Review Article

Review Article

Silage and Enzyme Additives as Animal Feed and Animals Response

Mebrate Getabalew1, Asebu Mindaye2 and Tewodros Alemneh3*

1Holland Dairy Private Limited Company, Milk Collection Point Coordinator, Debre Zeit, Ethiopia.

2College of Agricultural and Natural Resources Science, Department of Animal Science, Debre Berhan University, Ethiopia.

3Woreta Town Office of Agriculture and Environmental Protection, South Gondar Zone, Amhara Regional State, Ethiopia

Tewodros Alemneh, Woreta Town Office of Agriculture and Environmental Protection, South Gondar Zone, Amhara Regional State, Ethiopia.

Received Date: May 12, 2022; Published Date: September 21, 2022

Abstract

Silage making process can be explained very simply, it is actually very complex and dependent on many factors, such as the natural microbial population, harvesting conditions and the sugar content of the forage. Consequently, silage quality can be very variable and the only way to effectively control the fermentation process is to use an additive. Additives are natural or industrial products added in rather large quantities to the forage or grain mass. Additives control or prevent certain types of fermentation, thus reducing losses and improving silage stability. In order to assist in the fermentation process, various silage additives have been used to improve the nutrient and energy recovery in silage, often with subsequent improvements in animal performance. The purpose for applying additives to the silage is to ensure that the growth of lactic bacteria predominates during the fermentation process, producing lactic acid in quantities high enough to ensure good silage. Therefore, this review is made to focus on some practical aspects of the fermentation process and the uses of some common silage additives that include microbial inoculants, enzymes, and prop ionic acid. For smallholder farmers with limited production capacity, finding enough feed in the winter months to maintain good milk production is always a problem. Many are forced to buy hay, concentrates or silage just to keep their animals alive and are unable to benefit due to the higher prices paid for animal feed in the winter months. Silage making is long practiced by the larger agricultural sector, but the production method relies on heavy equipment and large production, in order to dig or build storage pits and to compress the green mass, putting it beyond the reach of smallholder farmers. Lactic acid is produced when the sugars in the forage plants are fermented by bacteria in a sealed container (‘silo’) with no air. Forage conserved this way is known as ‘ensiled forage’ or ‘silage’ and will keep for up to three years without deteriorating. Silage is very palatable to livestock and can be fed at any time.

Keywords:Silage; Silage additives; Enzymes; Fermentation; Inoculants; Lactic acid; Bacteria; Palatable; Concentrates

Introduction

Silage is the best method for preserving fresh forage with minimal losses. Silage quality and nutritional value are influenced by numerous biological and technological factors, when the proper ensilage techniques are used, silage will have a high nutritive value and hygienic quality [1]. However, the different results indicate that the quality of silage is often poor or even unsatisfactory. These results are usually achieved when the fermentation condition are difficult [2]. Factors which influence fermentation include degree of green fodder wilting, length of cut, ensiling technology type, and amount of an additive used [3].

Silage additives are natural or industrial products added in rather large quantities to the forage or grain mass. The purpose of silage additives is to control the preservation process so that by the time of feeding it has retained as many of the nutrients present in the original fresh forage as possible and to ensure that the growth of lactic bacteria predominates during the fermentation process, producing lactic acid in quantities high enough to ensure a good silage [3]. However, the exact nutrient status of the silage will depend on many factors that can only be controlled via management. It is important to remember that silage additives will not make poor quality forage into good silage, but they can help make top quality forage into excellent quality silage [4].

Many different silage additives are available and are used for different reasons. It includes fermentation stimulants, fermentation inhibitors, aerobic deterioration inhibitors, nutrients and absorbents [5]. Their main functions are to either increase nutritional value of silage or improve fermentation so that storage losses are reduced. Based on the above information, different authors described about the purpose of silage additives that can be used to ensure silage quality by encouraging lactic acid fermentation, by inhibiting undesirable microbes or by improving its nutritional value. The objective of the review paper is to know silage, silage additives, enzymes, fermentation, inoculants and also how to improve low quality feed by using silage and enzymes additives.

Literature Review

Silage

Silage can be defined as any plant material that has undergone fermentation or “pickling” in a silo. And a silo is any storage structure in which green, moist forage is preserved. The primary goal of making silage is to maximize the preservation of original nutrients in the forage crop for feeding of livestock at a later date in livestock feeding programs [6].

Principles of ensiling

Ensilage or ensiling is a process of preserving forage for later use as animal feed [6]. The principles of ensilage are well known. The first essential objective is to achieve anaerobic conditions under which natural fermentation can take place. Where oxygen is in contact with herbage for a period of time, aerobic microbial activity occurs and yeast and mould will grow. This causes the material to decay to a useless, inedible and frequently toxic product. Finer chopping of plant material results in improved compaction and fermentation of silage. This then improves palatability and intake of silage [7].

The second objective is to discourage the activities of undesirable microorganisms such as clostridia and enterobacteria. Clostridia are present on crops and in the soil in the form of spores. Clostridia multiply under anaerobic conditions, produce butyric acid and break down amino acids resulting in silage with a poor palatability and lower nutritional value. The enterobacteria are no-spore forming, facultative anaerobes, which ferment sugars to acetic acid and other products. Enterobacteria also have the ability to degrade amino acids [7].

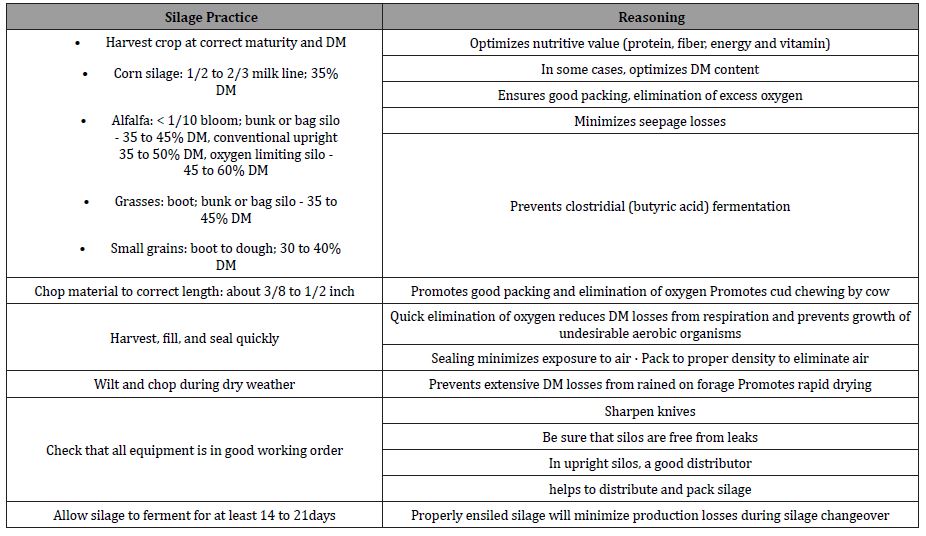

Growth of clostridia and enterobacteria can be inhibited by lactic acid fermentation. Lactic acid bacteria are normally present on harvested crops and these organisms ferment naturally occurring sugars like glucose and fructose to mainly lactic acid. The lactic acid produced increases the hydrogen ion concentration and undissociated acids to a level at which undesirable organisms are inhibited (Table 1) [7].

Table 1: Some good silage management practices.

Silage additives

Silage fermentation is a dynamic process that is affected by variety of factors. Research on silage and silage additives has been conducted for many years to improve the nutritive value of silages and to reduce some of the risks during the ensiling process [8]. A silage additive should be safe to handle, reduce DM losses, Silage additives are added to the forage or crop at ensiling, may improve the ensiling (fermentation) process, reduce losses, reduce aerobic deterioration at feed out, improve the hygienic quality of the silage, limit secondary fermentation, improve aerobic stability, increase the nutritive value of the silage, as the result increase animal production and give the farmer a return greater than the cost of the additive [8].

Some silage additives may also reduce unavoidable losses particularly those associated with the plant enzymes and microorganism or field losses. Examples of the five main classes of silage additives are fermentation stimulants (bacteria culture and carbohydrate sources), fermentation inhibitors (acids, formaldehyde), aerobic deterioration inhibitors (lactic acid bacteria, prop ionic acid), nutrients (urea, ammonia) and absorbents (barley, straw) [8,9].

Fermentation and animal response

The selection of the right biological silage additive will be made taking into account some rules. The amount of water-soluble carbohydrates necessary to obtain sufficient fermentation depends on the dry matter content and the buffer capacity of the crop.

In high dry matter silages with reduced water availability the presence of suitable, osmo tolerant lactic acid bacteria could become a limiting factor in the ensiling process. It has been shown that these bacteria represent only a small percentage of the indigenous micro flora on forage crop [9].

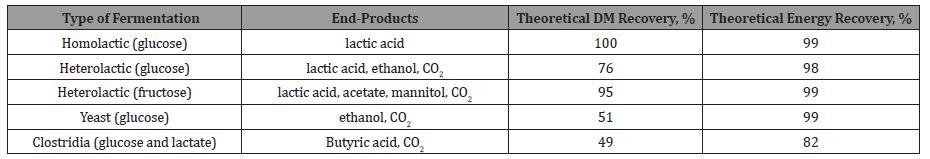

Lactic and acetic acids are major components of fermentation that are responsible for the increase in acidity of ensiled biomass (Table 2) [9]. Silages treated with lactic acid bacteria resulted in highest amount of organic acids and lowering final pH value improved the qualitative parameters of the silage compared with control. The silages treated with biological additives had also lower cell wall components (NDF, ADF) than silages control. Alfalfa, grass, and small cereal grain crops have responded well to microbial inoculation with hoLAB (Table 2) [9].

Table 2: Predominant fermentation pathways in silage.

Inoculation Rate, Use and Storage

Microbial inoculants can be applied to the forage at a variety of locations. However, application to forage at the chopper is highly recommended in order to maximize the time that microorganisms have in contact with fermentable substrates. Application at the chopper is more important if silage is being stored in a bunk or pile because it is difficult to achieve good distribution onto silage from a forage wagon [10].

Inoculants can be applied in a liquid or solid form. According to Dawson [10] reported that on higher DM silages (greater than about 45% DM), using a liquid based inoculant is preferable because the low moisture in these silages limits fermentation. Inoculants applied in a liquid form may be more advantageous because the bacteria are added with their own moisture to help speed up fermentation.

Storage is an important aspect of a high-quality inoculants that contains live microorganisms. Some inoculants require refrigeration or freezing for optimum storage. Those that do not require cold temperatures for storage should still be kept in cool, dry areas away from direct sunlight. Moisture, oxygen and sunlight can decrease the stability of inoculants resulting in lower viable counts and a product that does not meet label guarantees [11].

Enzyme additives

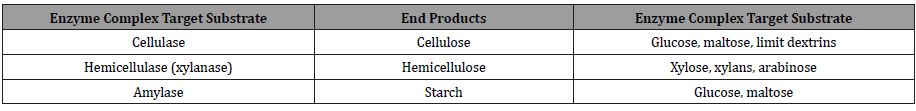

Enzymes are proteins that assist in metabolic processes. A variety of enzymes, particularly those that digest plant fiber and starch have used as silages additives. To date, we can find no evidence that would promote the use of protease enzymes as silage additives since they would most likely increase the concentration of rumen degradable protein in silage (an undesirable result). Silage additives may contain single enzyme complexes, combinations of enzyme complexes and combinations of enzyme complexes and LAB. There are two primary reasons for adding fiber-digesting enzymes to silage. First these enzymes could partially digest the plant cell walls (cellulose and hemicellulose) yielding soluble sugars which could be fermented by LAB to lower the silage pH. This would stimulate silage fermentation and improve fermentation quality by increasing the rate and extent of decline in pH, increasing the concentration of lactic acid, improving the lactic acid : acetic acid ratio (which is indicative of greater efficiency of fermentation), and hence reduce DM losses. A faster decline in pH would also limit degradation and deamination of forage proteins and reduce ammonia production. Second, partial digestion of the plant cell wall may improve the rate and/or extent of digestibility. In order for the first event to take place the rate of cellulose hydrolysis must coincide with early growth of lactic acid bacteria. For an improvement in digestibility, a change in the association of cell wall components must occur. (Amylase enzymes may provide substrates for LAB by partially digesting starch but would not degrade fiber).

The possibilities of using enzymes help to improve nutrient digestion, utilization, and animal productivity and at the same time reduce animal fecal material and pollution. Spraying enzymes onto forages just before feeding provides increased management flexibility for feeding and also bypasses any negative interactions that the ensiling process may have on silage enzyme performance.

When enzymes are sprayed onto silage before feeding, binding with substrates may help to protect these exogenous enzymes from ruminal degradation. Treating forages with enzymes in this manner may improve digestibility via a number of different mechanisms that including, direct hydrolysis, improvements in palatability, changes in gut viscosity, and changes in the site of digestion [11].

The enzyme amylase is useful for degrading starch into sugars. Cellulases or xylanases degrade cell walls into sugars. Sugars released by the enzymes increase growth of silage bacteria and, in some cases, fiber degrading enzymes also increase forage digestibility. These enzymes usually are most effective on low-lignin feedstuffs such as cereal silages and immature, cool-season grasses. Fiber-digesting enzymes have been most effective in reducing the fiber content of grass and alfalfa crops ensiled in the 60% to 70% moisture range [12].

Enzymes have improved fermentation by stimulating acid production, lowering pH, and lowering ammonia N. Just as bacterial inoculants require certain conditions for growth, enzymes require certain conditions for maximum activity. Most cellulase enzymes require a pH of 4.5 and temperature of 50˚C for optimal activity. Surface area, binding sites, moisture level and plant proteases may also inhibit enzyme activity [13].

Feed ingredients and by-products as additives

According to the report of Weiss, and Underwood [12] the incorporation of easily fermentable feed ingredients such as sugar or molasses to low DM sugar-limited tropical forages is a way to improve silage fermentation. Feed-grade products such as grains in general and processed by-products such as corn or sorghum meal, rice bran, cassava meal, citrus pulp, etc. can also be used as additives partly to provide fermentable substrate but also to direct the course of fermentation by absorbing excessive moisture [14].

Grain

According to the report of Weiss and Underwood [12] addition of grain to corn silage is not useful but adding it to hay crop silage has two benefits. First, adding grain to hay crop silage increases the energy content of the silage. This will reduce the amount of supplemental grain that has to be fed. If silage will be the main or only feed offered, then adding some grain to the forage at ensiling will make it a more complete feed. However, grain mixed with silage prior to ensiling or at feeding is nutritionally equal; therefore, if supplemental grain must be fed anyway, no true benefit is realized. Secondly, adding grain to forage will increase the dry matter content of the silage. Hay crops that are not wilted sufficiently prior to ensiling can cause seepage and result in an undesirable fermentation. Added grain may also make wet silage easier to unload from the silo [15].

Molasses

Cane molasses (75% DM) has been widely used added up to 10% w/w to provide fast fermentable carbohydrate for the ensilage of tropical herbages. Due to its viscosity it is difficult to apply and should be diluted preferably with a reduced volume of warm water to minimize seepage losses. When applied to tropical grasses molasses should be used in relatively high concentrations (4% to 5%) and with crops of very low DM content, a considerable proportion of the additive may be lost in the effluent during the first days of ensilage. However, according to the provision of extraneous sugar alone is not sufficient to permit the lactic acid bacteria to compete with other components of the silage micro flora and thus ensure preservation. So, under high moisture conditions molasses can also induce aclostridia spoilage especially with forages contaminated with soil [16].

Acids

Acids are added to forages at ensiling to cause an immediate drop in pH or to increase bunk life. Formic acid and mineral acids (sulfuric and hydrochloric) added at 10 - 30 lbs/wet ton will reduce pH quickly and greatly limit fermentation losses of protein and carbohydrates. Mineral acids are recommended the rapid acidification of the crop with a pH of about 3.5, which was originally thought to inhibit microbial and plant enzyme activity [13].

When acids are added, plant materials sink quickly and are easy to consolidate. Acidity may arrest plant respiration and reduce heat production and nutrient loss. Rapid acidification may also inhibit clostridia. However, addition of acids increases effluent and can be potentially toxic to animals. Furthermore, acids are corrosive to people, animals and machinery. Reduction of moisture content may minimize effluent, and addition of calcium carbonate can be used to adjust silage acidity [17].

Formic acid and/or formaldehyde treatments

Commercial formic acid (85%) has been extensively used for the ensilage of un wilted temperate grasses but is gradually being substituted by biological additives, certainly because it is unsafe in handling and application and corrosive to equipment. Information about the use of such additives on tropical forages is limited to research data and no literature was found reporting farm-scale adoption. Earlier studies by with the production of young, highprotein, low DM elephant grass have shown that a 0.8% rate of formic acid is needed for a reasonably good silage fermentation, while found no effectiveness based on silage composition when applying formic acid at various rates to un wilted or wilted elephant grass. On the other hand, 0.5% formic acid treated elephant grass had not only an improved fermentation but also higher intake and digestibility as compared to the untreated control [18].

Propionic acid

It is the short-chain fatty acids; prop ionic acid has the greatest anti mycotic activity. It is weaker than formic and mineral acids but can be a useful additive for silages. Prop ionic acid is effective in reducing yeast and molds which are responsible for aerobic deterioration in silages. The antimycotic effect of prop ionic acid is enhanced as pH declines, making it an ideal candidate for improving the aerobic stability of corn silage where pH is low. In the past, aerobic stability was improved when large amounts of prop ionic acid (1% to 2% of the DM) were added to silage, but the high percentage of acid often restricted fermentation in these cases. The application rate of prop ionic acid additives has varied depending on moisture content of the forage, length of storage and formulation with other preservatives [19].

Nutrient Additives

Ammonia and urea

Anhydrous ammonia or water- or molasses-ammonia mixes have been used as silage additives. Ammonia additions have resulted in a) addition of an economical source of crude protein b) prolonged bunk life during feeding (aerobic stability, c) less molding and heating during ensiling; and d) decreased protein degradation in the silo [20].

Urea has been added to corn silage as an economical source of crude protein. However, a beneficial effect of urea on improved bunk life and decrease in proteolysis has not been totally substantiated. Whenever ammonia or urea is added to the diet, special attention should be made to ensure that degradable and un degradable protein requirements are balance for the target ruminant animal [20].

Ammonia has been used to treat corn silage, small cereal grain silage and high moisture corn with varying degrees of success. Although some have used ammonia on alfalfa silage, this practice is not recommended [11]. Addition of anhydrous ammonia or waterammonia mixes initially buffers the plant material (Table 3).

Table 3: Enzymes used as silage additives.

Minerals

Minerals such as calcium, phosphorous, sulfur and magnesium have been added to forage at the time of ensiling. Usually these either have no effect on fermentation or act as buffers resulting in higher pH silage. The only reason for adding minerals at the time of ensiling is if the silage will be the only feed offered to the animals. Addition of minerals will make the silage more nutritionally complete. If concentrates are going to be supplemented, it is better to add the minerals to the concentrate mix . Salt is also a mineral additive. The addition of 1% sodium chloride to a mixture of wilted elephant grass and cassava tops (28% DM, 9.5% WSC) was not effective to improve fermentation of silage as compared to the un wilted control [20].

Conclusion

To ensure good animal health and growth, it is essential to produce feed having high nutritive value and microbiological quality. Silage additives can be useful tools to improve silage quality (increase nutritional content) and animal performance (milk [quantity and/or composition], gain, body condition, reproduction), or decrease heating and molding during storage and fadeout; however, they are not replacements for good management practices. Silage additives will not make poor quality forage in to good, but they can help make good quality forage into excellent quality silage. Silage additives can be beneficial and economical to use. Producers should use silage additives that are supported with published data. Microbial inoculants have improved the nutritive value of silages, but enzymes have been inconsistent. Effects of microbial inoculants on aerobic stability have also been inconsistent. Anhydrous ammonia and prop ionic acid can improve the aerobic stability of silages, but their use is not widespread due to difficult handling and cost, respectively. To make the best silage always use an additive is a good recommendation if care should be taken when choosing a silage additive and follows the product’s direction properly. In order for a silage additive to be useful it must increase DM (nutrient) recovery, improve animal performance (milk [quantity and/or composition], gain, body condition, reproduction), or 3) decrease heating and molding during storage and feed out.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Zehra Sariçiçek B, Ünal KILIÇ (2009) The Effects of Different Additives on Silage Gas Production, Fermantation Kinetics and Silage Quality. Ozean Journal of Applied Sciences 2: 1943-2429.

- Lattemae P, Laats A, U Tamm (2006) The Technological Factors Affecting the Quality of Big Bale Silag.

- Oliveira AS (1995) Rapid pH Reductions in Silages. Revista Brasileira de Saúde e Produção Animal, Salvador, pp. 1-5.

- Kenilworth, Warwickshire Silage Additives (2012) Dairy Co. Agriculture and Horticulture Development Board, Stoneleigh Park.

- McDonald P, Henderson AR, Heron SJE (1991) The Biochemistry of Silage. 2nd Chalcombe Publications, Marlow, Bucks.

- Stewart WM (2011) Plant Nutrition Today. From Scientific Staff of the International Plant Nutrition Institute (IPNI), Norcross, Georgia.

- Meeske R (2005) Silage Additives: Do They Make a Difference? Vol. 6, Department of Agriculture Western Cape, Elsenburg, X1, SA-ANIM SCI, South Africa.

- Merry RJ, Cussen-MacKenna RF, Williams AP, Tweed JKS (1993) The Effect of Different Inoculants on Fermentation and Proteolysis in Silages of Differing Perennial Ryegrass and White Clover Content. Proceedings of the 10th International silage Conference, Dublin, pp. 83.

- Pahlow G, Honig H (1996) The German Silage Additive Approval Scheme. Proceedings of the 11th International Silage Conference, Aberystwyth, pp. 146-147.

- Dawson TE (1994) Propionic Acid-Producing Bacteria as Bioinoculants for the Preservation of Ensiled High-Moisture Corn. Ph.D. Dissertation, Michigan State University, East Lansing.

- Kung Jr L (2010) A Review on Silage Additives and Enzymes. Department of Animal and Food Sciences University of Delaware Newark, DE 19717-1303.

- Weiss B, Underwood J (2009) Silage Additives. Ohio State University Extension Department of Horticulture and Crop Science, Columbus.

- Liu JX, Guo J (2010) Ensiling Crop Residues. Zhejiang University and China National Breeding Stock Import and Export Corporation.

- Cheng Y, Chen C, Peng P (2001) Effects of Different Additives on Silage Quality of Napiergrass. Proceedings of the 19th International Grassland Congress, San Pedro, pp. 11-21.

- Bolsen KK (1999) Silage Management in North America in the 1990s. In: Lyons, T.P. and Jacques, K.A., Eds., Biotechnology in the Feed Industry, Proceedings of the 15th Annual Symposium, Nottingham University Press, Nottingham, pp. 233-244.

- Filya I, Sucu E (2002) Effects of Enzyme-Lactic Acid Bacteria Mixture Silage Inoculants on the Fermentation, Aerobic Stability, Cell-Wall Content, and in Situ Rumen Degradability of Wheat, Sorghum and Maize Silages in Turkey. Proceedings of the 13th International Silage Conference, pp. 11-13.

- Filya I, Hanoglu H, Sucu E, Karabulut A (2002) Ensiling Maize with Biological Additives in Large Containers. Proceedings of the 13th International Silage Conference, pp. 11-13.

- Meeske R, van der Merwe GD, Greyling JF, Cruywagen CW (2003) The Effect of the Addition of a Lactic Acid Bacterial Inoculant to Maize at Ensiling on Silage Composition, Silage Intake, Milk Production and Milk Composition. South African Journal of Animal Science 32(4): 263-270.

- Meeske R, van der Merwe GD, Greyling JF, Cruywagen CW (2022) The Effect of Adding an Enzyme Containing Lactic Acid Bacterial Inoculant to Big Round Bale Oat Silage on Intake, Milk Production and Milk Composition of Jersey Cows. Animal Feed Science and Technology 97: 159-167.

- Thaysen J, Sudekum KH, Susenbeth A, Engelhard T, Wulfes R (2002) Effects of Lacic Acid Bacteria (Lactobacillus plantarum), Molasses and Their Combination on the Quality of Grass and Maize Silages and the Performance of Dairy Cows. Proceedings of the 13th International Silage Conference, pp. 11-13.

-

Mebrate Getabalew, Asebu Mindaye and Tewodros Alemneh*. Silage and Enzyme Additives as Animal Feed and Animals Response. Arch Animal Husb & Dairy Sci. 2(4): 2022. AAHDS.MS.ID.000543.

-

Silage, Silage additives, Enzymes, Fermentation, Inoculants, Lactic acid, Bacteria, Palatable, Concentrates

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.