Mini Review

Mini Review

Method for Reducing Energy Consumption in Cotton Ginning

MM Agzamov1*, Sh Sh Khakimov2, Kh M Nosirov3, Z N Agzamova4 and A S Khamidov5

2Professor of the department “Technological machines and equipment”, Tashkent institute of textile and light industry, Uzbekistan

3Researcher of the department “Technological machines and equipment”, Tashkent institute of textile and light industry, Uzbekistan

4Researcher, designer of UZ-KOR Technopark, Uzbekistan

5Lecturer of the department “Labor protection and ecology”, Tashkent institute of textile and light industry, Uzbekistan

MM Agzamov, docent of the department “Technological machines and equipment”, Tashkent institute of textile and light industry, Uzbekistan.

Received Date: November 21, 2022; Published Date:December 09, 2022

Abstract

The article presents the results of research on finding ways to reduce energy costs in the process of saw ginning. There is information on the development of an installation for determining the coefficient of friction of raw cotton on a steel surface and the values of the speed of movement of raw cotton determined by experimental studies at various temperatures of the steel surface.

Introduction and Preliminaries

As is well known, at present, saving electricity is one of the priorities of all types of production where it is consumed.

In the technological process of primary processing of raw cotton, one of the main transitions is ginning. In a saw gin, the main amount of electricity consumed is accounted for by overcoming the forces of friction of the raw roller against the inner surface of the working chamber and the forces of separation of the fibers from the seed. Thus, it can be noted that a decrease in the friction force of the raw roller on the inner surface of the working chamber leads to energy savings [1-3].

In order to reduce the friction of the raw roller on the inner surface of the working chamber, a working chamber of the saw gin was developed with heating of these surfaces, because with increasing temperature, the coefficient of friction of fibrous materials on the steel surface decreases [4-6].

Materials and Methods

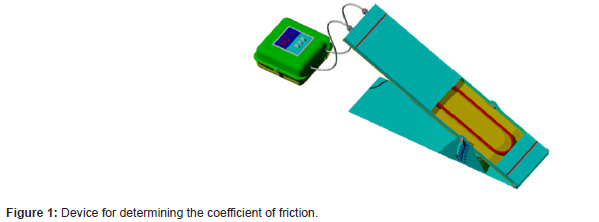

In connection with the above, it became necessary to conduct research to determine the change in the coefficient of friction of a fibrous material on a steel surface at different surface temperatures [7-9]. For this, a device was created to implement the proposed method (Figure 1).

The method is carried out as follows: for greater purity of experiments, the sample is preliminarily cleaned from trash. After that, they are installed on the marked point of the start of movement on an inclined surface preheated to the required temperature. After that, a flat weight is applied to the sample and movement is reported. In this case, the time of movement of the sample from the beginning of the point of movement to the end point of movement is fixed and the coefficient of friction is calculated [10-12].

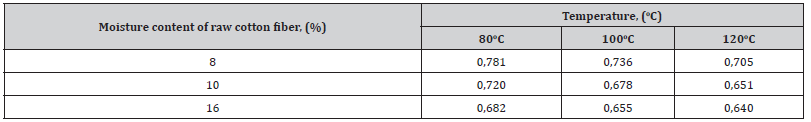

Table 1: Number of Subjects at Each Site.

Results

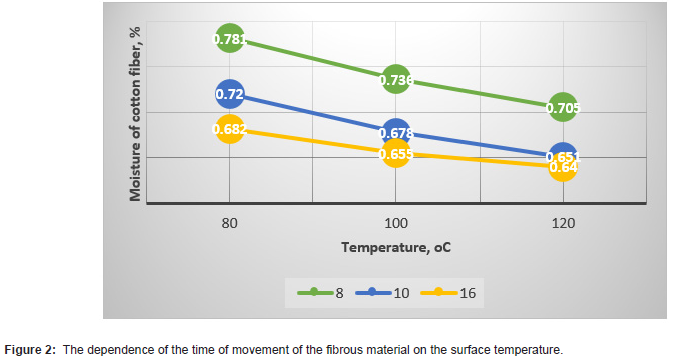

As can be seen from the tables and graphs, with increasing surface temperature, the time of movement of the fibrous material along the inclined surface decreases, which indicates an increase in the speed of movement due to a decrease in the friction forces between the fibrous material and the surface.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Agzamov M (2007) Studing of new gin stand with small size ginning box. Izvestia-Higher Educational Institutions Technology of the Textile Industry pp: 1-26.

- Agzamov M, Agzamov M M, Madgidov G F (2007) Ways for improvement of cotton fiber quality in process of ginning. Izvestia-Higher Educational Institutions Technology of the Textile Industry pp: 3-34.

- Makhkamov R G, Agzamov M (2006) Sampling quenching parameters of ginning and linter grid bars. Izvestia-Higher Educational Institutions Technology of the Textile Industry pp: 2-101.

- Agzamov M M (2021) The Influence of the Rotation Speed of the Raw Roller on Fiber Quality and Other Indicators of the Generation Process. In Proceedings of Higher Education Institutions. Textile Industry Technology 4: 88-93. Ivanovo State Polytechnic University.

- Razhabov, Ibrat Safoyev, Abdukhalil Agzamov, Mirkhosil Yuldashev, Djaloliddin, et al. (2020) Cleaner of Raw Cotton with a Screw Working Body. Saudi Journal of Engineering and Technology 5: 361-365.

- Yunusov Salokhiddin Agzamov, Mirsalikh Agzamov Mirkhosil, Kamolov Najmiddin, Khanimkul (2020) Influence of Ginning for Paddle Roll Speed Raw Roller Saw Gin. Test Engineering and Management 83: 3908-3917.

- Agzamov M, Rakhmatov M, Agzamov M, Olimov O, Nosirov K, et al. (2021) Search for ways to increase yield and improve product quality in the process of saw ginning. In IOP Conference Series: Earth and Environmental Science 939(1): 012073. IOP Publishing.

- Agzamov M, Radjabov I, Yuldashev D (2021) Research of the reasons of increased drop in cotton seeds after generation with reduced density of raw roller. In IOP Conference Series: Earth and Environmental Science 939(1): 012072. IOP Publishing.

- Sultonov A, Agzamov M, Rakhmatov M, Agzamov M, Nosirov K, et al. (2021) Development of the saw cylinder for gins and linters with use of new elements of the design. In O Tursunov (Ed.), E3S Web of Conferences 304: 03029. EDP Sciences.

- Yunusov S, Sultonov A, Rakhmatov M, Bobomurotov T, Agzamov M (2021) Results of studies on extending the time operation of gin and linter grates. In O Tursunov (Ed.), E3S Web of Conferences 304: 03028. EDP Sciences.

- Agzamov M M, Yunusov S Z, Gafurov J K (2017) On the technological development of cotton primary processing, using a new drying-purifying unit. In IOP Conference Series: Materials Science and Engineering 254(8): 082017. IOP Publishing.

- Agzamov Mirsolikh, Bakhtiyarovich, Rakhmatov, Agzamov Mirkhosil (2019) The Results of Research to Determine the Parameters of Hardening Working Area of the Gin and Linter Grates. Journal of Mechanical Engineering Research 2: 23-25.

-

MM Agzamov*, Sh Sh Khakimov, Kh M Nosirov, Z N Agzamova and A S Khamidov. Method for Reducing Energy Consumption in Cotton Ginning. Annal Biostat & Biomed Appli. 5(1): 2022. ABBA.MS.ID.000601.

Human organism, Living structures, Eukaryotic cells, Bacteria, Genomes, Cytoplasm

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.