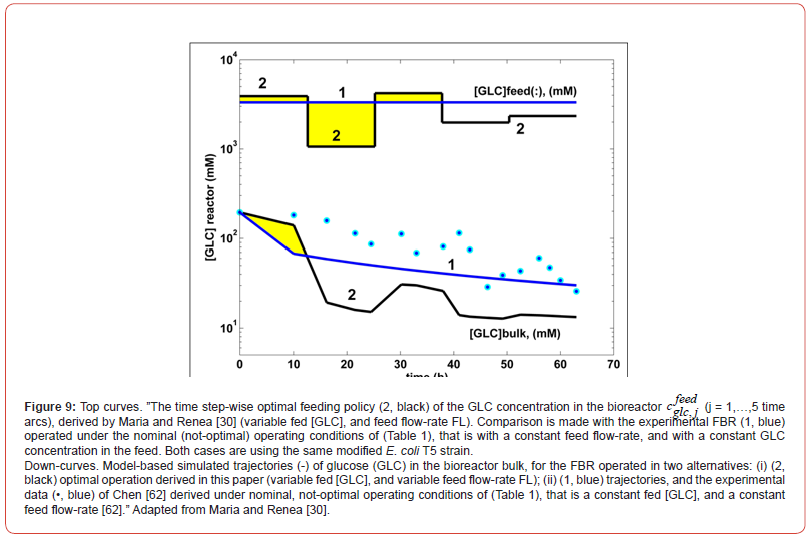

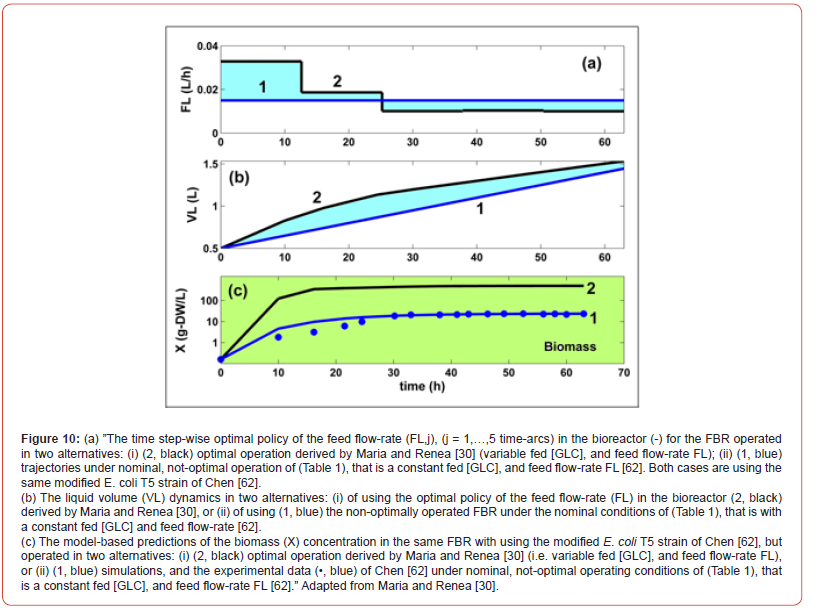

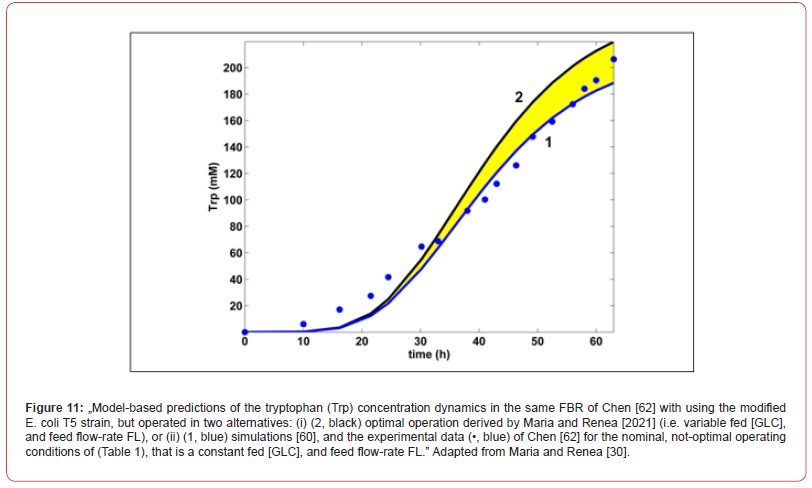

The case study presented in this chapter uses a hybrid dynamic

HSMDM model built-up by [60] by linking a CCM-based structured

kinetic model with a FBR ideal dynamic model. The resulted hybrid

(bi-level) FBR model was used to in-silico determine the optimal

(time step-wise) feeding policy of the FBR used by Chen et al. [63]

to study the TRP-synthesis by using a genetically modified design

E. coli T5 strain culture. The thus obtained optimal operating policy

of the FBR has proven to be very effective, by ensuring maximization

of the TRP production with involving only two key control

variables, that is:

a) The variable feed flow-rate FL,j (j = 1,…, Ndiv), and

b) The variable feeding GLC concentration cfeedglc,j (j = 1,…,

Ndiv)

Where Ndiv = 5 are the ’time arcs’, that is the equal time-intervals

in which the batch-time (tf) was divided. During each ’time-arc’

(of equal lengths), the control variables are kept constant at optimal

values determined from solving the below described optimization

problem (i.e. maximization of the TRP production in this case).

The obtained optimal operating policy of the approached FBR, by

using the extended HSMDM model, reported better performances

compared to the not-optimally operated FBR of Maria [45,60], or of

Chen [62]. The structured modular kinetic model of Maria [42,60]

used in this numerical analysis includes four inter-connected modules

characterizing the dynamics of the concerned cell CCM-pathways

involved in the TRP-synthesis, that is:

a) Module [A] – glycolysis (inside cell);

b) Module [B] – ATP recovery system (inside cell);

c) Module [C] – TRP synthesis (that is the TRP-operon expression

inside cell);

d) Module [X] – the suspended biomass growth (outside cell).

This cellular structured bioprocess HSMDM model was experimentally identified, and checked over extensive experiments conducted by several authors, that is [42,43,67,76] for the glycolysis, and by Chen et al. [62,63], and by Maria [60] for the TRP synthesis. Experimental data of Chen [62] for the TRP-synthesis are also used to validate the predictions of the hybrid HSMDM model [30,60].

The present study presents multiple elements of novelty, as followings:

a) Although production of TRP by engineered E. coli has been extensively

studied, the need of multiple precursors for its synthesis

and the complex regulations of the biosynthetic pathways

make the achievement of a high product yield still very

challenging [60]. This engineering problem was solved here by

using a model-based (in-silico) approach, completed with a biological

improvement of the used E. coli cell culture;

b) The derived optimal operating policy of the FBR is given on

time-intervals (the so-called ‘time-arcs’) of equal length, and of

a reduced number to be easily implemented. The control variables

present optimal but constant levels over each time-arc

(different between time-arcs) during the FBR operation.

c) The used biomass culture refers to a GMO E. coli T5 strain. The

characteristics of this strain were reflected in the rate constants

estimated by Maria [60]. This T5 strain was produced by

[63,153] to increase the TRP production in their bench-scale

FBR. Chen et al. [62,63,153] performed genetic modifications

of the TRP producer ’wild’ strain S028. Basically, by using a

simplified MSDKM model, to determine the key-fluxes of interest

(Figure 12) they remove the PTS import-system of GLC of

the ‘wild’ strain by replacing it with a more effective one based

on the galactose permease/ glucokinase (GalP/Glk) uptake

system, by modulating the gene expression of GalP/Glk. The

resulted T5 strain showed an increase of the specific TRP production

rate in a non-optimal FBR by 52.93% (25.3 mg/gDW

biomass /h) compared to the initial strain [63], and by ca. 70%

if the used FBR is optimally operated (this case study).

d) The below simulations with the extended HSMDM model of

Maria [30,60] reveal the close link between the cell key-metabolites

dynamics and the FBR operating conditions.

e) The used hybrid bi-level kinetic HSMDM model is enough

complex to adequately represent the dynamics of the FBR

state-variables, that is: the biomass [X] growth in the bulkphase,

the GLC depletion in the bioreactor liquid-phase, the

excreted TRP dynamics in the bulk-phase, and the dynamics of

the excreted PYR, but also the dynamics of the cell key-species

involved in the concerned reaction pathway modules, that is:

a) Glycolysis,

b) Atp-recovery system,

c) Trp-operon expression.

The design/checked E. coli GMO strain